Tire sidewall rubber composite material and preparation method thereof

A composite material and sidewall rubber technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of reddish-brown color on the sidewall surface, affecting the appearance quality of tires, etc., and achieve good thermal oxidation aging performance, Guarantee the appearance quality requirements and ensure the effect of basic mechanical performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

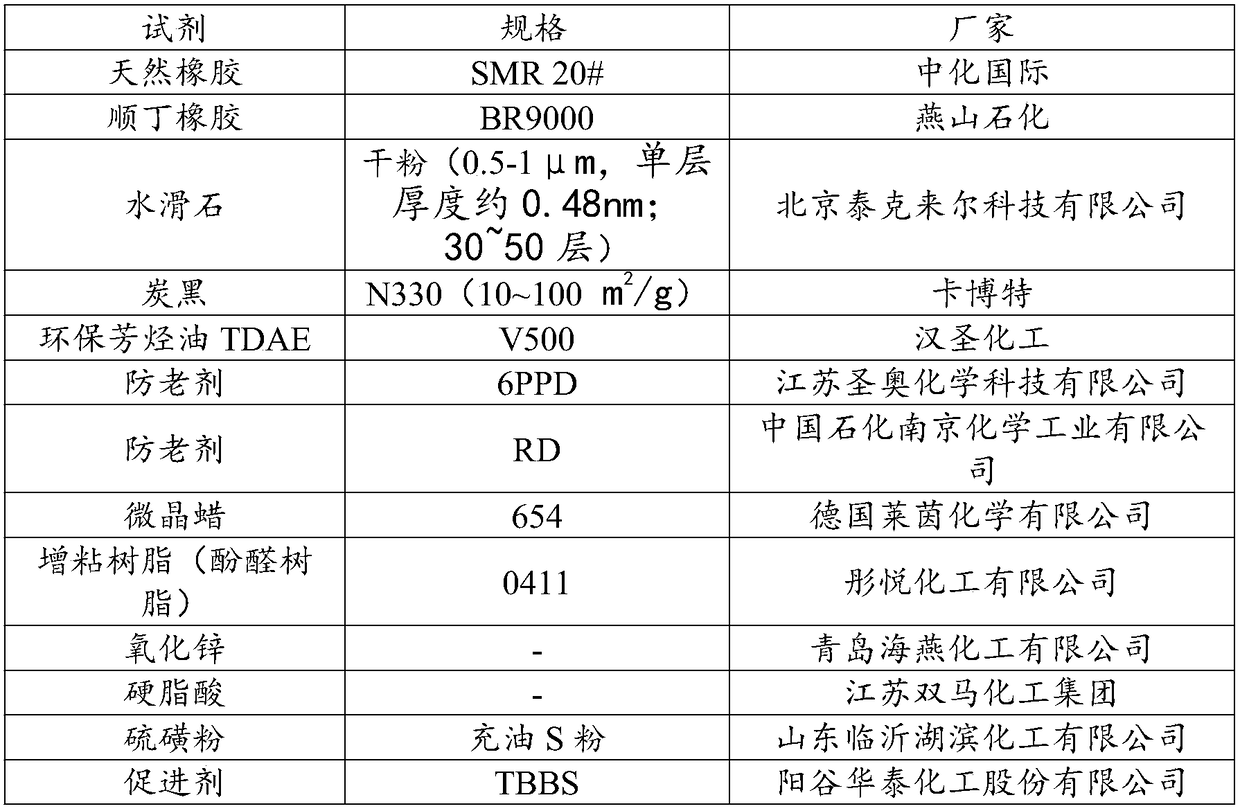

preparation example Construction

[0052] In a specific embodiment of the present invention, the present invention provides a method for preparing the sidewall rubber composite material, comprising the following steps: masticating rubber in an internal mixer for 20 to 50 seconds; then adding hydrotalcite and carbon black in sequence , environmentally friendly aromatic oil, zinc oxide, stearic acid, tackifying resin, anti-aging agent 6PPD, anti-aging agent RD and wax for mixing; when the temperature in the internal mixer reaches 120-125 °C, lift the mound once; when the temperature reaches 150 At ~160°C, remove the glue to get the mixed rubber; after cooling at room temperature for 8 hours, put the mixed rubber in the open mill, add oil-extended sulfur powder and accelerator, and mix; after mixing evenly, roll it up 4 to 5 times ; Thin through 5 to 8 times to get the tire sidewall rubber composite material.

[0053] In a preferred embodiment of the present invention, the present invention provides a method for p...

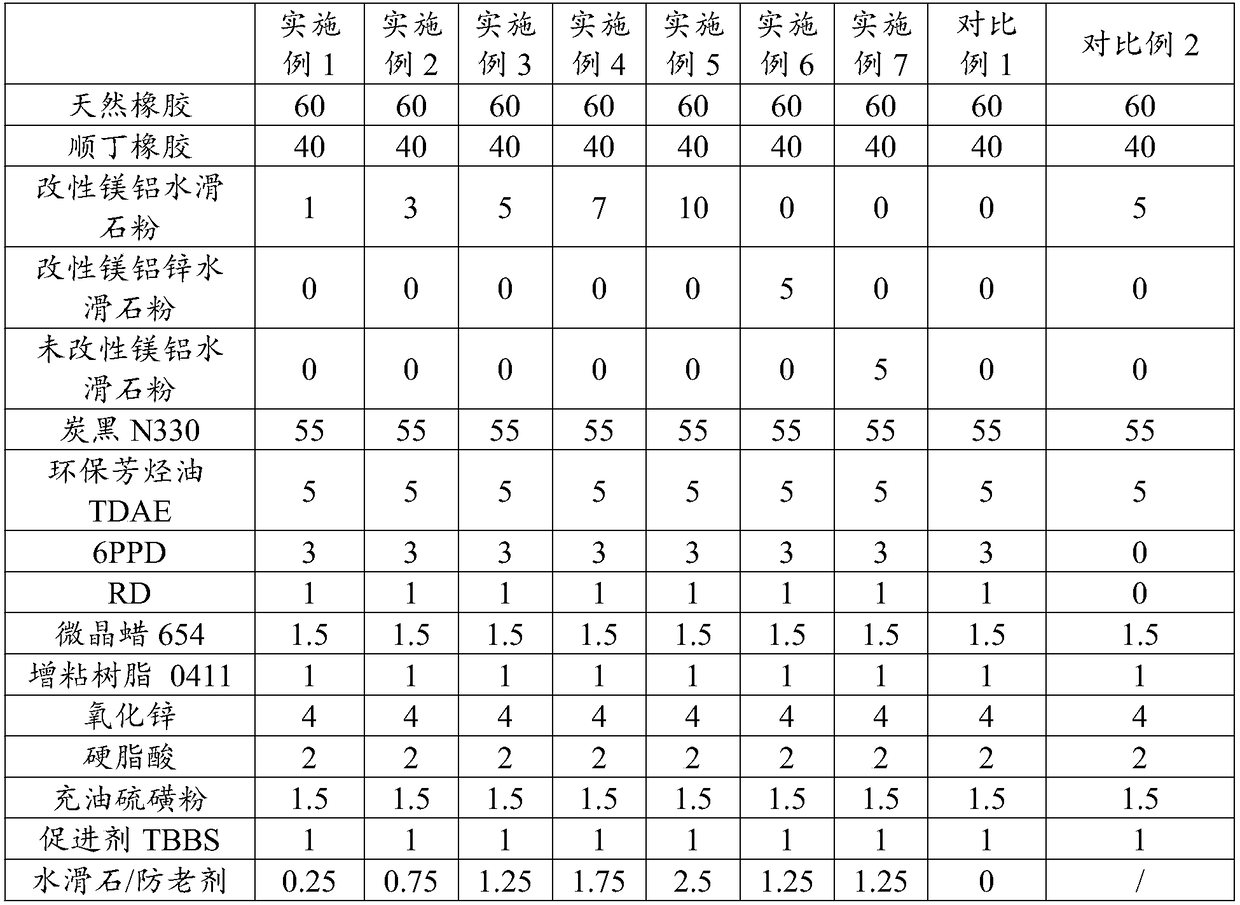

Embodiment 1

[0064] According to the ratio of each component in Table 3, set the mixer speed to 80rpm, the initial temperature in the mixer is 60°C, masticate the natural rubber and butadiene rubber in the mixer for 40 seconds, and then mix the organic Modified magnesium aluminum hydrotalcite powder (1 weight part), carbon black N330, environment-friendly aromatic oil (TDAE), zinc oxide, stearic acid, tertiary butylphenolic resin 0411, anti-aging agent 6PPD, anti-aging agent RD and microcrystalline wax input Carry out mixing in the internal mixer, and when the temperature in the internal mixer reaches 125°C, lift the top bolt for 10 seconds, then press down the top bolt, and when the temperature in the internal mixer is 155°C, the glue is removed to obtain a stage of mixing rubber; after a section of mixed rubber is parked and cooled at room temperature for 8 hours, sulfur powder and accelerator TBBS are added to the two-roll mill, and after mixing until all components are dispersed into th...

Embodiment 2

[0066] According to the ratio of each component in Table 3, set the speed of the internal mixer to 100rpm, and the initial temperature in the internal mixer to be 60°C, masticate the natural rubber and butadiene rubber in the internal mixer for 20 seconds, and then mix the organic Modified magnesium aluminum hydrotalcite powder (3 parts by weight), carbon black N330, environmentally friendly aromatic oil (TDAE), zinc oxide, stearic acid, tert-butylphenolic resin 0411, anti-aging agent 6PPD, anti-aging agent RD and microcrystalline wax input Carry out mixing in the internal mixer, and when the temperature in the internal mixer reaches 120°C, lift the top bolt for 5 seconds, then press down the top bolt, and when the temperature in the internal mixer is 160°C, the rubber is discharged to obtain a stage of mixing rubber; after a section of mixed rubber is parked and cooled at room temperature for 8 hours, add sulfur powder and accelerator TBBS on a two-roll mill, mix until all com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com