Numerical control machine tool capable of quenching and tempering simultaneously at high frequency

A CNC machine tool and high-frequency quenching technology, which is applied in the direction of quenching device, energy efficiency improvement, process efficiency improvement, etc., can solve the problems of unsuitable quality control, low efficiency, high labor intensity, etc., and achieve the reduction of repeated processes of upper and lower workpieces, The effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

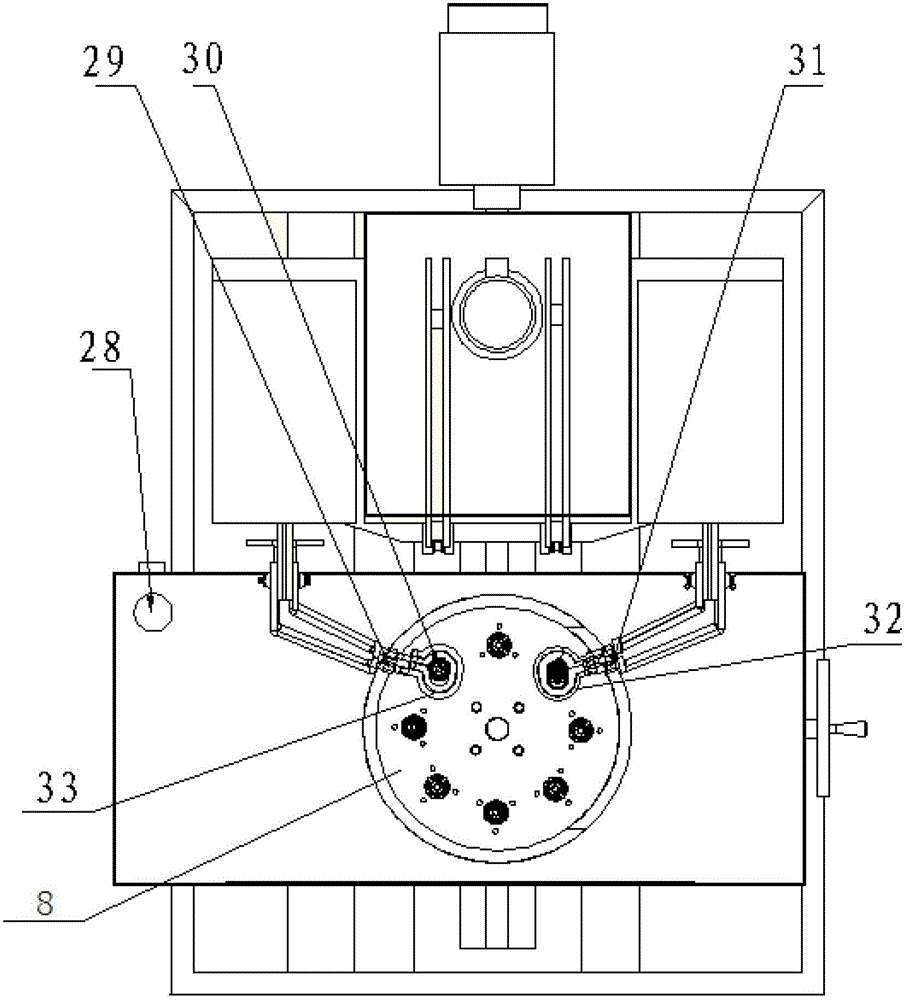

[0021] Such as figure 1 with figure 2 Shown, a kind of simultaneous high-frequency quenching and tempering numerical control machine tool includes circuit part and mechanical part, and described circuit part comprises: numerical control system control module, quenching and tempering system control module, machine tool control terminal, quenching induction coil control wiring Terminal, tempering induction coil control terminal, wire bundle; the mechanical part includes: machine tool main body 1, auxiliary cabinet, numerical control console and eight-station rotary workpiece fixture disk indexing and rotating mechanism 8; the auxiliary cabinet has three floors Structure, the upper layer has a quenching high-frequency power supply and tempering high-frequency power supply, the middle layer has a built-in quenching liquid circulation pump and cooling water circulation pump, and the lower layer has a built-in quenching liquid tank and cooling water tank; the CNC console is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com