Step-link shaft superaudio induction quenching method and special induction coil thereof

An induction coil and induction hardening technology, which is applied in the field of ultrasonic frequency induction hardening of step shafts, can solve the problems of low production efficiency, overheating at sharp corners, and induction hardening cracking of step shafts, so as to shorten the processing cycle, reduce production costs, and ensure Effect of hardened layer depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments so that those skilled in the art can better understand the technical solution of the present invention.

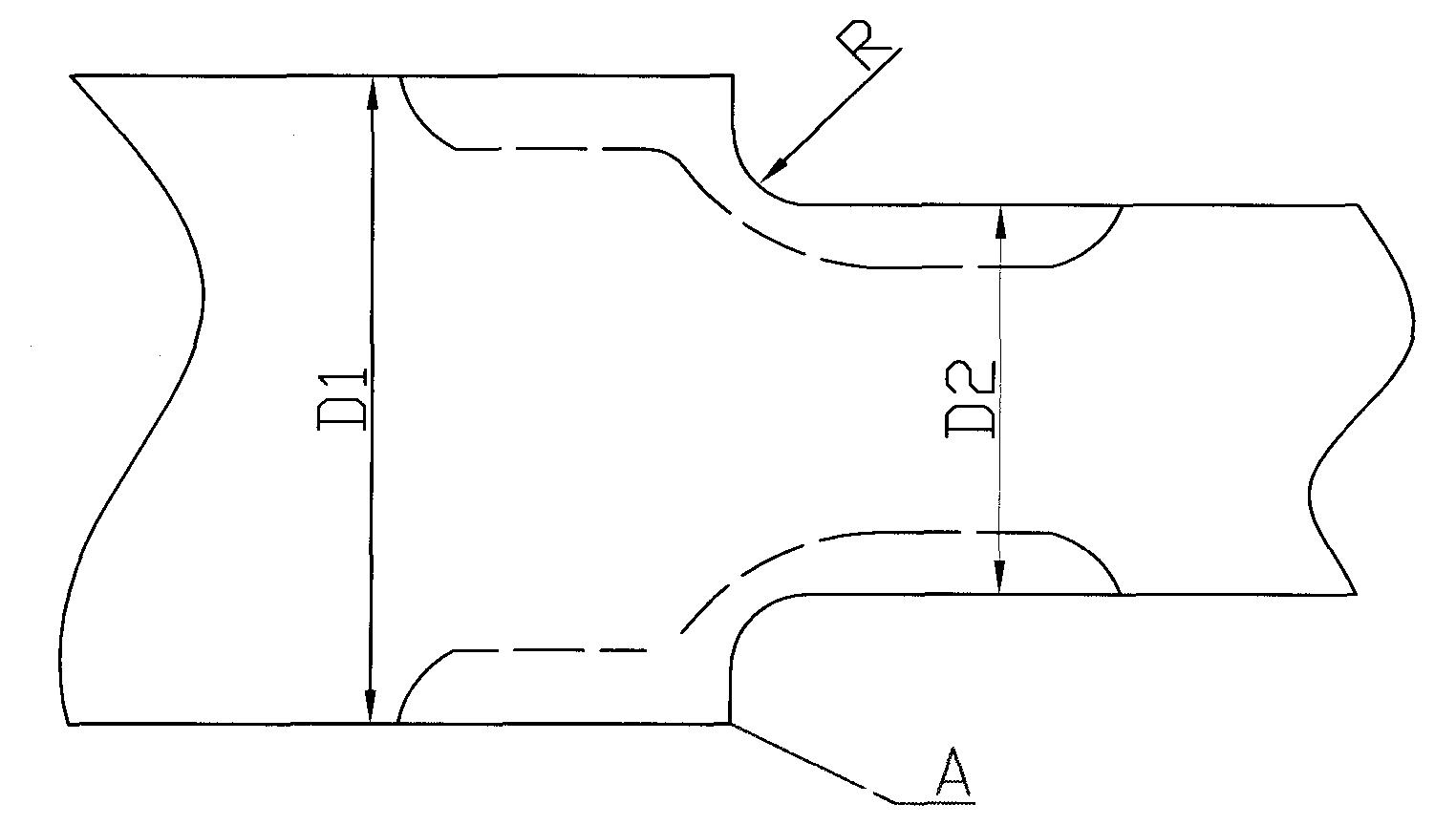

[0026] like figure 1 The step shaft shown includes a large-diameter shaft and a small-diameter shaft, and there is an excessive fillet between the large-diameter shaft and the small-diameter shaft. The present invention is used for the method of supersonic induction hardening of the above-mentioned step shaft, and a suitable induction hardening is selected according to the large-diameter shaft. Coil, then wrap the induction coil on the part that needs to be quenched, and make the step shaft rotate, the input voltage is 380V, the input power of the super-audio induction heating power supply is 150KW-250KW, and the oscillation frequency of the super-audio frequency induction heating power supply is 25 -40KHZ.

[0027] The method for s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com