Industrial aluminum ash recycling method

An aluminum ash and industrial technology, which is applied in the field of harmless treatment and resource utilization of hazardous waste, can solve the problems of high energy consumption, large reuse limitations, and low content of effective substances in the recycling process of aluminum ash, achieving Significant social and economic benefits, simple process, and high effective substance content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

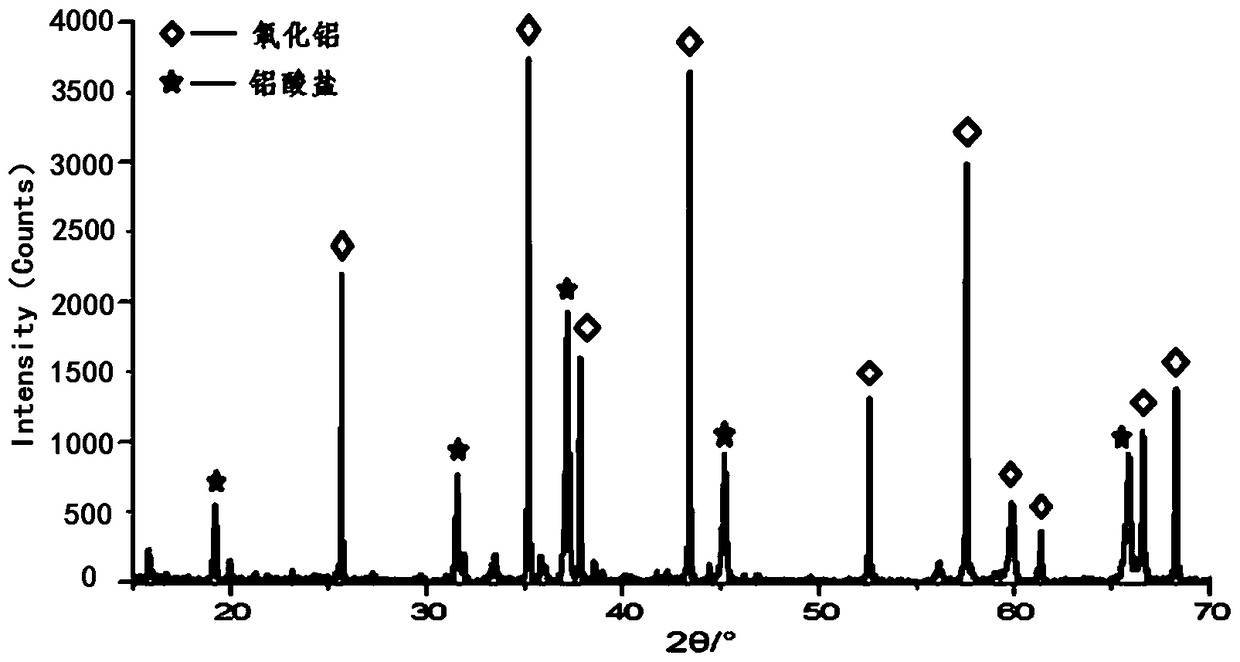

[0024] A method for recycling industrial aluminum ash. The specific process steps of the method are: directly grind the aluminum ash to 270 mesh with a grinder; then put the ground powder into a regeneration furnace, and activate and regenerate it at a temperature of 1100°C 15h; after discharging, dump the regenerated powder into a pool for cooling water washing 12 times, each time the liquid-solid mass ratio is 1:7, and the washing water is recycled; the washed raw material is dried at 150°C to obtain the recycled industrial raw material A, Its XRD pattern is as follows figure 1 shown. According to the XRF component test, the alumina content in the recycled industrial raw material A is ≥80%, and the Na+K content is <1%. Recycled industrial raw material A has a wide range of applications, and can be used as a raw material in refractory materials, ceramic materials, abrasive materials, thermal insulation materials, and coarse industrial alumina industries.

Embodiment 2

[0026] A method for recycling industrial aluminum ash, which mainly includes the following process steps: mixing aluminum ash and high-purity silicon dioxide in proportions of 60% and 40% respectively, grinding the mixture to 325 meshes with a grinder; Put the powder into the regeneration furnace, activate and regenerate at 500°C for 24 hours; after discharging, pour the powder into a cold water pool for washing 15 times, each time the liquid-solid mass ratio is 1:10, and the washing water is recycled; after washing The raw material is dried at 200°C to obtain the recycled industrial raw material B. The XRF component test of the recycled industrial raw material B shows that the alumina content is ≥50%, and the Na+K content is <1%. This raw material can also be used in refractory materials, ceramic materials, Abrasive materials, thermal insulation materials, and coarse-grade industrial alumina industries are used as raw materials.

Embodiment 3

[0028] A method for recycling industrial aluminum ash, which mainly includes the following steps: mixing aluminum ash, aluminum hydroxide, and nano-α-alumina in proportions of 50%, 30%, and 20% respectively, and grinding the mixture to 200 mesh with a grinder ; Then put the ground powder into the regeneration furnace, and activate and regenerate at 800°C for 20 hours; after discharging, pour the powder into a cold water pool for washing 10 times, each time the liquid-solid mass ratio is 1:6, The washing water is recycled; and then dried at 80°C to obtain the recycled industrial raw material C. According to the XRF composition test, the alumina content in recycled industrial raw material C is ≥95%, and the Na+K content is less than 1%. This raw material can be used as a raw material in refractory materials, ceramic materials, abrasive materials, thermal insulation materials, and coarse industrial alumina .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com