Physical battery and production method thereof

A technology of physical battery and manufacturing method, which is applied to fixed capacitor electrodes, components of fixed capacitors, fixed capacitor dielectrics, etc. Stable and reliable effect of withstand voltage strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

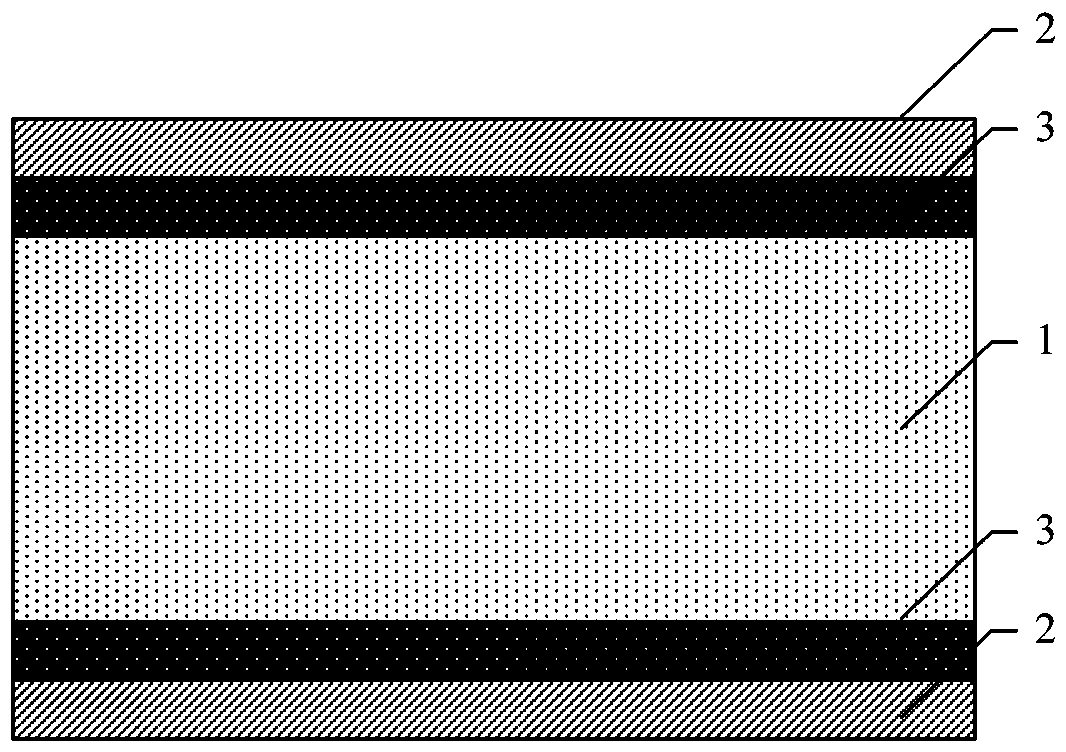

[0024] refer to figure 1 As shown, the present invention discloses a physical battery based on sheet-type titanium dioxide, including an aluminum film as an upper and lower electrode layer 2 and a titanium dioxide as an intermediate dielectric layer 1, and the electrode layer 2 and the dielectric layer 1 are also provided with a Titanium oxide layer 3, the thickness of the aluminum film is 8 microns, the beneficial effect of choosing this thickness is that the electrode cost is low, and can meet the requirements of high current charging and discharging, the titanium dioxide is 50-500 microns in diameter and 1- 20-micron sheet-type titanium dioxide with a complete structure, the thickness of the aluminum film is 8 microns, so that the separation of materials is less difficult, the size is easy to control, and the success rate of tape-casting is high.

[0025]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com