Testing system of external pressure resistance of lining steel pipe of water tunnel

A technology of water conveyance tunnel and testing system, which is applied in the direction of applying stable tension/pressure to test material strength, measuring devices, strength characteristics, etc., and can solve problems such as differences in buckling resistance, inconvenient lifting and installation, and inconsistent distribution modes. Achieve the effects of reducing material costs, facilitating hoisting and handling, and reducing head loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and embodiment can not be repeated here one by one, but implementation mode of the present invention is not therefore limited to following embodiment:

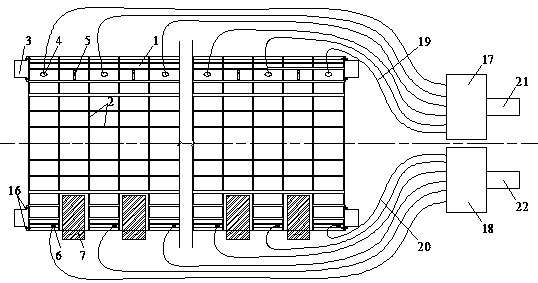

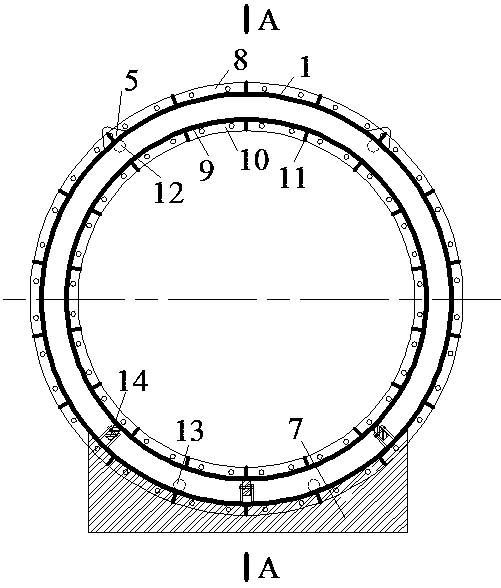

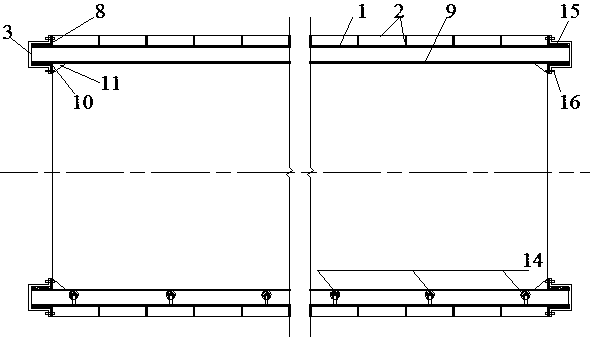

[0050] Such as Figure 1~Figure 3 As shown, the external pressure resistance test system of the steel pipe lined in the water delivery tunnel of this embodiment includes a steel sleeve 1, a plugging end cover 3, a test steel pipe 9, a buttress 7, a water injection flower pipe 12, a drainage flower pipe 13, Rubber gasket 15, booster pump 17, water pump 18, water inlet pipe 19, water outlet pipe 20, booster control device 21 and pressure reduction control device 22, wherein:

[0051] The steel sleeve 1 is a container for applying external water pressure. It is a cylinder with a total length of 36m and an inner diameter of 5.4m, and a wall thickness of 28mm. Each is provided with 6 water inject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com