A dismantling system and construction method of a translational system after a building is translated

A technology of translation system and construction method, applied in building construction, construction, building maintenance and other directions, can solve the problems of inconvenience and inconvenience of cutting and dismantling tools, so as to solve the problem of dismantling, save costs and ensure safe operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

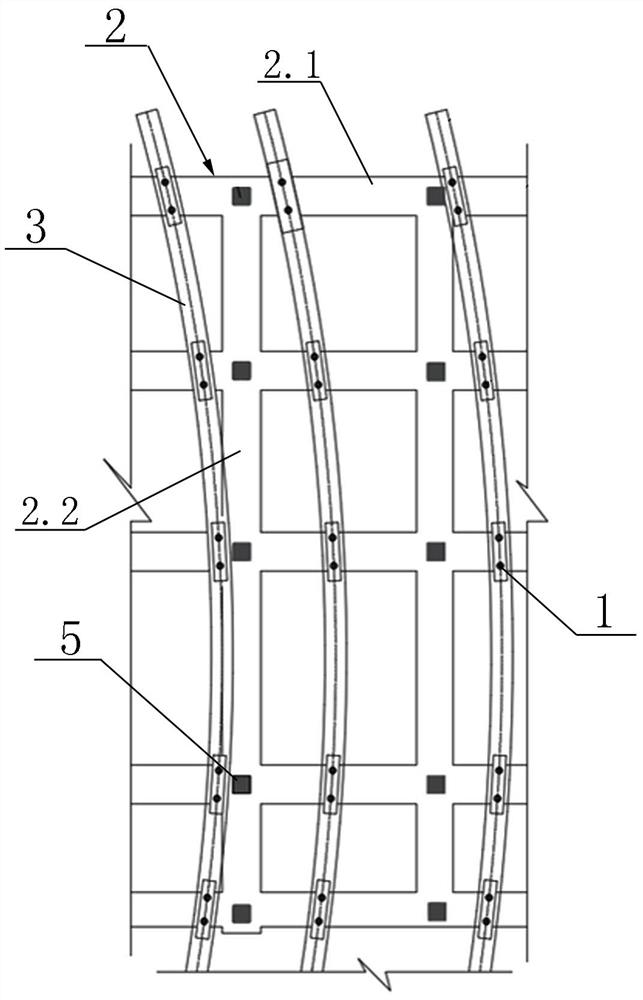

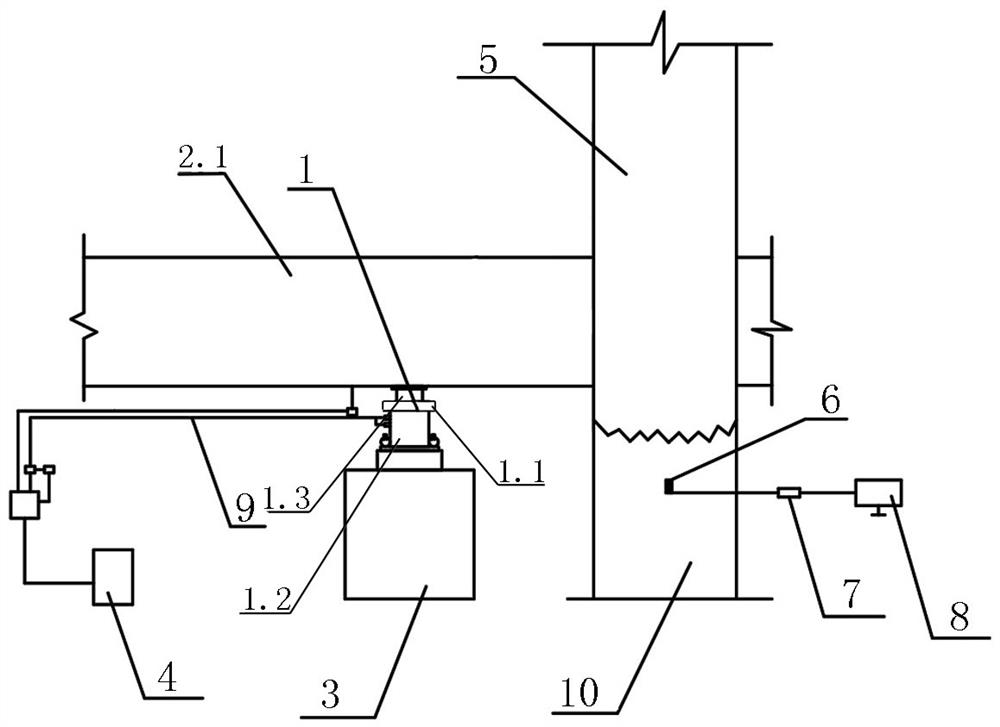

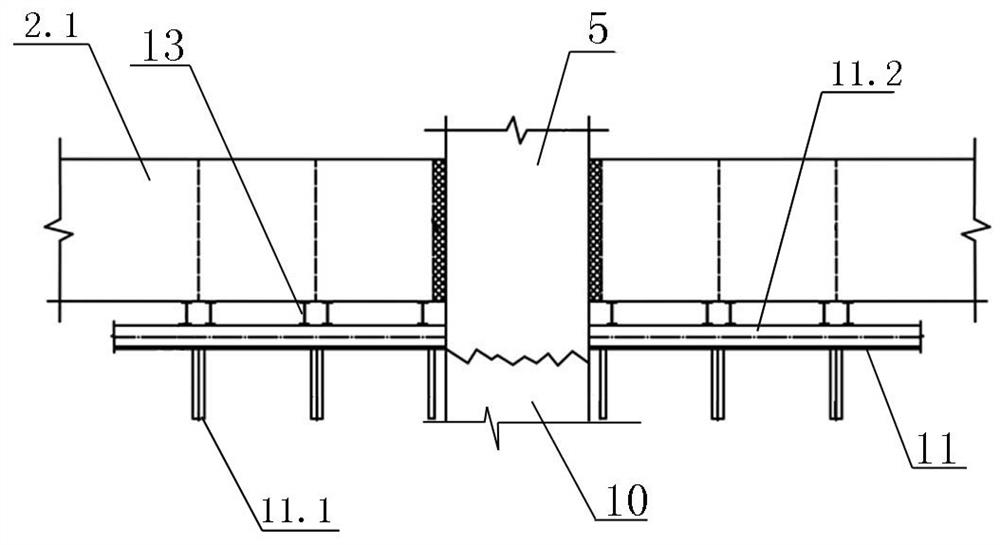

[0038] Such as Figure 1-5 As shown, the dismantling system of the translation system after the building is translated, the translation system includes track beams 3, jacks 1 and pallet beams 2; the track beams 3 have one group, arranged at the bottom of the translation building along the lateral interval, and Each track beam 3 is arranged along the translation direction of the translation building; the pallet beam 2 is supported on the bottom of the translation building, and is connected with the original vertical member 5 of the translation building; the original vertical member of the translation building 5 is provided with a new vertical member 10 at the bottom; the jacks 1 are arranged at intervals on the track beam 3, and the upper end of the jack 1 is pushed against the bottom of the pallet beam 2; it is characterized in that: the demolition system includes a PLC synchronous control pump Station 4, stress strain gauge 6, strain gauge 7, display device 8, support frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com