Sleeve grouting material for negative temperature reinforcing steel bar connection and preparation method thereof

A technology of sleeve grouting and warm type, which is applied in the field of negative temperature sleeve grouting material and its preparation, can solve the constraints of the use scene and application range of sleeve grouting material for steel bar connection, cannot meet the lower temperature environment, and affect the steel bar Problems such as connection quality at joints can be achieved to reduce construction costs, ensure structural safety, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

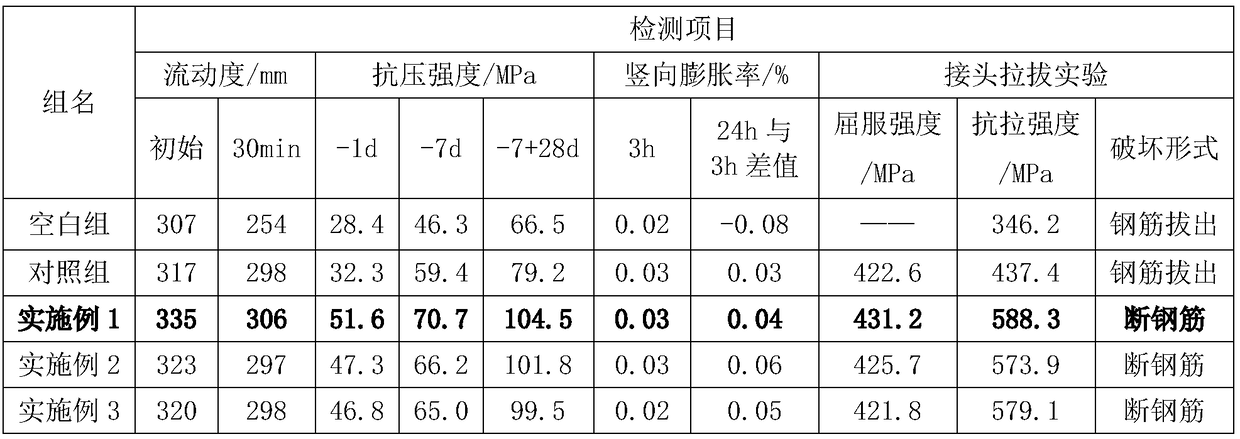

Embodiment 1~3、 comparative example 1~2

[0036] The sleeve grouting material for the connection of negative temperature type steel bars prepared in Examples 1~3 and Comparative Examples 1~2 comprises 20% of ordinary cement, 25% of special cement, 43% of aggregate, and 7.7% of modified admixture by weight percentage , 0.05% of the early expansion component, 3.2% of the middle and late expansion component, 0.6% of antifreeze, and 0.45% of the functional component; wherein, the component ratio of the modified admixture is shown in Table 1 below.

[0037] The modified admixture raw material list of the sleeve grouting material for negative temperature type steel bar connection prepared in Table 1 embodiment 1~3, comparative example 1~2, unit: %

[0038] group name

Embodiment 4~5、 comparative example 3~4

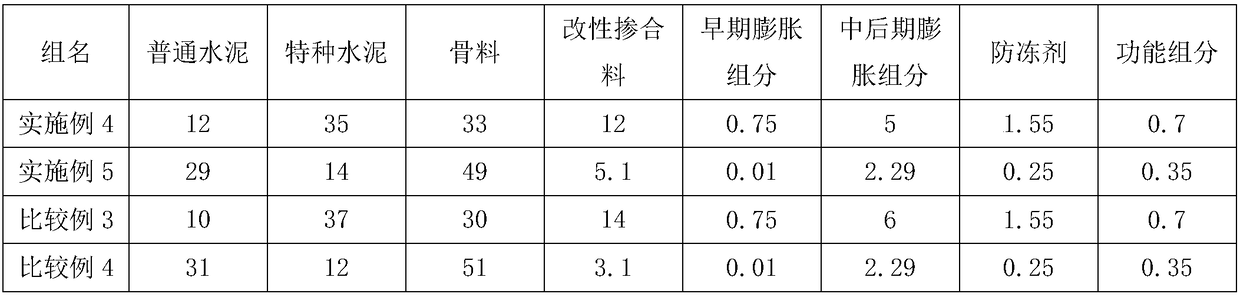

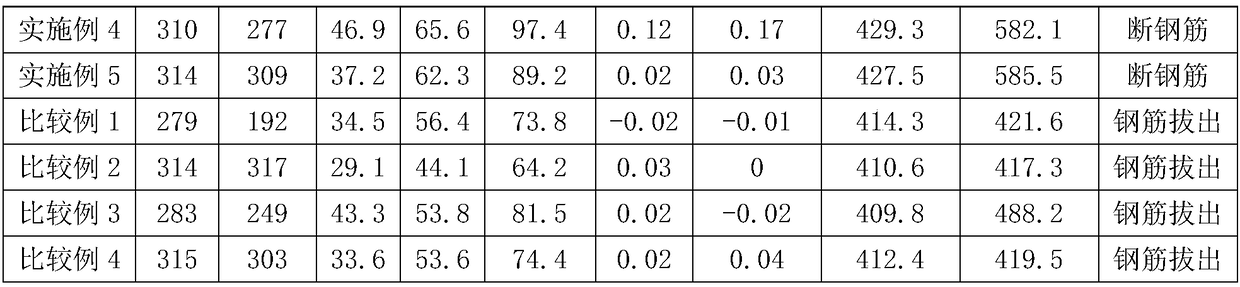

[0040]The sleeve grouting materials for negative temperature steel bar connections prepared in Examples 4 to 5 and Comparative Examples 3 to 4 include ordinary cement, special cement, aggregate, modified admixture, early expansion component, and middle and late expansion component , antifreeze, functional components, the ratio of each raw material by weight percentage is shown in Table 2 below. Among them, the modified admixture is compounded by grinding 3.8% of organic silane coupling agent, 90.5% of modified nano silicon dioxide and 5.7% of ultrafine slag powder by weight percentage.

[0041] Table 2 The table of raw materials prepared by embodiment 4~5, comparative example 3~4, unit: %

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com