A flexible screen bonding method based on numerical simulation of finite element model

A technology of numerical simulation and flexible screen, applied in the field of finite element analysis, it can solve the problems of different force conditions, only obtaining, bending damage, etc., so as to ensure the accuracy of fitting simulation, reduce the cost of experiments, and reduce the consumption of calculation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

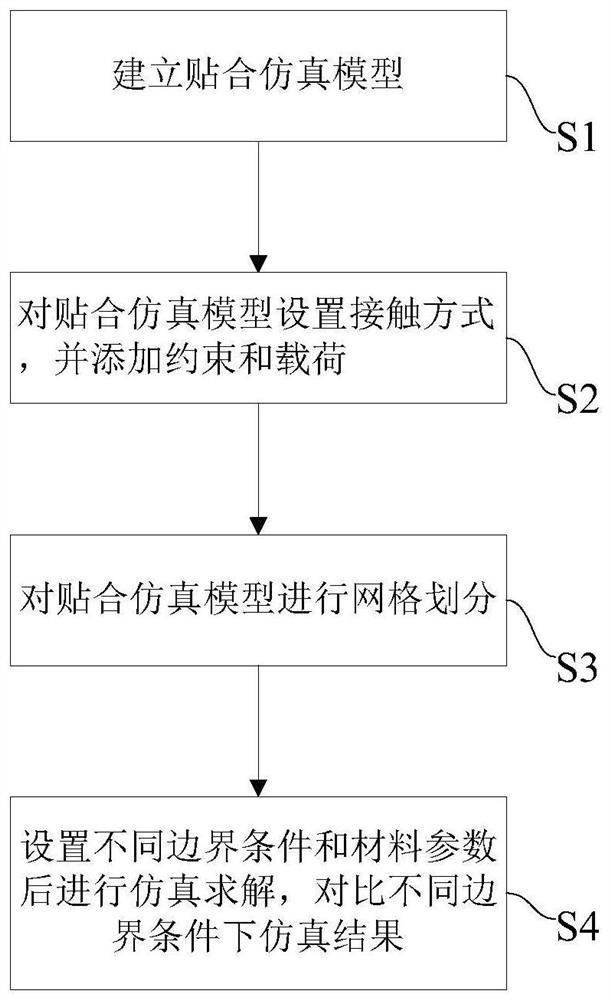

[0038] A flexible screen bonding method based on numerical simulation of a finite element model, comprising the following steps:

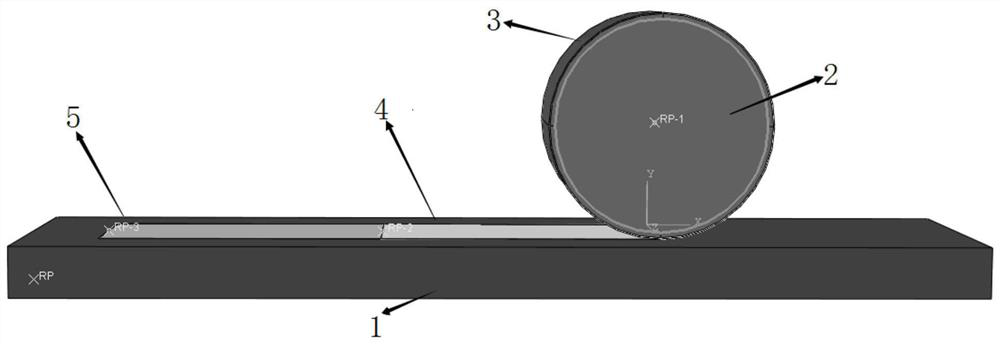

[0039] Step 1. Establish three-dimensional models of the bonding platform Stage, Panel, SUS, roller Drum, and roller outer ring Sheet and assign material properties.

[0040] In step 2, specify the fitting platform Stage and the roller Drum as discrete rigid bodies, and the Panel, SUS, and roller outer ring Sheet as deformable flexible bodies. And assign material properties and dimensions to them respectively.

[0041] Step 3, assemble the model, ①Roller Drum is in contact with the outer ring Sheet of the roller and is concentric; ②Roller Drum is symmetrical to the center of the fitting platform Stage; ③Panel is symmetrical to the center of the fitting platform Stage; ④The roller outer ring Sheet is aligned with the outer endpoint of the Panel Cut; ⑤Panel is in contact with the bonding platform Stage; ⑥SUS is in contact with the bonding platform S...

Embodiment 2

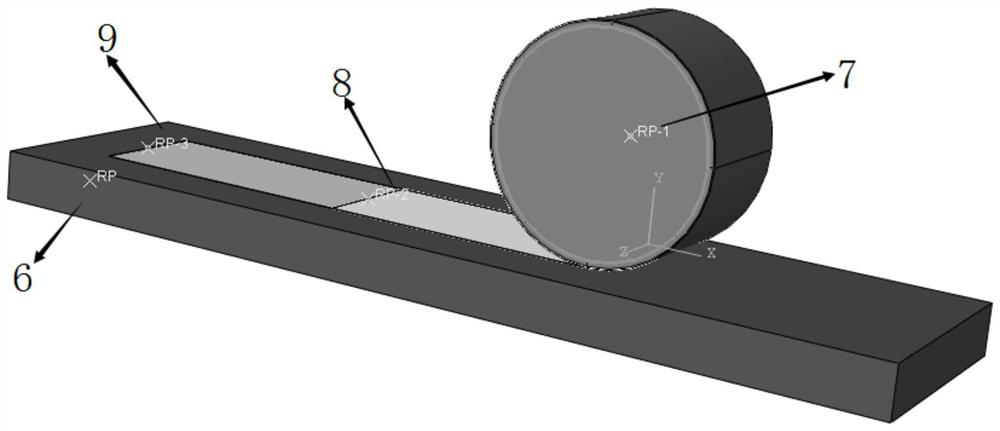

[0060] A flexible screen bonding method based on numerical simulation of a finite element model, comprising the following steps:

[0061] Step 1. Establish three-dimensional models of the bonding platform Stage, Panel, SUS, roller Drum, roller outer ring Sheet, and OCA and assign material properties.

[0062] In step 2, specify the bonding platform Stage and the roller Drum as discrete rigid bodies, and the Panel, SUS, roller outer ring Sheet, and OCA optical glue as deformable flexible bodies, and specify material properties and dimensions for them respectively.

[0063] Step 3, assemble the model, ①Roller Drum is in contact with the outer ring Sheet of the roller and is concentric; ②Roller Drum is symmetrical to the center of the fitting platform Stage; ③Panel is symmetrical to the center of the fitting platform Stage; ④The roller outer ring Sheet is aligned with the outer endpoint of the Panel Cut; ⑤Panel is in contact with the bonding platform Stage; ⑥SUS is in contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com