High-volume light-weight graphene catalysis rare earth aluminum magnesium based hydrogen storage material and preparation method thereof

A hydrogen storage material and graphene technology, applied in the field of hydrogen storage materials, can solve the problems of difficult to achieve rapid charging and discharging, high thermodynamic stability, harsh conditions for hydrogen absorption and desorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

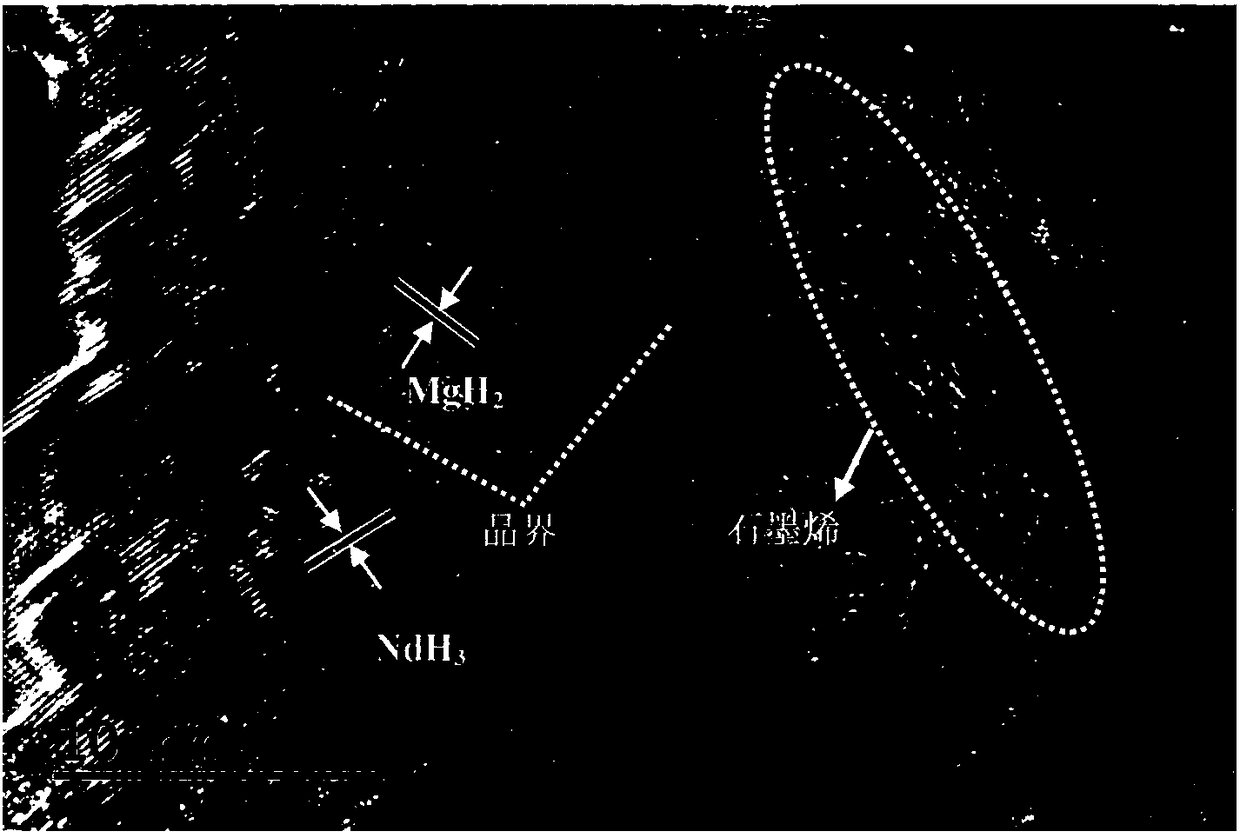

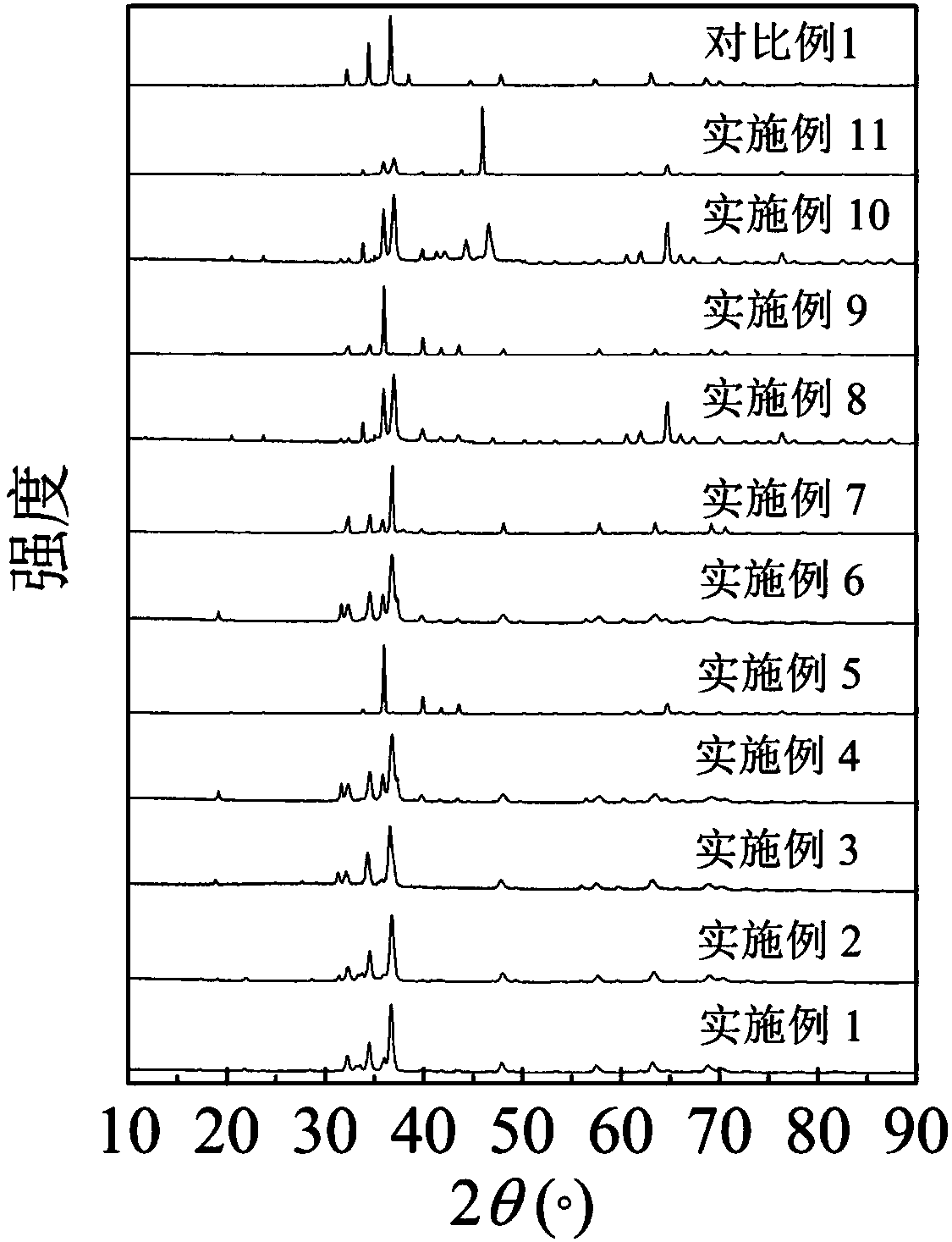

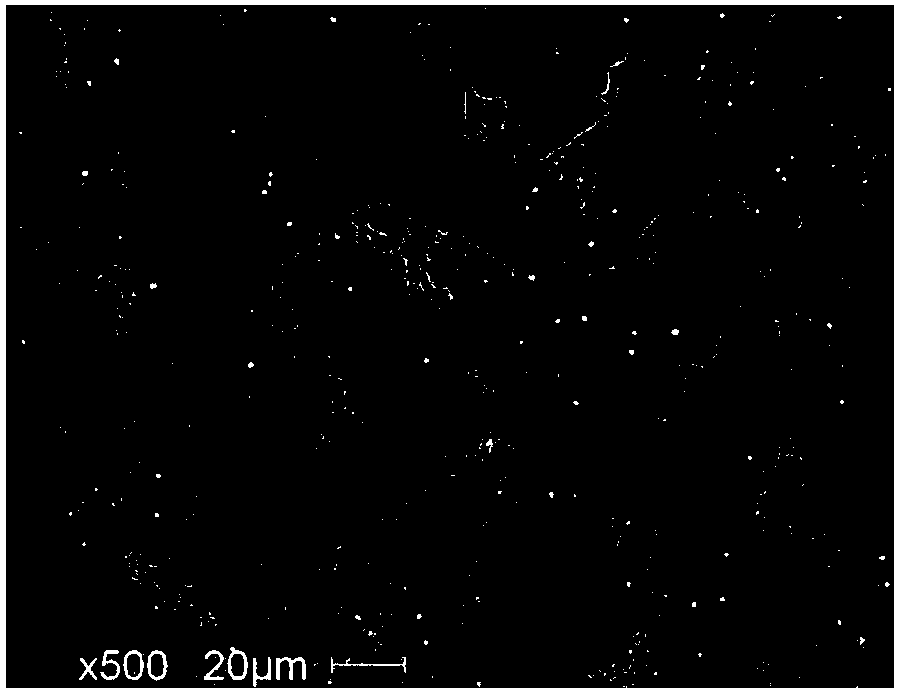

Image

Examples

Embodiment 1

[0040] The preparation formula is La 5 Mg 85 Al 10 A high-capacity lightweight graphene-catalyzed rare-earth magnesium-aluminum-based hydrogen storage material, in which GR accounts for 5% of the final hydrogen storage material based on mass percentage content. The preparation method steps are as follows:

[0041] a. Weighing: according to the chemical formula La 5 Mg 85 Al 10 Weigh the required raw materials. Weigh 452g of rare earth lanthanum ingots, 1380g of metal magnesium ingots and 168g of metal aluminum ingots with a purity greater than 99.5%. Among them, metal magnesium and lanthanum increase the burning loss by 8% and 5% respectively on the basis of the theoretical ratio;

[0042] b. Melting: Put the weighed raw materials (total 2kg) in the medium frequency induction melting furnace. Vacuum the furnace to 10 - 3 After Pa, inject 0.04MPa helium gas for protection. After preheating the crucible for 30 minutes, adjust the power to 5-20kW until the alloy is comp...

Embodiment 2

[0048] The preparation formula is Ce 5 Mg 85 Al 10 A high-capacity lightweight graphene-catalyzed rare-earth magnesium-aluminum-based hydrogen storage material, in which GR accounts for 5% of the final hydrogen storage material based on mass percentage content. The preparation method steps are as follows:

[0049] a. Weighing: Composition Ce according to chemical formula 5 Mg 85 Al 10 Weigh the required raw materials. Weigh 455g of rare earth cerium ingots, 1380g of metal magnesium ingots and 165g of metal aluminum ingots with a purity greater than 99.5%. Among them, metal magnesium and cerium increase the burning loss by 8% and 5% respectively on the basis of the theoretical ratio;

[0050] b. Melting: Put the weighed raw materials (total 2kg) in the medium frequency induction melting furnace. Vacuum the furnace to 10 - 3 After Pa, inject 0.04MPa helium gas for protection. After preheating the crucible for 30 minutes, adjust the power to 5-20kW until the alloy is co...

Embodiment 3

[0056] The preparation formula is Pr 5 Mg 85 Al 10 A high-capacity lightweight graphene-catalyzed rare-earth magnesium-aluminum-based hydrogen storage material, in which GR accounts for 5% of the final hydrogen storage material based on mass percentage content. The preparation method steps are as follows:

[0057] a. Weighing: Composition of Pr according to chemical formula 5 Mg 85 Al 10 Weigh the required raw materials. Weigh 459g of rare earth praseodymium ingots, 1380g of metal magnesium ingots and 161g of metal aluminum ingots with a purity greater than 99.5%. Among them, metal magnesium and praseodymium increase the burning loss by 8% and 5% respectively on the basis of the theoretical ratio;

[0058] b. Melting: Put the weighed raw materials (total 2kg) in the medium frequency induction melting furnace. Vacuum the furnace to 10 - 3 After Pa, inject 0.04MPa helium gas for protection. After preheating the crucible for 30 minutes, adjust the power to 5-20kW until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com