Arsenic fixing and copper extracting method of high-arsenic copper sulphide ore

A technology of copper sulfide ore and pulp, applied in the direction of improving process efficiency, etc., can solve the problems of difficult storage and sales of arsenic products, low recovery rate, strict environmental protection standards, etc., to solve the problem of insoluble copper precipitation, improve recovery rate, The effect of efficient and environmentally friendly utilization

Inactive Publication Date: 2018-06-29

INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

View PDF5 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among them, the pyrotechnic process has mature technology, good effect and comprehensive recovery of multiple elements, but it suffers from increasingly stringent environmental protection standards, high gas recovery costs, and difficulty in storing and selling arsenic products; the bio-oxidation leaching process is low in cost and environmentally friendly (no smoke emission), arsenic curing effect is widely concerned, but there are problems such as slow reaction speed, low recovery rate and poor adaptability; acid / alkali leaching process is environmentally friendly (no smoke emission), Arsenic has obvious advantages such as good curing effect and fast reaction speed, and will receive more and more attention with the improvement of environmental protection standards

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

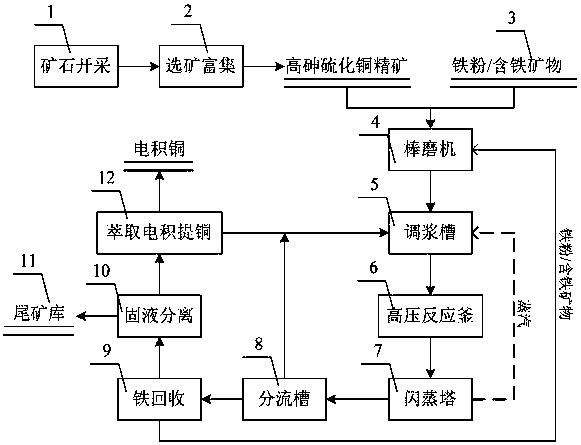

[0033] Such as figure 1 As shown, the technical process of the method for arsenic fixation and copper extraction of a high-arsenic copper sulfide ore involved in the present invention. The technical solution of the present invention will be described in further detail below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

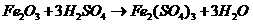

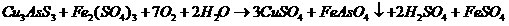

The invention discloses an arsenic fixing and copper extracting method of high-arsenic copper sulphide ore, which is used for fixing arsenic and extracting copper from the high-arsenic copper sulphideore, especially the copper ore using tennatite and enargite as main bodies. According to the arsenic fixing and copper extracting method, the dissolution behavior of the tennatite and the enargite ina sulfuric acid system is fully used, and harmful arsenic is easy to oxidize in the conditions of high temperature and oxygen enrichment so as to generate iron arsenate with stable chemical characteristics; the arsenic fixing and copper extracting method is developed on the basis of a hot pressing oxidation technique and a Fe / As matching principle; and a closed-loop water circulation wet processis adopted by the method, no waste water and exhaust gas are discharged, As in raw materials exists in tailings in the arsenide-iron arsenate state with the optimal chemical stability, and other Fe and S which has potential impact on the environment exists in the tailings in the stable state of calcium sulfate, ferric sulphate and the like. To sum up, the application field of the hot pressing oxidation technique is extended by the method, and a novel process with cleanness and environmental friendliness is provided for the utilization of resources of the high-arsenic copper sulphide ore whichis difficult to process.

Description

technical field [0001] The invention relates to an arsenic-fixing and copper-extracting technology in the mining industry, specifically, a method for arsenic-fixing and copper-extracting a high-arsenic copper sulfide ore whose main copper ore is arsenic tetrahedrite or arsenic copper ore. Background technique [0002] Copper is a pillar raw material for national economic construction. With the rapid development of national economy, the demand for copper is also increasing. With the continuous mining of copper mines and the depletion of disposable copper resources, more and more attention has been paid to the development of arsenic-containing copper sulfide resources, which account for 15% of the world's copper resources. If traditional pyrometallurgy or chemical leaching processes are used to treat such copper mines, a large amount of arsenic-containing wastes will be produced. If no reasonable recovery or elimination method is proposed, it will bring a series of environment...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22B15/00C22B3/44

CPCC22B3/44C22B15/0093Y02P10/20

Inventor 舒荣波程蓉黄云阶徐明陈晓青闫武

Owner INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com