Biodegradable poly-terephthalic acid type foaming material and preparation method thereof

A technology of polyterephthalic acid and foaming materials, applied in the field of degradable polyterephthalic acid foaming materials and its preparation, can solve the problems of less than 20 minutes of service life, non-durability, instability, etc., and achieve Continuously controllable and stable foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

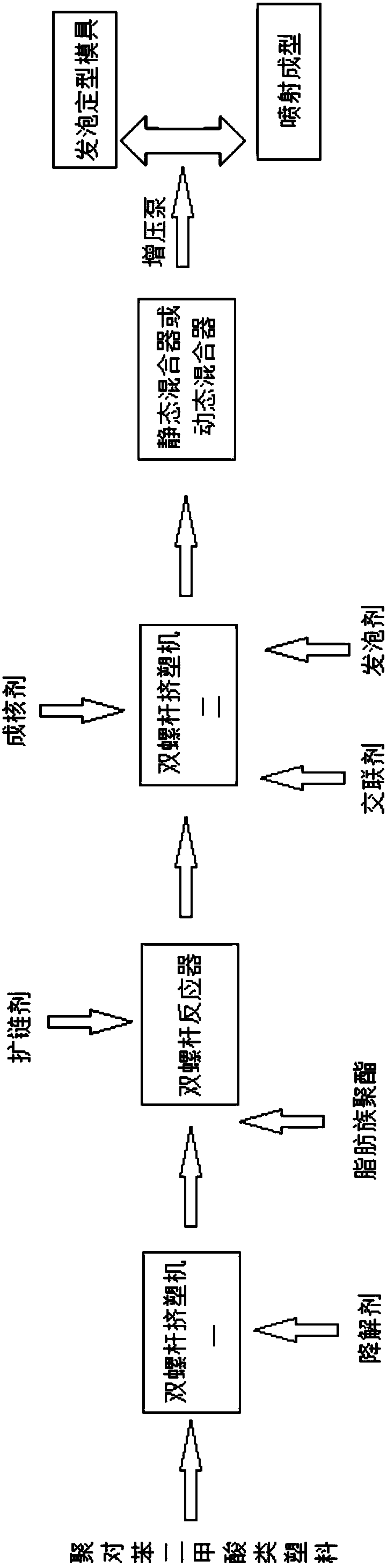

[0052] A preparation method of degradable poly terephthalic foam material, comprising the following steps:

[0053] (1): Put 0.1-100 parts of polyterephthalic acid plastics and 0-10 parts of degradation agent into the screw extruder 1, shear and melt to form a fluid hot melt 1, at this time, use the screw High-temperature and high-speed shearing, together with degradation agents such as short-chain alcohols, partially degrades polyterephthalic acid plastics into molecular fragments, and makes molecular fragments capped by functional groups such as hydroxyl groups; this step is to promote For the degradation reaction, metal catalysts, such as organotin / organozinc / organosilver, can be added.

[0054] (2): Pump the hot melt into the screw reactor, and then add 0.1-10 parts of chain extender (diisocyanate-terminated long-chain polyurethane prepolymer, which can be toluene 2,4 diisocyanate TDI, diphenyl methane diisocyanate MDI, isophorone diisocyanate IPDI or hexamethylene diisoc...

Embodiment 1

[0075] A kind of preparation method of degradable polyethylene terephthalic foam material, see figure 1 shown, including the following steps:

[0076] (1): Put 100 parts of polyterephthalic acid plastics (this embodiment uses PET) and 5 parts of degradation agent (this embodiment uses 1,4-butanediol) into screw extruder one, the operating temperature At 230°C, the shear melting forms a fluid hot melt. At this time, the high-temperature and high-speed shearing of the screw is used, and the short-chain alcohol and other degradation agents are used to partially degrade the polyterephthalic acid plastics into pieces. Molecular fragments, and the molecular fragments are capped by functional groups such as hydroxyl groups;

[0077] (2): The hot melt is pumped into the screw reactor, and then 5 parts of chain extenders are added (this embodiment uses diisocyanate-terminated long-chain polyurethane prepolymers, which are specifically composed of dicyclohexylmethane diisocyanate HMDI ...

Embodiment 2

[0081] Different from Example 1, this embodiment is further in the screw reactor of step (2) when adding the hot melt 1, and also adding 97 parts of aliphatic polyester (this embodiment adopts adipate adipate) Alcohol ester) is sheared and melted into hot melt two in screw extruder three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com