Oil composition and cocoa butter substitute food containing same

A technology of oil composition and cocoa butter substitute, which is applied in cocoa, edible oil/fat, food science, etc., can solve the problems of increasing cost and process complexity, not using cocoa butter substitute, etc., and achieves superior gas-holding performance and simplified The effect of short operation and passing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

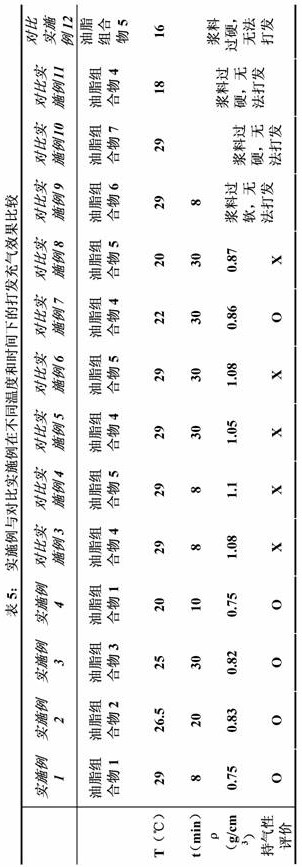

Examples

Embodiment

[0090] Example:

[0091] Vegetable oils and emulsifiers used in the present invention are from Kerry Special Oils (Shanghai) Co., Ltd.

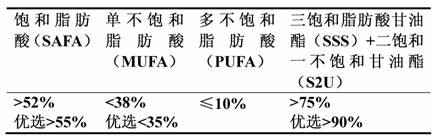

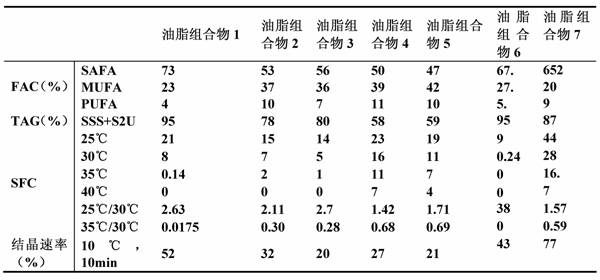

[0092] In the present invention, the detection method adopted is as follows.

[0093] Melting point detection: according to ISO 6321:2002 Determination of melting point (slip point) of animal and vegetable fats and oils.

[0094] Iodine value (IV) test: Determination according to GB / T 5532 Animal and vegetable oil iodine value.

[0095] Fatty acid composition (FAC) detection: Determination according to GB / T 17376 Preparation of fatty acid methyl esters of animal and vegetable oils and GB / T 17377 Gas chromatography analysis method of fatty acid methyl esters of animal and vegetable oils.

[0096] Triacylglycerol (TAG) detection: determined according to AOCS Ce 5-86, AOCS Ce 5-86 (1997) Triglycerides by gas chromatography.

[0097] Solid fat content (SFC) detection: Put the sample into a special glass sample tube for pulse nuclear magnetic r...

preparation example 1

[0104] Sample preparation: 300g palm kernel oil (PKOL) (iodine value IV=20~22 gI 2 / 100g) and 200g palm stearin (ST) (iodine value IV=35~37 gI 2 / 100g, melting point = 52.3℃) mixed, palm kernel liquid oil: palm stearin ratio 3:2, vacuum dry the mixed oil raw materials (vacuum stirring, heating to 105℃, keep for 30min~1h), then add 5g, 1% catalyst sodium methoxide, react at 100°C for 30min; then cool down to 70°C and break the vacuum, then add 1% citric acid aqueous solution, stir for 30min, terminate the reaction, wash the reactant with water until the pH is 7, and centrifuge to obtain transesterify the oil, and then refine the obtained transesterified oil: heat the transesterified oil to 105°C in vacuum, keep it for 30 minutes, dehydrate and dry; then add 2% activated clay, keep it at 110°C for 30 minutes for decolorization, add diatom Soil filter aid to obtain transesterified oil. Finally, vacuumize at 240°C and deodorize the transesterified oil to free fatty acid 2 / 100g,...

preparation example 2

[0106] Mix 100g of coconut oil (CNO) and 400g of palm olein (OL), the ratio of coconut oil:palm olein is 1:4, and carry out chemical transesterification and refining according to the method of Preparation Example 1 above. Get IV=46 gI 2 / 100g, oil and fat composition 2 with a melting point of about 35°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com