High molecular weight polycarbosilane and preparation method thereof

A technology of polycarbosilane and high molecular weight, which is applied in the field of high molecular weight polycarbosilane and its preparation, can solve the problems of low content of reactive groups, high content of free carbon, high oxygen content of SiC fibers, etc., and achieve high free radical concentration, The product has a large molecular weight and is easy to synthesize in batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

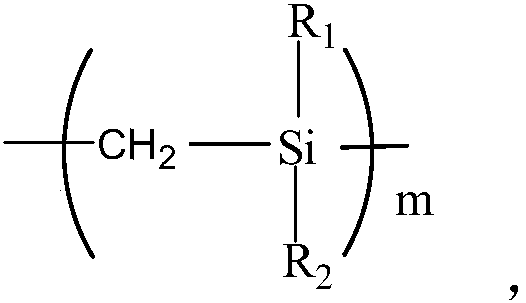

[0026] Embodiment 1 proposes a kind of high molecular weight polycarbosilane, and the molecular structure of described polycarbosilane is:

[0027]

[0028] Among them, R 1 for H, R 2 for

[0029] m is a positive integer, n, p, q are positive integers <5.

[0030] The preparation method of the high molecular weight polycarbosilane of embodiment 1 comprises the steps:

[0031] Polydimethylsilane pretreatment: place polydimethylsilane in a distillation device, distill under a high-purity nitrogen atmosphere with a flow rate of 80 mL / min and collect fractions at 105°C.

[0032] Polydimethylsilane cracking reaction: the pretreated polydimethylsilane and reducing metal powder are successively placed in an autoclave, and the reducing metal powder is evenly distributed on the surface of the polydimethylsilane , and then replaced by nitrogen for 3 times, and pre-introduced 0.5MPa nitrogen with a flow rate of 120mL / min, then raised the temperature to 320°C at a heating rate of...

Embodiment 2

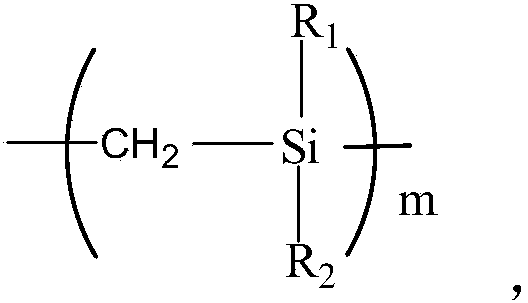

[0036] Embodiment 2 proposes a kind of high molecular weight polycarbosilane, and the molecular structure of described polycarbosilane is:

[0037]

[0038] Among them, R 1 for R 2 for

[0039] m is a positive integer, n, p, q are positive integers <5.

[0040] The preparation method of the high molecular weight polycarbosilane of embodiment 2 comprises the steps:

[0041] Polydimethylsilane pretreatment: place polydimethylsilane in a distillation device, distill under a high-purity nitrogen atmosphere with a flow rate of 120mL / min and collect fractions at 100°C.

[0042] Polydimethylsilane cracking reaction: the pretreated polydimethylsilane and reducing metal powder are successively placed in an autoclave, and the reducing metal powder is evenly distributed on the surface of the polydimethylsilane , and then pass nitrogen replacement 5 times, and pre-feed 2MPa nitrogen at a flow rate of 80mL / min, then raise the temperature to 360°C at a heating rate of 295°C / h and k...

Embodiment 3

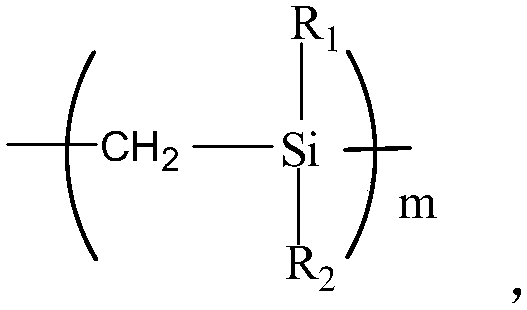

[0046] Embodiment 3 proposes a kind of high molecular weight polycarbosilane, the molecular structure of described polycarbosilane is:

[0047]

[0048] Among them, R 2 for H, R 1 for

[0049] m is a positive integer, n, p, q are positive integers <5.

[0050] The preparation method of the high molecular weight polycarbosilane of embodiment 3 comprises the steps:

[0051] Polydimethylsilane pretreatment: place polydimethylsilane in a distillation device, distill under a high-purity nitrogen atmosphere with a flow rate of 100 mL / min and collect fractions at 103°C.

[0052] Polydimethylsilane cracking reaction: the pretreated polydimethylsilane and reducing metal powder are successively placed in an autoclave, and the reducing metal powder is evenly distributed on the surface of the polydimethylsilane , and then replaced by nitrogen for 4 times, and pre-filled with 1.2MPa nitrogen at a flow rate of 100mL / min, then raised the temperature to 340°C at a heating rate of 215...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com