Preparation method and application of high-concentration free radical electrode

A free radical and high-concentration technology, applied in the field of organic pollutants, can solve the problems of electrode passivation and deactivation, low free radical concentration, slow degradation rate, etc., and achieve high free radical concentration, enhanced binding, and short treatment process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

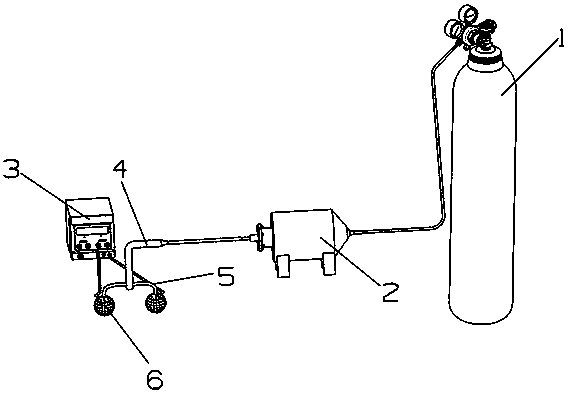

Image

Examples

Embodiment 1

[0030] Embodiment 1: The preparation method of this high-concentration free radical electrode material and the pretreatment of coking wastewater, the specific contents are as follows:

[0031] (1) The spherical hollow titanium substrate is subjected to roughening treatment. The roughening treatment is to immerse the spherical hollow titanium substrate in a sodium hydroxide solution with a concentration of 10% by mass, heat it in a water bath to 60°C, keep it for 2 hours, and take out the spherical hollow titanium substrate. , immersed in an oxalic acid solution with a mass percentage concentration of 10%, treated at 70°C for 2 hours, taken out and rinsed with double distilled water until the pH is neutral;

[0032] (2) Perform electroless plating on the roughened titanium substrate to form a tin-antimony oxide bottom layer on the surface of the titanium substrate. Electroless plating is to uniformly coat the tin-antimony oxide sol on the surface of the roughened titanium substr...

Embodiment 2

[0037] Embodiment 2: The preparation method of this high-concentration free radical electrode material and the treatment of high-concentration organic wastewater from farms, the specific contents are as follows:

[0038] (1) The spherical hollow titanium substrate is subjected to roughening treatment. The roughening treatment is to immerse the spherical hollow titanium substrate in a sodium hydroxide solution with a concentration of 10% by mass, heat it in a water bath to 70°C, keep it for 2 hours, and take out the spherical hollow titanium substrate. , immersed in an oxalic acid solution with a mass percentage concentration of 10%, treated at 80°C for 2 hours, taken out and rinsed with double distilled water until the pH is neutral;

[0039] (2) Perform electroless plating on the roughened titanium substrate to form a tin-antimony oxide bottom layer on the surface of the titanium substrate. Electroless plating is to uniformly coat the tin-antimony oxide sol on the surface of t...

Embodiment 3

[0044] Embodiment 3: The preparation method of this high-concentration free radical electrode material and improving the aerobic composting rate of livestock and poultry manure, the specific contents are as follows:

[0045] (1) The spherical hollow titanium substrate is subjected to roughening treatment. The roughening treatment is to immerse the spherical hollow titanium substrate in a sodium hydroxide solution with a concentration of 10% by mass, heat it in a water bath to 80°C, keep it for 2 hours, and take out the spherical hollow titanium substrate. , immersed in an oxalic acid solution with a mass percentage concentration of 10%, treated at 75°C for 2 hours, taken out and rinsed with double distilled water until the pH is neutral;

[0046] (2) Perform electroless plating on the roughened titanium substrate to form a tin-antimony oxide bottom layer on the surface of the titanium substrate. Electroless plating is to uniformly coat the tin-antimony oxide sol on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com