Preparation method and application of a high-concentration free radical electrode

A free radical, high concentration technology, applied in the field of organic pollutants, can solve the problems of low free radical concentration, electrode passivation inactivation, slow degradation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

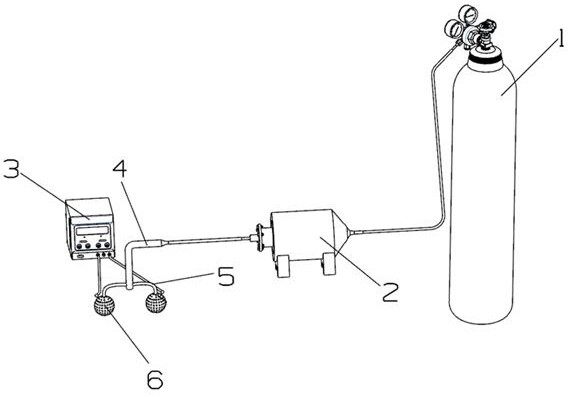

Image

Examples

Embodiment 1

[0030] Embodiment 1: The preparation method of this high-concentration free radical electrode material and the pretreatment of coking wastewater, the specific contents are as follows:

[0031] (1) The spherical hollow titanium substrate is subjected to roughening treatment. The roughening treatment is to immerse the spherical hollow titanium substrate in a sodium hydroxide solution with a concentration of 10% by mass, heat it in a water bath to 60°C, keep it for 2 hours, and take out the spherical hollow titanium substrate. , immersed in an oxalic acid solution with a mass percentage concentration of 10%, treated at 70°C for 2 hours, taken out and rinsed with double distilled water until the pH is neutral;

[0032] (2) Perform electroless plating on the roughened titanium substrate to form a tin-antimony oxide bottom layer on the surface of the titanium substrate. Electroless plating is to uniformly coat the tin-antimony oxide sol on the surface of the roughened titanium substr...

Embodiment 2

[0037] Embodiment 2: The preparation method of this high-concentration free radical electrode material and the treatment of high-concentration organic wastewater from farms, the specific contents are as follows:

[0038] (1) The spherical hollow titanium substrate is subjected to roughening treatment. The roughening treatment is to immerse the spherical hollow titanium substrate in a sodium hydroxide solution with a concentration of 10% by mass, heat it in a water bath to 70°C, keep it for 2 hours, and take out the spherical hollow titanium substrate. , immersed in an oxalic acid solution with a mass percentage concentration of 10%, treated at 80°C for 2 hours, taken out and rinsed with double distilled water until the pH is neutral;

[0039] (2) Perform electroless plating on the roughened titanium substrate to form a tin-antimony oxide bottom layer on the surface of the titanium substrate. Electroless plating is to uniformly coat the tin-antimony oxide sol on the surface of t...

Embodiment 3

[0044] Embodiment 3: The preparation method of this high-concentration free radical electrode material and improving the aerobic composting rate of livestock and poultry manure, the specific contents are as follows:

[0045] (1) The spherical hollow titanium substrate is subjected to roughening treatment. The roughening treatment is to immerse the spherical hollow titanium substrate in a sodium hydroxide solution with a concentration of 10% by mass, heat it in a water bath to 80°C, keep it for 2 hours, and take out the spherical hollow titanium substrate. , immersed in an oxalic acid solution with a mass percentage concentration of 10%, treated at 75°C for 2 hours, taken out and rinsed with double distilled water until the pH is neutral;

[0046] (2) Perform electroless plating on the roughened titanium substrate to form a tin-antimony oxide bottom layer on the surface of the titanium substrate. Electroless plating is to uniformly coat the tin-antimony oxide sol on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com