Low-expansion anti-sticking antibacterial ceramic pot and manufacturing process thereof

A ceramic pot, low expansion technology, applied in clay products, other household utensils, applications, etc., can solve the problems of inconvenient cleaning of food residue, bad for human health, cracks in ceramic pots, etc., to improve acid and alkali corrosion resistance and thermal expansion performance , reduce the thermal expansion rate, reduce the effect of firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

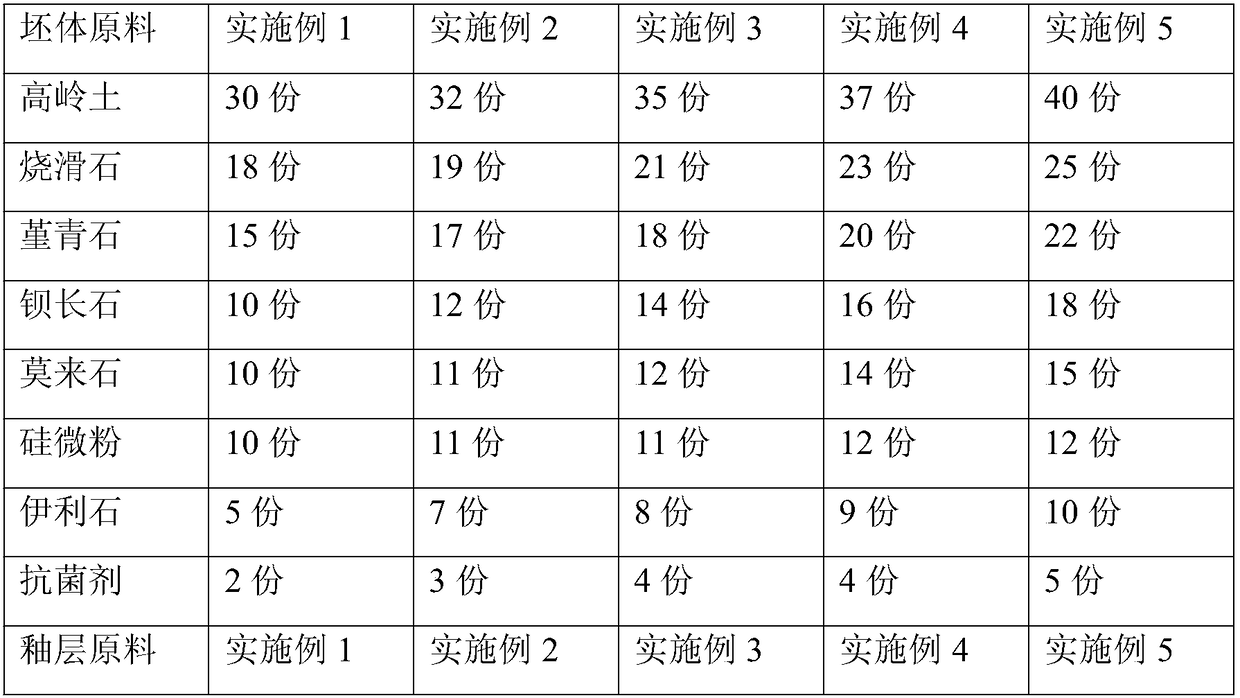

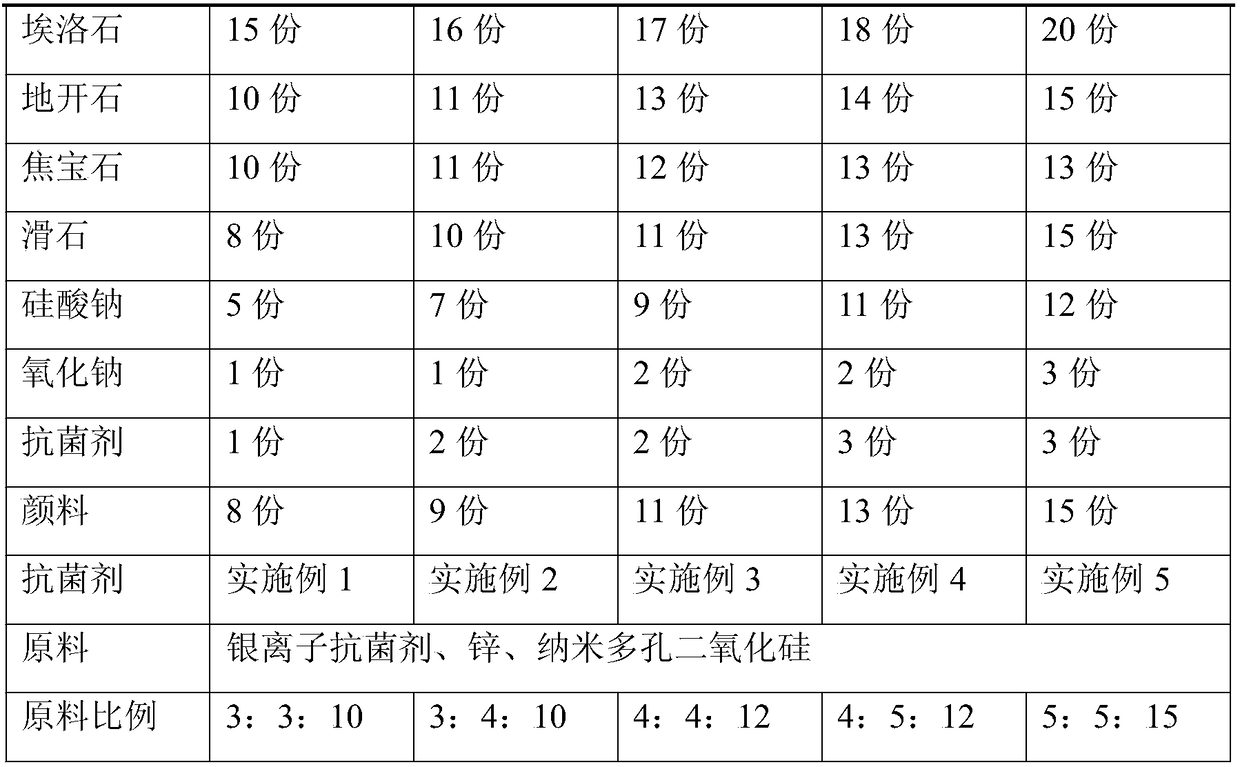

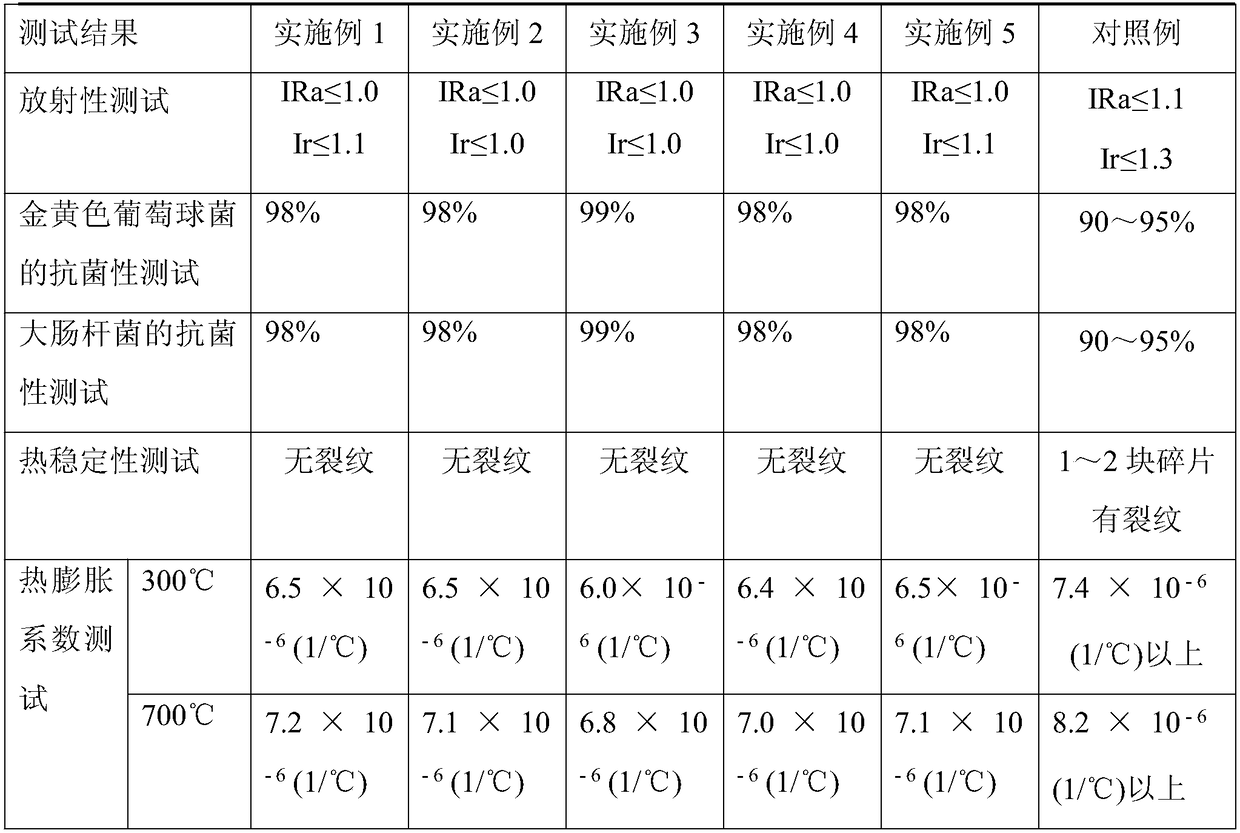

Embodiment 1

[0022] This embodiment provides a low-expansion anti-stick antibacterial ceramic pot and its manufacturing process, including a green body and a glaze layer. The green body includes the following raw materials in parts by weight: 30 parts of kaolin, 18 parts of calcined talc, 15 parts of cordierite, 10 parts of barium feldspar, 10 parts of mullite, 10 parts of silicon micropowder, 5 parts of illite, 2 parts of antibacterial agent; The glaze layer includes the following raw materials in parts by weight: 15 parts of halloysite, 10 parts of dickite, 10 parts of burnt gems, 8 parts of talc, 5 parts of sodium silicate, 1 part of sodium oxide, 1 part of antibacterial agent, and 8 parts of pigment, wherein the antibacterial agent is composed of silver ion antibacterial agent with a weight ratio of 3:3:10, It is made by mixing zinc and nanoporous silicon dioxide.

[0023] This embodiment also provides a manufacturing process for a low-expansion anti-stick antibacterial ceramic pot, co...

Embodiment 2

[0029] This embodiment provides a low-expansion anti-stick antibacterial ceramic pot and its manufacturing process, including a green body and a glaze layer. The green body includes the following raw materials in parts by weight: 32 parts of kaolin, 19 parts of calcined talc, 17 parts of cordierite, 12 parts of feldspar, 11 parts of mullite, 11 parts of silicon micropowder, 7 parts of illite, 3 parts of antibacterial agent; The glaze layer includes the following raw materials in parts by weight: 16 parts of halloysite, 11 parts of dickite, 11 parts of burnt gemstones, 10 parts of talc, 7 parts of sodium silicate, 1 part of sodium oxide, 2 parts of antibacterial agents, and 9 parts of pigments, wherein the antibacterial agent is composed of silver ion antibacterial agents with a weight ratio of 3:4:10, It is made by mixing zinc and nanoporous silicon dioxide.

[0030] This embodiment also provides a manufacturing process for a low-expansion anti-stick antibacterial ceramic pot,...

Embodiment 3

[0036] This embodiment provides a low-expansion anti-stick antibacterial ceramic pot and its manufacturing process, including a green body and a glaze layer. The green body includes the following raw materials in parts by weight: 35 parts of kaolin, 21 parts of burnt talc, 18 parts of cordierite, 14 parts of feldspar, 12 parts of mullite, 11 parts of micro-silicon powder, 8 parts of illite, 4 parts of antibacterial agent; The glaze layer includes the following raw materials in parts by weight: 17 parts of halloysite, 13 parts of dickite, 12 parts of burnt gemstones, 11 parts of talc, 9 parts of sodium silicate, 2 parts of sodium oxide, 2 parts of antibacterial agents, and 11 parts of pigments, wherein the antibacterial agent is a silver ion antibacterial agent with a weight ratio of 4:4:12, It is made by mixing zinc and nanoporous silicon dioxide.

[0037] This embodiment also provides a manufacturing process for a low-expansion anti-stick antibacterial ceramic pot, comprising...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com