A repair material for extremely cold pavement and its preparation method and application

A repairing material and an extremely cold technology, which are applied to the field of repairing materials for extremely cold pavements and their preparation, can solve the problems that the materials cannot be used for repairing in extremely cold areas, the cement concrete adhesion is low, and the construction time is long, so as to shorten the open traffic time. , high fluidity, fast and effective repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

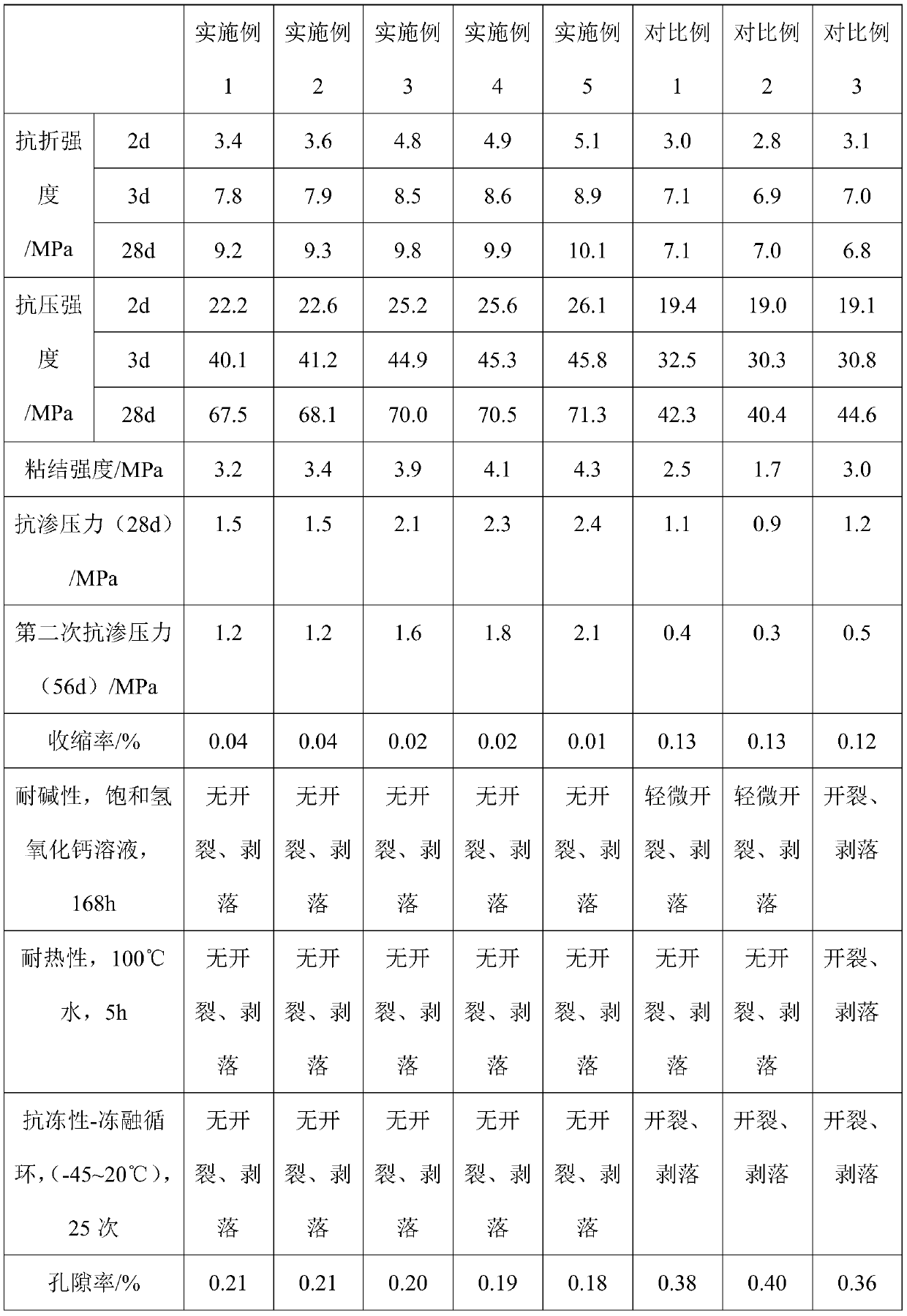

Examples

Embodiment 1

[0018] In an embodiment of the present invention, a repairing material for extremely cold road surfaces comprises the following raw materials: 60 kg of Portland cement, 32 kg of fine sand, 11 kg of sodium gluconate, 18 kg of diethylenetriamine, and 23 kg of polyketone resin.

[0019] Mix diethylenetriamine with 3.5 times the mass of ethanol to prepare a diethylenetriamine solution for later use. Heat the polyketone resin to 65°C, heat and stir at this temperature for 30 minutes, then raise the temperature to 78°C, add diethylenetriamine solution, and heat and stir at 78°C for 0.7h to prepare a mixture. Mix Portland cement, fine sand, and sodium gluconate evenly, then add the mixture, and stir for 1.1 hours to obtain the repair material.

Embodiment 2

[0021] In an embodiment of the present invention, a repairing material for extremely cold road surfaces comprises the following raw materials: 70 kg of Portland cement, 40 kg of fine sand, 19 kg of sodium gluconate, 26 kg of diethylenetriamine, and 31 kg of polyketone resin.

[0022] Diethylenetriamine is mixed with ethanol whose mass is 4 times that of it to prepare a diethylenetriamine solution for future use. Heat the polyketone resin to 70°C, heat and stir at this temperature for 35 minutes, then raise the temperature to 78°C, add diethylenetriamine solution, and heat and stir at 78°C for 0.8h to prepare a mixture. Mix Portland cement, fine sand, and sodium gluconate evenly, then add the mixture, and stir for 1.2 hours to obtain the repair material.

Embodiment 3

[0024] In an embodiment of the present invention, a repairing material for extremely cold road surfaces comprises the following raw materials: 62kg of Portland cement, 34kg of fine sand, 13kg of sodium gluconate, 20kg of diethylenetriamine, and 25kg of polyketone resin.

[0025] Diethylenetriamine is mixed with ethanol whose mass is 4 times that of it to prepare a diethylenetriamine solution for future use. Heat the polyketone resin to 68°C, heat and stir at this temperature for 35 minutes, then raise the temperature to 78°C, add diethylenetriamine solution, and heat and stir at 78°C for 0.8h to prepare a mixture. Mix and stir Portland cement, fine sand, and sodium gluconate evenly, then add the mixture, and stir for 1.2 hours to obtain the repair material. The stirring temperature when adding the mixture is 64°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com