Reaction device suitable for preparing hydrogen fluoride from calcium fluoride

A reaction device, hydrogen fluoride technology, applied in the direction of fluorine/hydrogen fluoride, hydrogen fluoride, etc., can solve problems such as blockage of pipeline equipment, and achieve the effects of prolonging life, large heat transfer area, and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

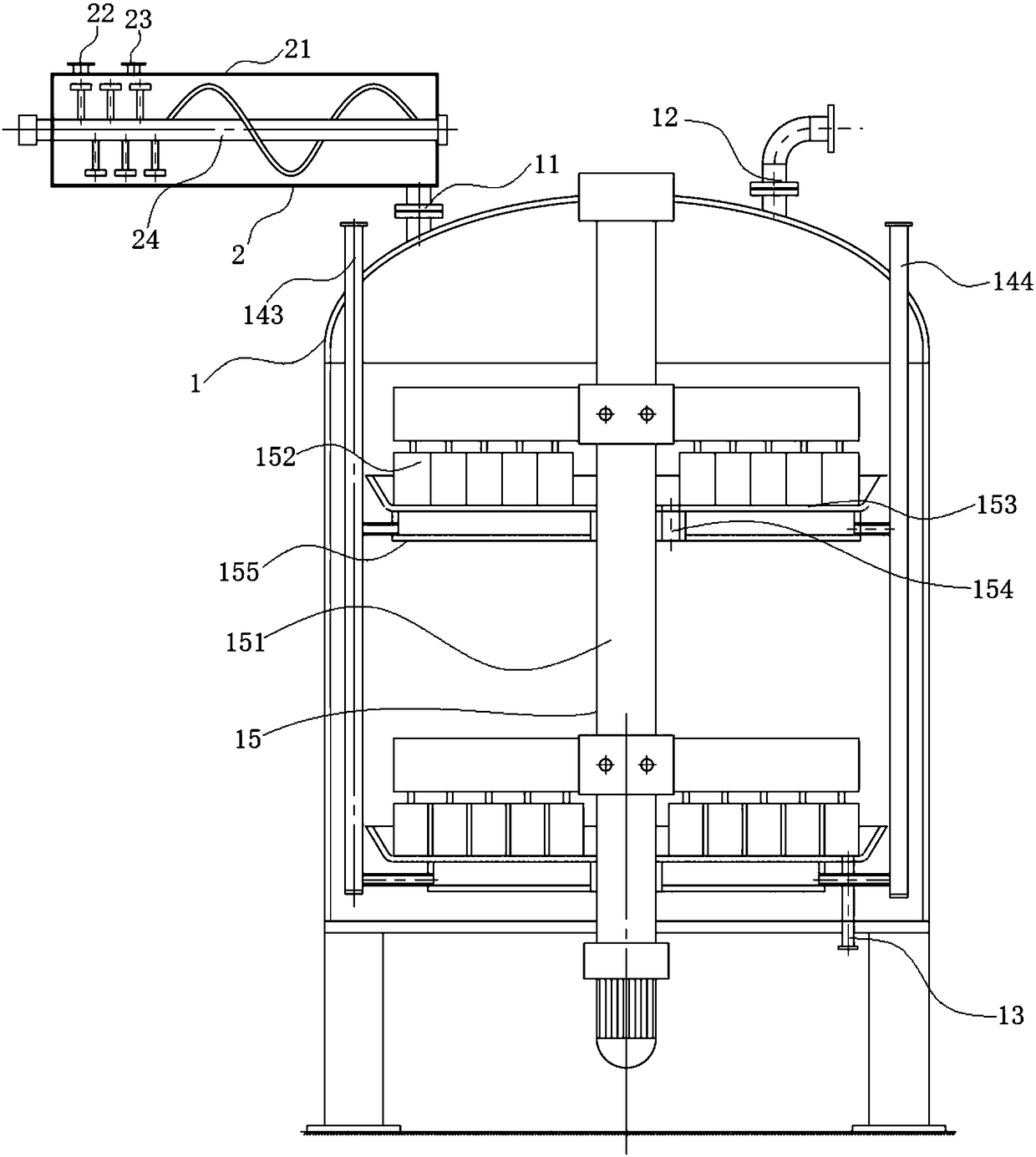

[0036] refer to figure 1 As shown, a reaction device suitable for preparing hydrogen fluoride from calcium fluoride includes a reactor 1 and a thermal energy device. Wherein the reactor 1 is a fully sealed vertical hollow structure, and the reactor in this embodiment is a vertical cylindrical structure. The top of the reactor 1 is provided with a first material inlet 11 and a gas outlet 12, and the bottom is provided with a material outlet 13, ie a calcium sulfate outlet. A stirrer 15 and a material receiving device 153 are also provided in the reactor 1 . The thermal energy device is used to provide thermal energy to the material receiving device 153 . The heat energy device comprises a heat medium input pipe 143 and a heat medium output pipe 144; the bottom surface of the material receiving device 153 is provided with a heat transfer layer 155 of a closed structure, and the heat medium input pipe 143 and the heat medium output pipe 144 communicate with the heat transfer la...

Embodiment 2

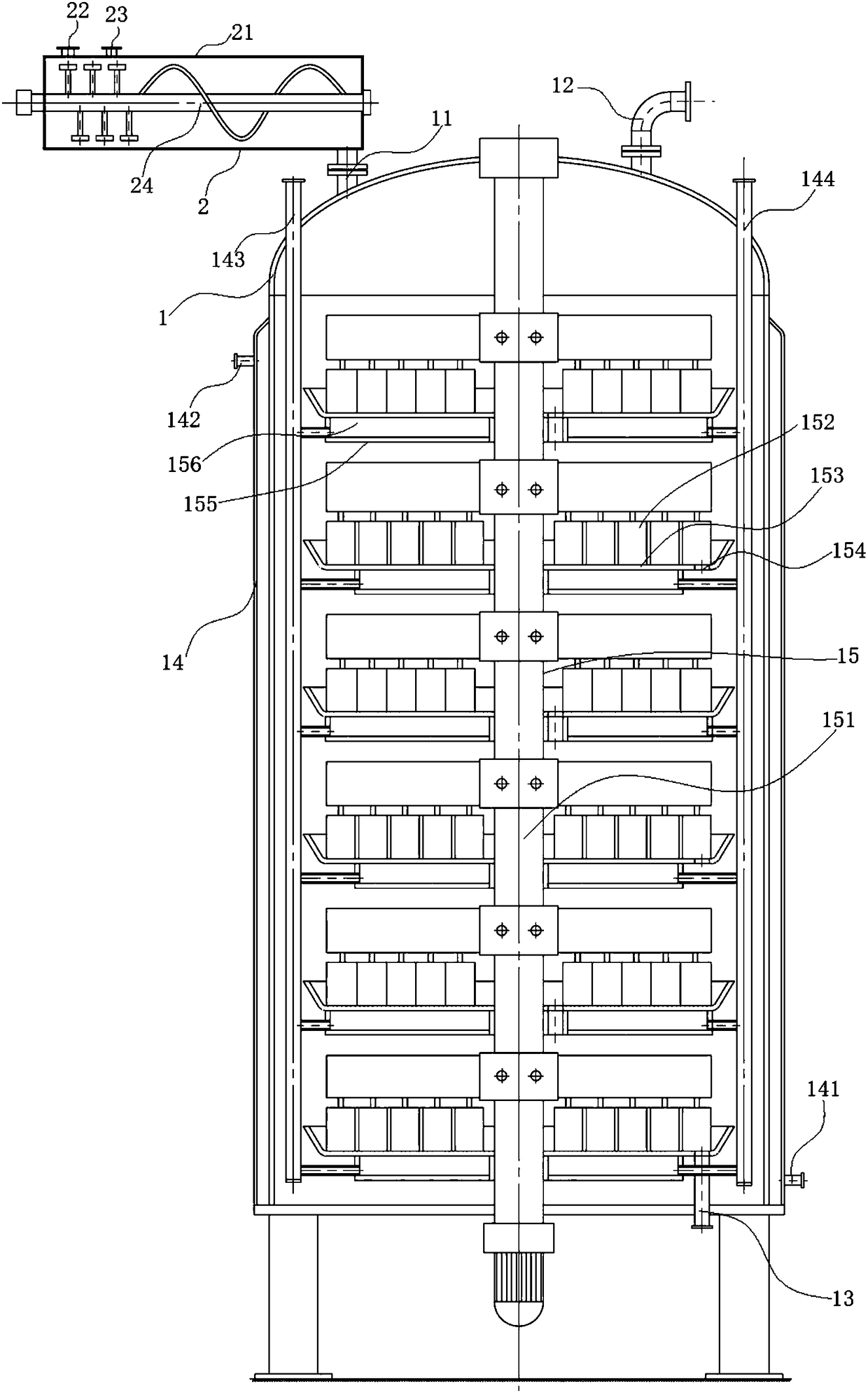

[0044] like figure 2 As shown, another solution of the present invention is that the present invention is provided with a jacket 14 outside the reactor 1, and the jacket 14 is provided with a heat medium second input port 141 and a heat medium second input port 141 for heat medium to flow in and out. Output port 142 . An insulating layer (not shown in the figure) is also provided on the outer side of the jacket 14 to reduce heat loss.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com