Spherical atomized aluminum-zinc amorphous alloy powder with high physical activity and preparation method thereof

An amorphous alloy and physical technology, which is applied in the field of high physical activity spherical atomized aluminum-zinc amorphous alloy powder and its preparation, can solve the problems of poor processability, low activity of aluminum particles, and difficulty in realizing the energy release rate of energetic materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

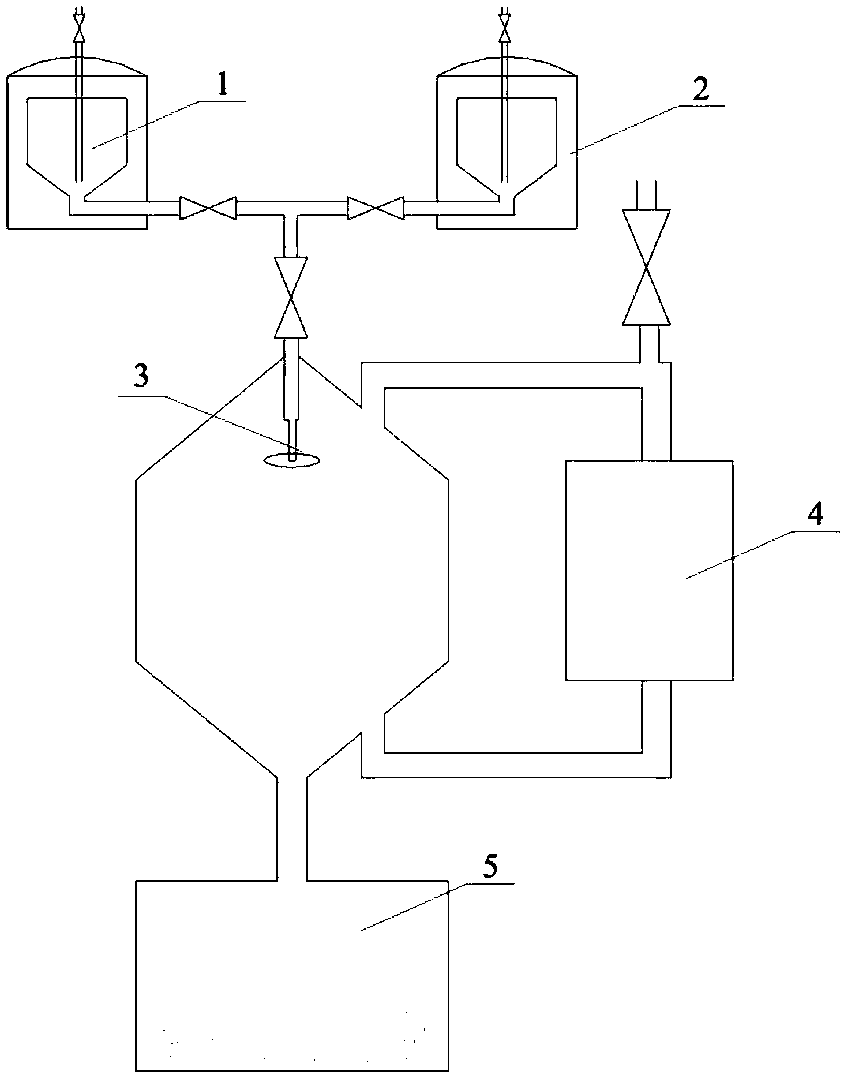

[0034] Prepare aluminum-zinc (90-10) alloy powder as follows:

[0035] (1) After putting the aluminum ingot and the zinc ingot into two pre-melting furnaces to evacuate respectively, use high-temperature inert gas to purge to remove the gas containing oxidizing atmosphere adsorbed on the surface;

[0036] (2) Use the intermediate frequency heating ring to heat the furnace body, the furnace body containing aluminum ingots is heated to 680 ° C, the furnace body containing zinc ingots is heated to 450 ° C, and protected by argon;

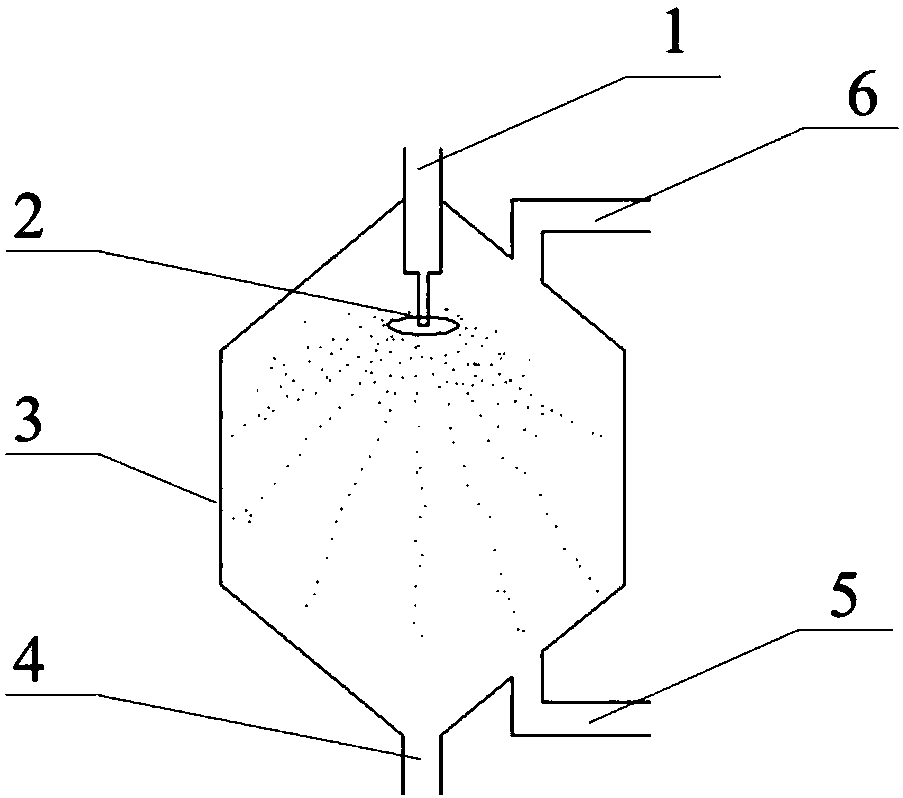

[0037] (3) Pass the liquid aluminum and liquid zinc into the disc atomizer in the atomization furnace, and realize the mass ratio of 90:10 by controlling the respective flow rates. Aluminum liquid and zinc liquid are mixed evenly on the disc atomizer, and are sprayed into small droplets after mixing. The frequency of the atomizer is controlled at 55Hz, and the size of the metal droplets is controlled by controlling the centrifuge speed and other parame...

Embodiment 2

[0041] Prepare aluminum-zinc (80-20) alloy powder as follows:

[0042] (1) After putting the aluminum ingot and the zinc ingot into two pre-melting furnaces to evacuate respectively, use high-temperature inert gas to purge to remove the gas containing oxidizing atmosphere adsorbed on the surface;

[0043](2) Use the intermediate frequency heating ring to heat the furnace body, the furnace body containing aluminum ingots is heated to 680 ° C, the furnace body containing zinc ingots is heated to 450 ° C, and protected by argon;

[0044] (3) Pass the liquid aluminum and liquid zinc into the disc atomizer in the atomization furnace, and realize the mass ratio of 80:20 by controlling the respective flow rates. Aluminum liquid and zinc liquid are mixed evenly on the disc atomizer, and are sprayed into small droplets after mixing. The frequency of the atomizer is controlled at 55Hz, and the size of the metal droplets is controlled by controlling the centrifuge speed and other paramet...

Embodiment 3

[0048] Prepare aluminum-zinc (70-30) alloy powder as follows:

[0049] (1) After putting the aluminum ingot and the zinc ingot into two pre-melting furnaces to evacuate respectively, use high-temperature inert gas to purge to remove the gas containing oxidizing atmosphere adsorbed on the surface;

[0050] (2) Use the intermediate frequency heating ring to heat the furnace body, the furnace body containing aluminum ingots is heated to 680 ° C, the furnace body containing zinc ingots is heated to 450 ° C, and protected by argon;

[0051] (3) Pass the liquid aluminum and liquid zinc into the disc atomizer in the atomization furnace, and realize the mass ratio of 70:30 by controlling the respective flow rates. Aluminum liquid and zinc liquid are mixed evenly on the disc atomizer, and are sprayed into small droplets after mixing. The frequency of the atomizer is controlled at 55Hz, and the size of the metal droplets is controlled by controlling the centrifuge speed and other parame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com