Method for analyzing sulfur-containing compound in liquefied gas

An analytical method and technology for sulfur compounds, which are applied in the direction of analyzing materials, analyzing by chemical reaction of materials, chemiluminescence/bioluminescence, etc., can solve problems such as inaccurate composition and content, and achieve simple and easy-to-operate methods and accurate measurement results. The effect of reliability, strong operability and application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

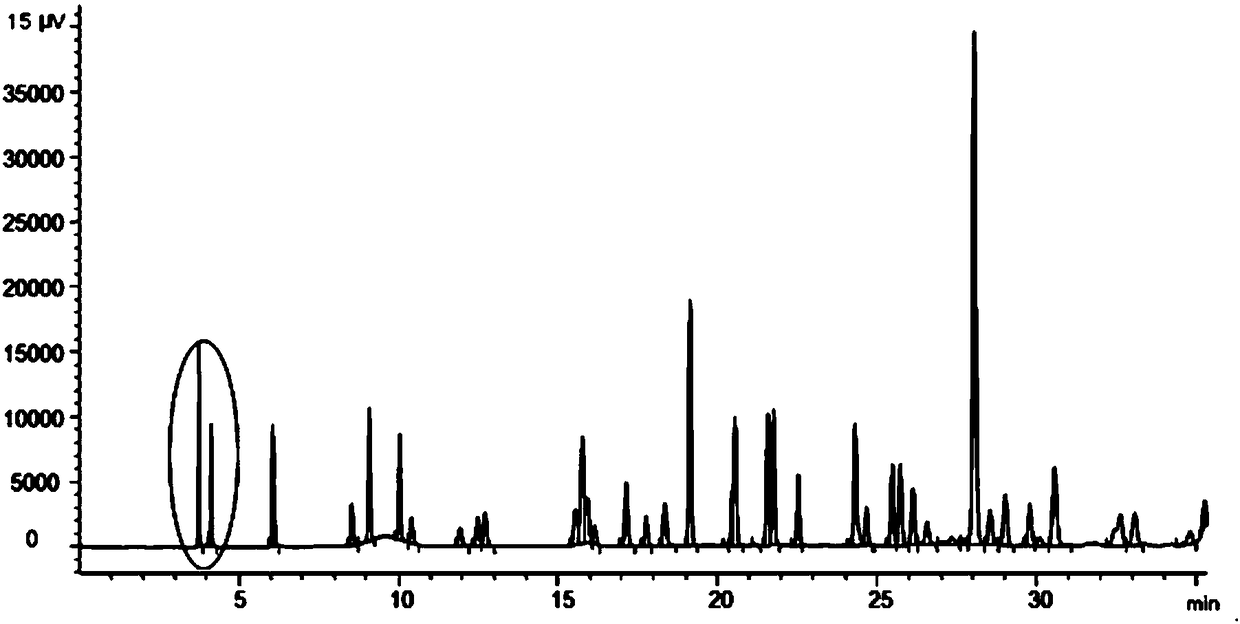

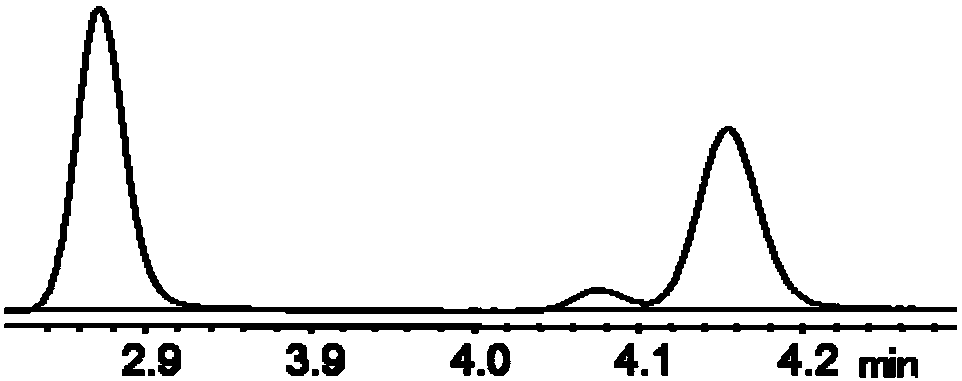

[0030] Prepare liquefied gas standards containing 35 sulfur compounds. A high-pressure liquid sampling valve was used to analyze the composition of the liquefied gas standard. The operating pressure of the high-pressure liquid sampling valve was 23 psi, and the valve capacity specification was 1 μL. GC-SCD operating conditions are: inlet temperature 250°C, split ratio 80:1; constant pressure operation, pressure 15psi; heating program: initial temperature is 50°C, after constant temperature for 4 minutes, the temperature is raised to 100°C at 10°C / min , after 6 minutes of constant temperature, the temperature was raised to 180°C at 15°C / min, and the temperature was kept constant for 10 minutes. Under these conditions, the chromatograms of each sulfur-containing compound are shown in figure 1 and figure 2 , the retention time of each compound is shown in Table 1.

[0031] This method can provide morphological information of 35 sulfur-containing compounds, and the resolution ...

Embodiment 2

[0035] Qingyang Petrochemical liquefied gas samples were collected according to the SH / T 0233 liquefied gas sampling method.

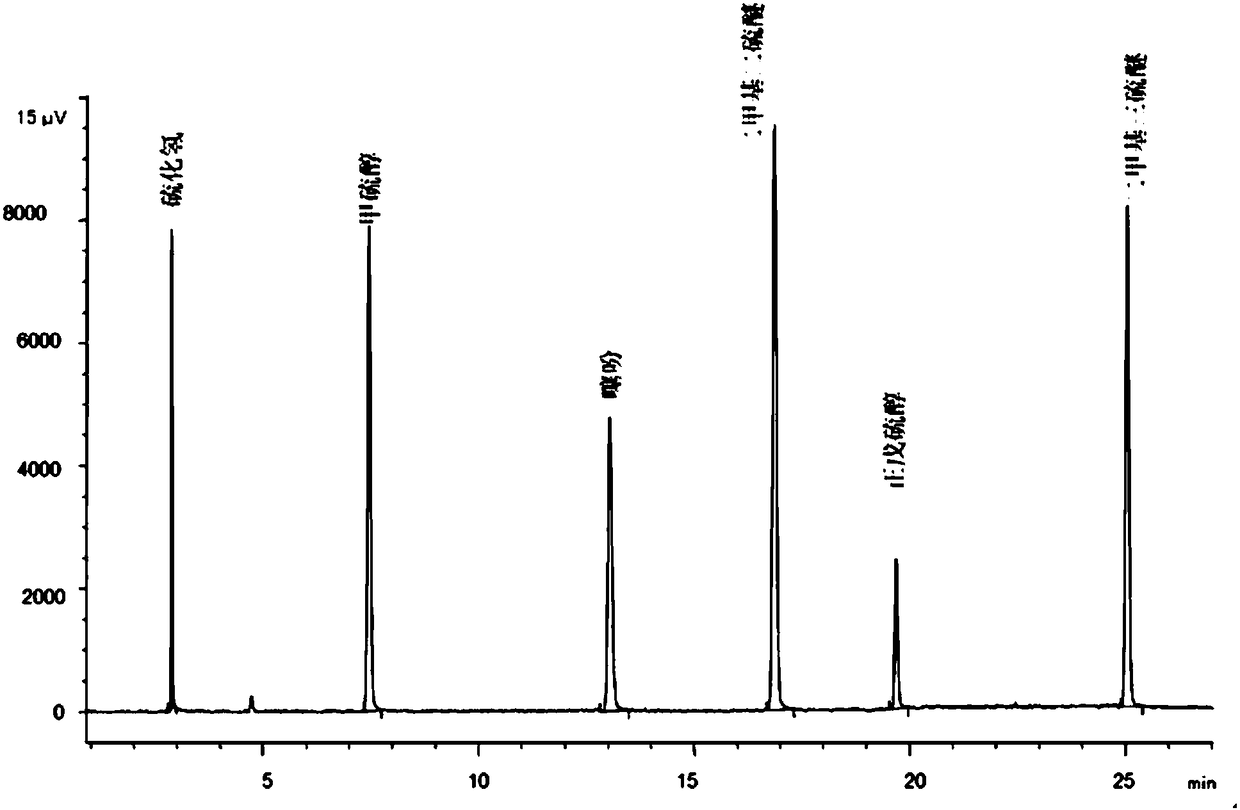

[0036] The qualitative analysis of the liquefied gas samples of Qingyang Petrochemical was carried out under the conditions described in Example 1: the composition of the liquefied gas samples was analyzed using a high-pressure liquid sampling valve, the operating pressure of the high-pressure liquid sampling valve was 23 psi, and the valve capacity specification was 1 μL. GC-SCD operating conditions are: inlet temperature 250°C, split ratio 80:1; constant pressure operation, pressure 15psi; heating program: initial temperature is 50°C, after constant temperature for 4 minutes, the temperature is raised to 100°C at 10°C / min , after 6 minutes of constant temperature, the temperature was raised to 180°C at 15°C / min, and the temperature was kept constant for 10 minutes. The obtained liquefied gas samples contained six sulfur-containing compounds, and the ...

Embodiment 3

[0041] Collect liquefied gas samples according to SH / T 0233 liquefied gas sampling method.

[0042] The process and conditions described in Example 1 were used to determine the composition of the liquefied gas, and the results are shown in Table 3.

[0043] Use a high-pressure liquid sampling valve to analyze the relative percentage of liquefied gas. The external standard sample of liquefied gas with a concentration of dimethyl sulfide (calculated based on sulfur content) is 51.67 μg / g. The analysis condition is that the operating pressure of the high-pressure liquid sampling valve is 18psi. , The valve capacity specification is 0.5μL. The operating conditions of GC-SCD are: the inlet temperature is 200°C, the split ratio is 30:1; the front pressure of the column is 20psi; °C, and then heated up to 170 °C at 20 °C / min. The content of sulfur compounds in liquefied gas is shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com