Metal organic gel-based Fe-N-C composite material and preparation method thereof

A composite material, metal-organic technology, applied in the field of nanomaterials, can solve the problems of high price, scarce reserves, CO poisoning, etc., and achieve the effects of high electrochemical stability, ingenious experimental design, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

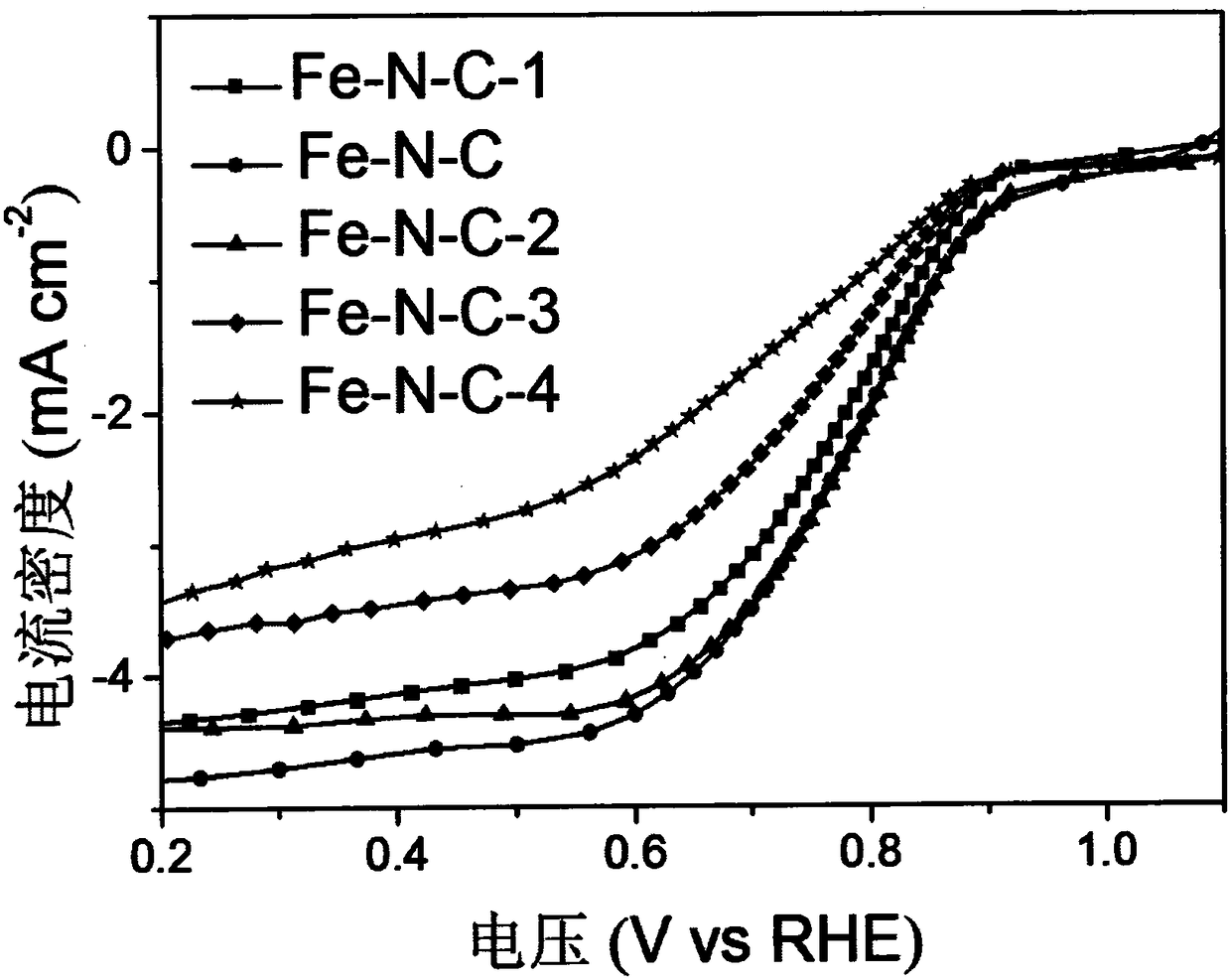

Embodiment 1

[0025] A kind of preparation method of Fe-N-C composite material based on metal organogel:

[0026] (1) Mix terephthalic acid and o-phenylenediamine, dissolve in N,N-2 methylformamide, the mass ratio of terephthalic acid and o-phenylenediamine is 2:3;

[0027] (2) ferric nitrate is dissolved in ethanol, the mass ratio of terephthalic acid and ferric nitrate is: 2: 3;

[0028] (3) Mix the two solutions obtained, and then sonicate to obtain a gel;

[0029] (4) drying the obtained gel and vacuumizing at 60°C;

[0030] (5) Fe-N-C composite material was prepared by high-temperature carbonization, the inert gas was high-purity argon, the carbonization temperature was 900°C, and the heating rate was 5°C / min. After reaching the target temperature, keep it warm for 2 hours;

[0031] (6) Pickling and drying the prepared Fe-N-C composite material, the acid used is hydrochloric acid with a concentration of 1 mol / L, and stirring for 8 hours for pickling.

Embodiment 2

[0033] The difference from Example 1 is that the mass ratio of terephthalic acid to o-phenylenediamine is 1:1, and the finally obtained composite material is denoted as Fe-N-C-1.

Embodiment 3

[0035] The difference from Example 1 is that the mass ratio of terephthalic acid to o-phenylenediamine is 1:2, and the finally obtained composite material is recorded as Fe-N-C-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com