Preparation method and application of LiNi<0.8>Co<0.2>O<2> material

A hydrothermal reaction and nickel salt technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of no electrochemical activity, difficult oxidation, etc., achieve good structural order, and improve electrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

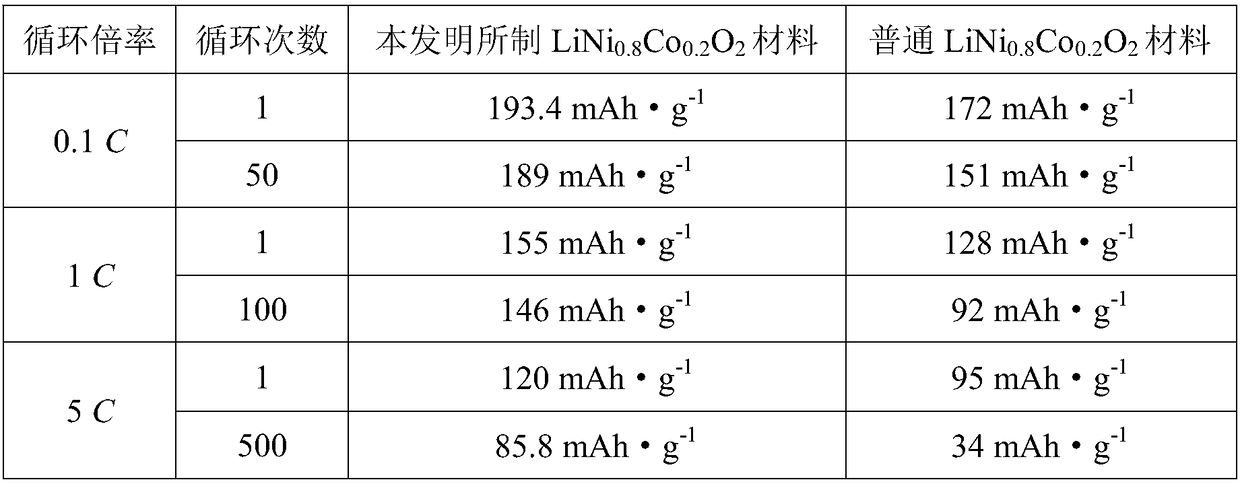

Examples

Embodiment 1

[0029] This embodiment provides a LiNi battery positive electrode 0.8 co 0.2 o 2 The preparation method of material, comprises the steps:

[0030] 1) Weigh 0.2551g of lithium acetate, 0.4977g of nickel acetate, 0.1246g of cobalt acetate and 0.3003g of urea into a 50mL beaker, add 40g of deionized water to obtain a mixed solution;

[0031] 2) ultrasonically stirring the mixed solution to completely dissolve all the materials to obtain a light yellow solution;

[0032] 3) Pour the solution into a 50mL hydrothermal reaction kettle, carry out solvothermal reaction in a forced air drying oven at 160°C, and naturally cool to room temperature after reacting for 10 hours;

[0033] 4) Transfer the precursor solution obtained by the hydrothermal reaction to a beaker, place the beaker in a water bath and heat and stir at a constant temperature of 80°C to remove the water in the solution;

[0034] 5) Put the beaker containing the dried product into a vacuum oven at 120°C for further d...

Embodiment 2

[0042] This embodiment provides a LiNi battery positive electrode 0.8 co 0.2 o 2 The preparation method of material, comprises the steps:

[0043] 1) Weigh 0.2551g of lithium acetate, 0.4977g of nickel acetate, 0.1246g of cobalt acetate and 0.3003g of urea into a 50mL beaker, add 40g of deionized water to obtain a mixed solution;

[0044] 2) ultrasonically stirring the mixed solution to completely dissolve all the materials to obtain a light yellow solution;

[0045] 3) Pour the solution into a 50mL hydrothermal reaction kettle, carry out solvothermal reaction in a forced air drying oven at 155°C, and naturally cool to room temperature after reacting for 12 hours;

[0046] 4) Transfer the precursor solution obtained by the hydrothermal reaction to a beaker, place the beaker in a water bath and heat and stir at a constant temperature of 80°C to remove the water in the solution;

[0047] 5) Put the beaker containing the dried product into a vacuum oven at 120°C for further d...

Embodiment 3

[0050] This embodiment provides a LiNi battery positive electrode 0.8 co 0.2 o 2 The preparation method of material, comprises the steps:

[0051] 1) Weigh 0.2551g of lithium acetate, 0.4977g of nickel acetate, 0.1246g of cobalt acetate and 0.3003g of urea into a 50mL beaker, add 40g of deionized water to obtain a mixed solution;

[0052] 2) ultrasonically stirring the mixed solution to completely dissolve all the materials to obtain a light yellow solution;

[0053] 3) Pour the solution into a 50mL hydrothermal reaction kettle, carry out solvothermal reaction in a forced air drying oven at 165°C, and naturally cool to room temperature after reacting for 8 hours;

[0054] 4) Transfer the precursor solution obtained by the hydrothermal reaction to a beaker, place the beaker in a water bath and heat and stir at a constant temperature of 80°C to remove the water in the solution;

[0055] 5) Put the beaker containing the dried product into a vacuum oven at 120°C for further dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com