Zinc oxide/titanium oxide double-layer nanorod array heterojunction structure and preparation method thereof

A nanorod array, titanium oxide technology, applied in nanotechnology, nanotechnology, semiconductor/solid-state device manufacturing, etc., to achieve the effects of good structural consistency, enhanced light scattering, and highly ordered orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A zinc oxide / titanium oxide double-layer nanorod array heterojunction structure, the preparation of which comprises the following steps:

[0040] 1) With the cleaned FTO conductive glass as the substrate, TiO is sputtered on the substrate by radio frequency magnetron sputtering 2 Nanocrystalline seed layer film;

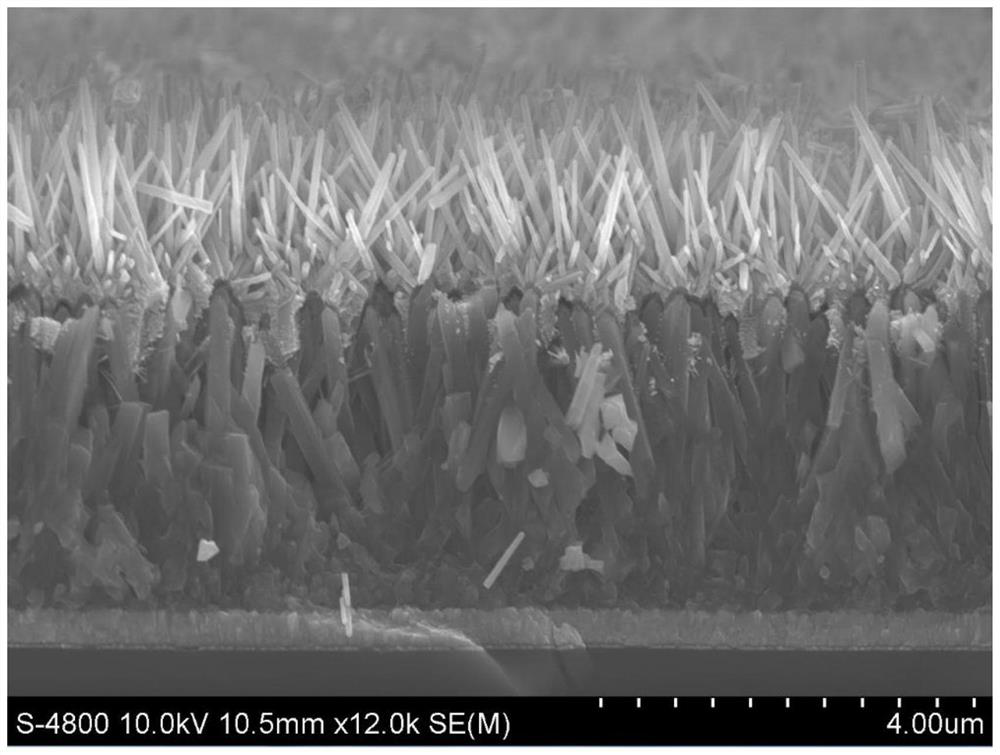

[0041]2), grow TiO in step 1) 2 Nanocrystalline seed layer film of FTO conductive glass into TiO 2 The hydrothermal reaction was carried out in the precursor solution (the hydrothermal reaction temperature was 160°C, and the hydrothermal reaction time was 4h), so that the TiO 2 Growth of TiO on Nanocrystalline Seed Layer Thin Films 2 nanorod arrays;

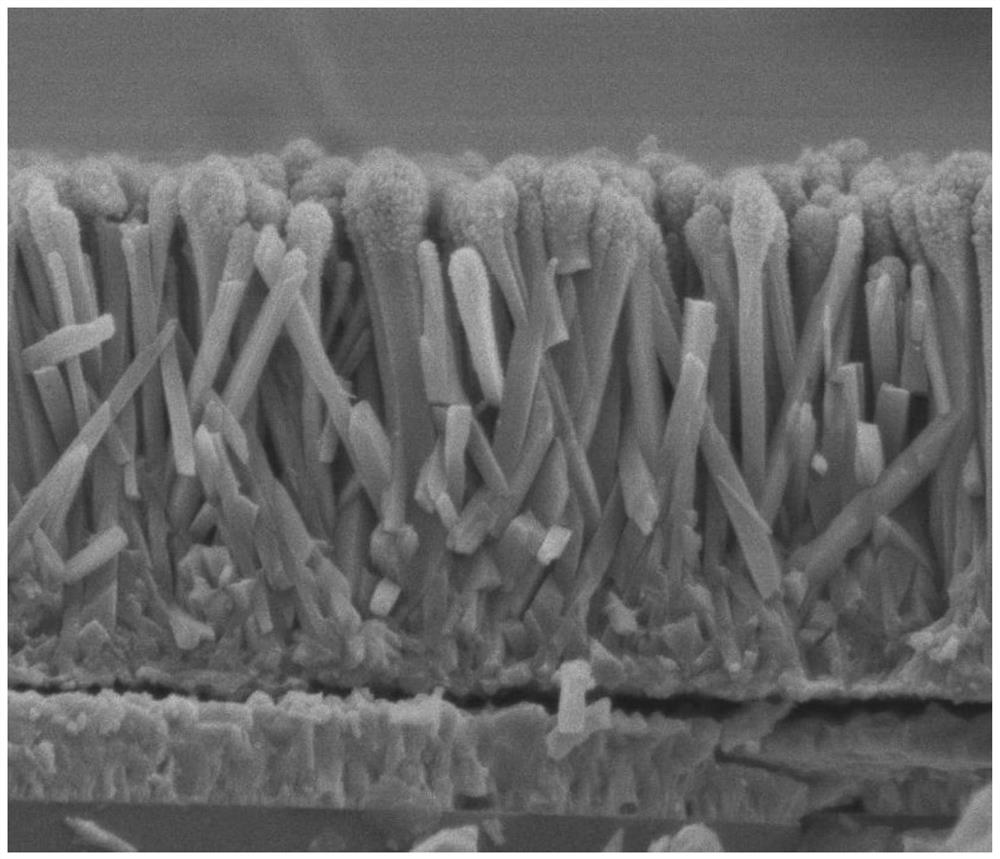

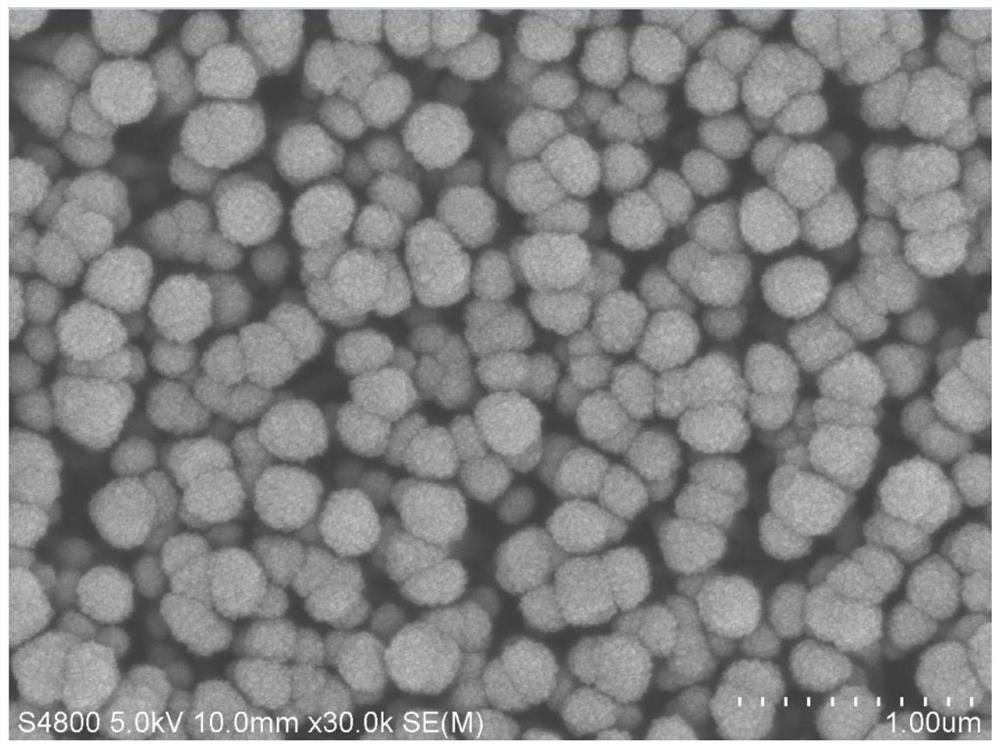

[0042] 3), with TiO grown in step 2) 2 The FTO conductive glass of the nanorod array was used as the substrate, and the TiO 2 The top of the nanorod array was deposited to obtain ZnO nanoparticles, and after the sputtering was completed, the FTO conductive glass was annealed in air at 450°C for 60min, there...

Embodiment 2

[0053] A zinc oxide / titanium oxide double-layer nanorod array heterojunction structure, the preparation of which comprises the following steps:

[0054] 1) With the cleaned FTO conductive glass as the substrate, TiO is sputtered on the substrate by radio frequency magnetron sputtering 2 Nanocrystalline seed layer film;

[0055] 2), grow TiO in step 1) 2 Nanocrystalline seed layer film of FTO conductive glass into TiO 2 The hydrothermal reaction was carried out in the precursor solution (the hydrothermal reaction temperature was 160°C, and the hydrothermal reaction time was 7h), so that the TiO 2 Growth of TiO on Nanocrystalline Seed Layer Thin Films 2 nanorod arrays;

[0056] 3), with TiO grown in step 2) 2 The FTO conductive glass of the nanorod array was used as the substrate, and the TiO 2 The top of the nanorod array was deposited to obtain ZnO nanoparticles, and after the sputtering was completed, the FTO conductive glass was annealed in air at 450°C for 60min, ther...

Embodiment 3

[0061] A zinc oxide / titanium oxide double-layer nanorod array heterojunction structure, the preparation of which comprises the following steps:

[0062] 1) With the cleaned FTO conductive glass as the substrate, TiO is sputtered on the substrate by radio frequency magnetron sputtering 2 Nanocrystalline seed layer film;

[0063] 2), grow TiO in step 1) 2 Nanocrystalline seed layer film of FTO conductive glass into TiO 2 The hydrothermal reaction was carried out in the precursor solution (the hydrothermal reaction temperature was 160°C, and the hydrothermal reaction time was 10h), so that the TiO 2 Growth of TiO on Nanocrystalline Seed Layer Thin Films 2 nanorod arrays;

[0064] 3), with TiO grown in step 2) 2 The FTO conductive glass of the nanorod array was used as the substrate, and the TiO 2 The top of the nanorod array was deposited to obtain ZnO nanoparticles, and after the sputtering was completed, the FTO conductive glass was annealed in air at 450°C for 60min, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com