A microwave device surface processing device and method for suppressing secondary electron emission

A technology of secondary electron emission and microwave devices, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of high cost, reduced microwave transmission performance of silver metal, and complicated process, so as to reduce size and position errors , high automatic processing capacity, and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

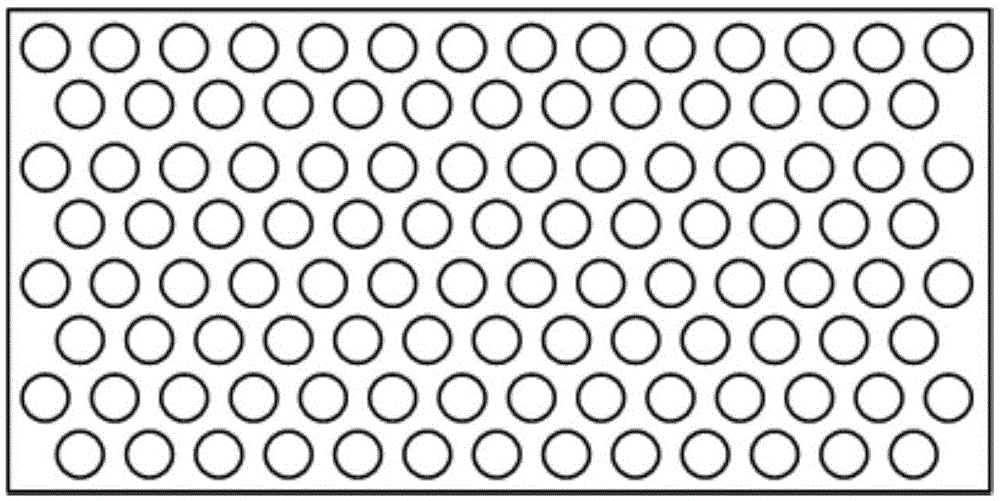

[0038] Such as figure 1 As shown, the microwave device surface texturing device of the present invention is composed of a laser output module 1 , a microlens 2 , a moving platform 4 and a control module 5 . The microwave device 3 to be processed is placed on the top surface of the mobile station 4, and the control module 5 outputs control signals to the laser output module 1 and the mobile station 4 to control the laser output power, the interval time, the moving distance and the moving time of the mobile station, and the microwave device is completed. 3 Surface deep hole array texture treatment. The laser beam can be a femtosecond laser or a nanolaser.

[0039] The working process of the microwave device surface texture device of the present invention is as follows: start the device, the control module 5 outputs a control signal to the laser output module 1, and the laser output module 1 is used to output a single beam of laser that can produce the effect of etching and remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com