Vacuum bonding method for full-color silicon-based oled microdisplay devices

A micro-display device, silicon-based technology, applied in semiconductor devices, electric solid-state devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of high color filter material requirements, OLED material damage, etc. Good water and oxygen barrier performance, avoid the effect of color mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment discloses a vacuum bonding method for a full-color silicon-based OLED microdisplay device, which includes the following steps:

[0051] Step 1, after cleaning the silicon substrate containing OLED and CMOS circuits and the color filter that have been encapsulated by thin film, drying;

[0052] Step 2, coating the frame sealant on the color filter, and coating the filling material on the silicon substrate containing OLED and CMOS circuits;

[0053] Step 3. Transfer the coated color filter and the silicon substrate to the vacuum chamber until the vacuum degree drops below 50Pa to carry out alignment bonding, and select several points on the bonded sample, and place the Spot UV pre-curing, UV illumination is 600mW / cm 2 above;

[0054] Step 4. Transfer the pre-cured sample to the UV irradiation device for UV curing, and set the UV illumination to 600mW / cm 2 ;

[0055] Step 5, cutting the cured sample into lobes to obtain the product.

[0056] Preferably...

Embodiment 2

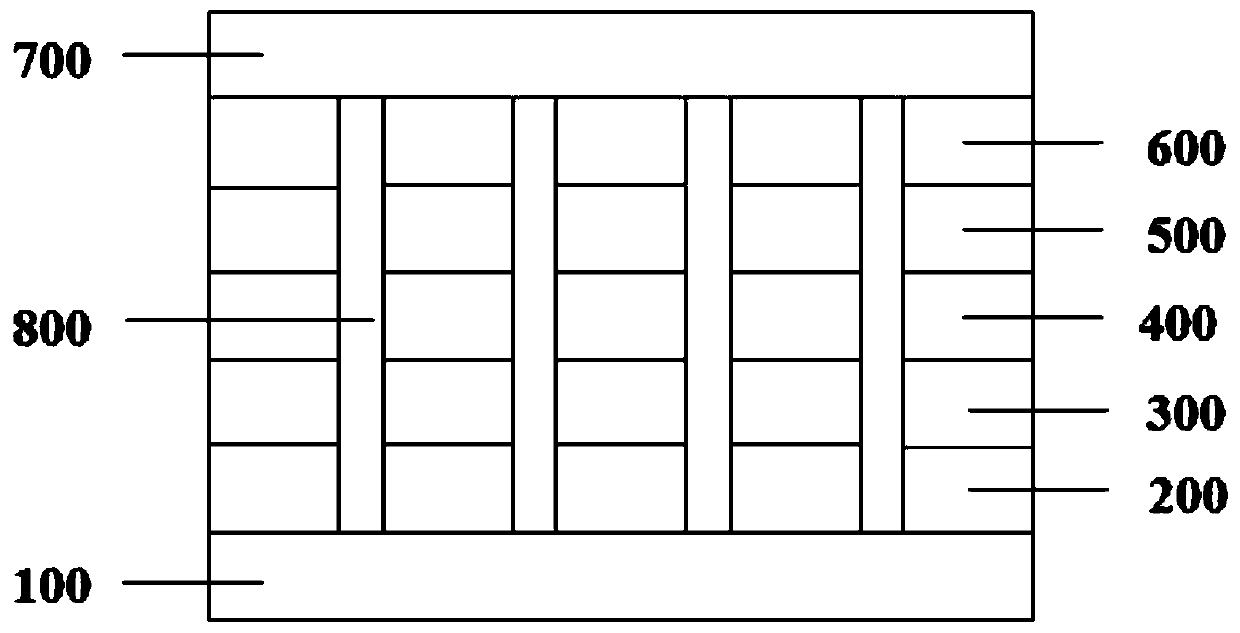

[0058] Such as Figure 1-3 As shown, the preparation method of the thin-film encapsulated silicon substrate containing OLED and CMOS circuits in Example 1 disclosed in this embodiment includes the following steps:

[0059] S1. Fabricate the pixel anode 200 on the CMOS circuit silicon substrate 100;

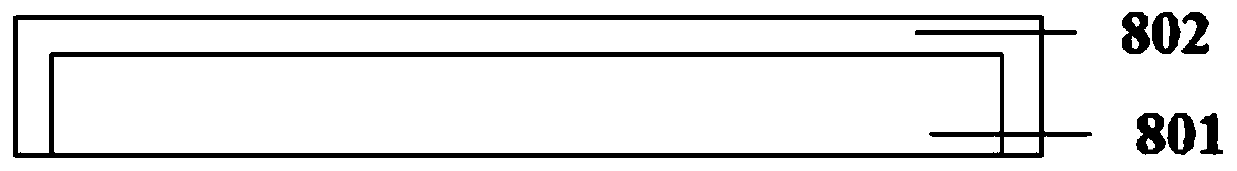

[0060] S2. Fabricate a reflective barrier layer 800 at the interval between adjacent pixel anodes 200;

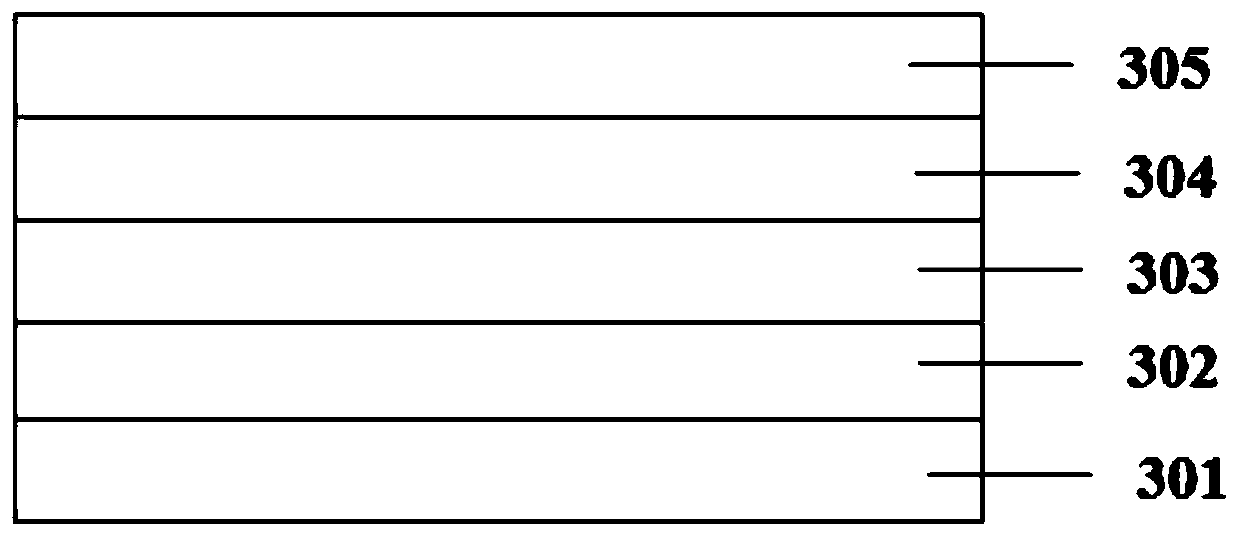

[0061] S3. Using an organic layer mask, sequentially vapor-deposit a hole injection layer HIL301, a hole transport layer HTL302, a light emitting layer EML303, an electron transport layer ETL304, an electron injection layer EIL305, and a transparent cathode 400 on the pixel anode 200;

[0062] S4, encapsulating the film layer 500 on the transparent cathode 400;

[0063] S5, making a color photoresist layer 600 on the packaging film layer 500;

[0064] S6. Paste the cover glass 700 on the color photoresist layer 600;

[0065] S7. After cutting, a product is obtained.

[006...

Embodiment 3

[0073] Such as Figure 4-5 As shown, the preparation method of the thin-film encapsulated silicon substrate containing OLED and CMOS circuits in Example 1 disclosed in this embodiment includes the following steps:

[0074] S1. Fabricate the pixel anode on the silicon substrate of the CMOS circuit by magnetron sputtering.

[0075] S2. Place the donor element of the red OLED thermal transfer layer on the anode of the pixel, and use the laser beam to pass through the mask plate and the objective lens to form a square beam, and the laser beam will prepare the red OLED thermal transfer layer on the donor element Correspondingly transferred to the anode of the pixel to form a red OLED heat transfer layer 201 .

[0076] S4. Place the donor element of the green OLED thermal transfer layer on the anode of the pixel, use the laser beam to pass through the mask plate and the objective lens to form a square beam, and the laser beam will prepare the green OLED thermal transfer layer on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com