Standby closing pipe for emergency maintaining of prestress steel cylinder concrete pipe line

A concrete pipe and prestressed steel technology, applied in the field of maintenance pipes, can solve the problems of easy leakage of flange joints, high installation requirements, complicated installation, etc., and achieve the effects of less joints, less leakage, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

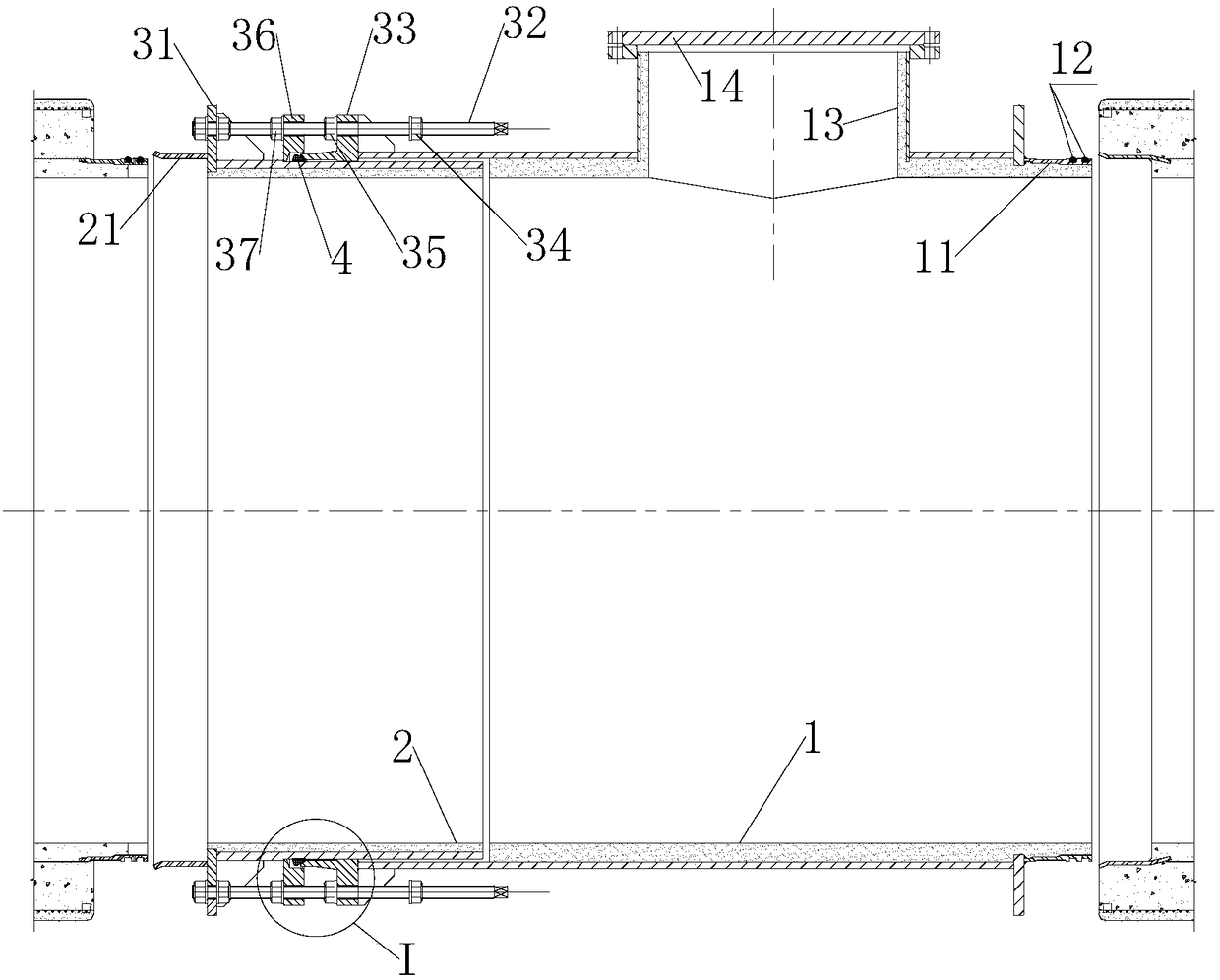

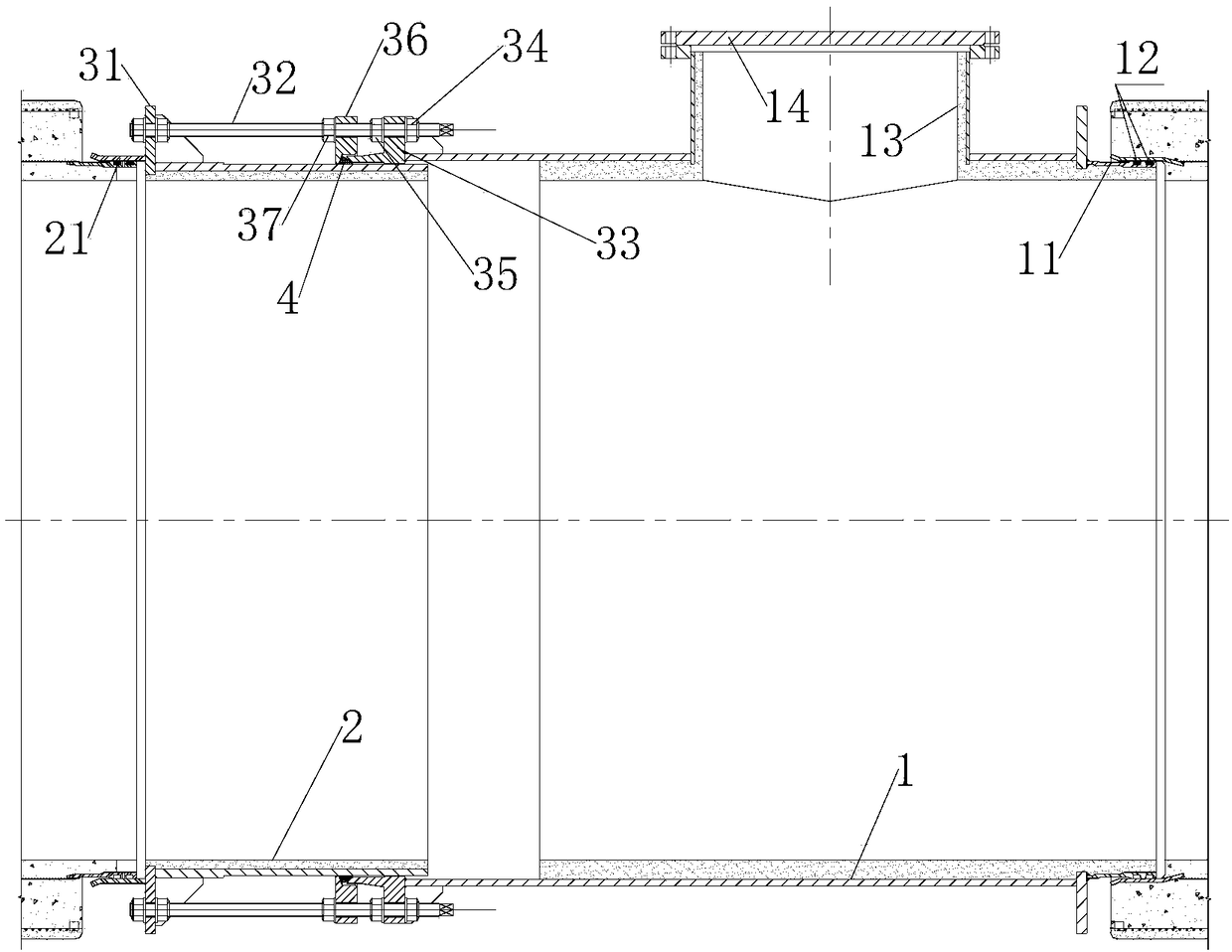

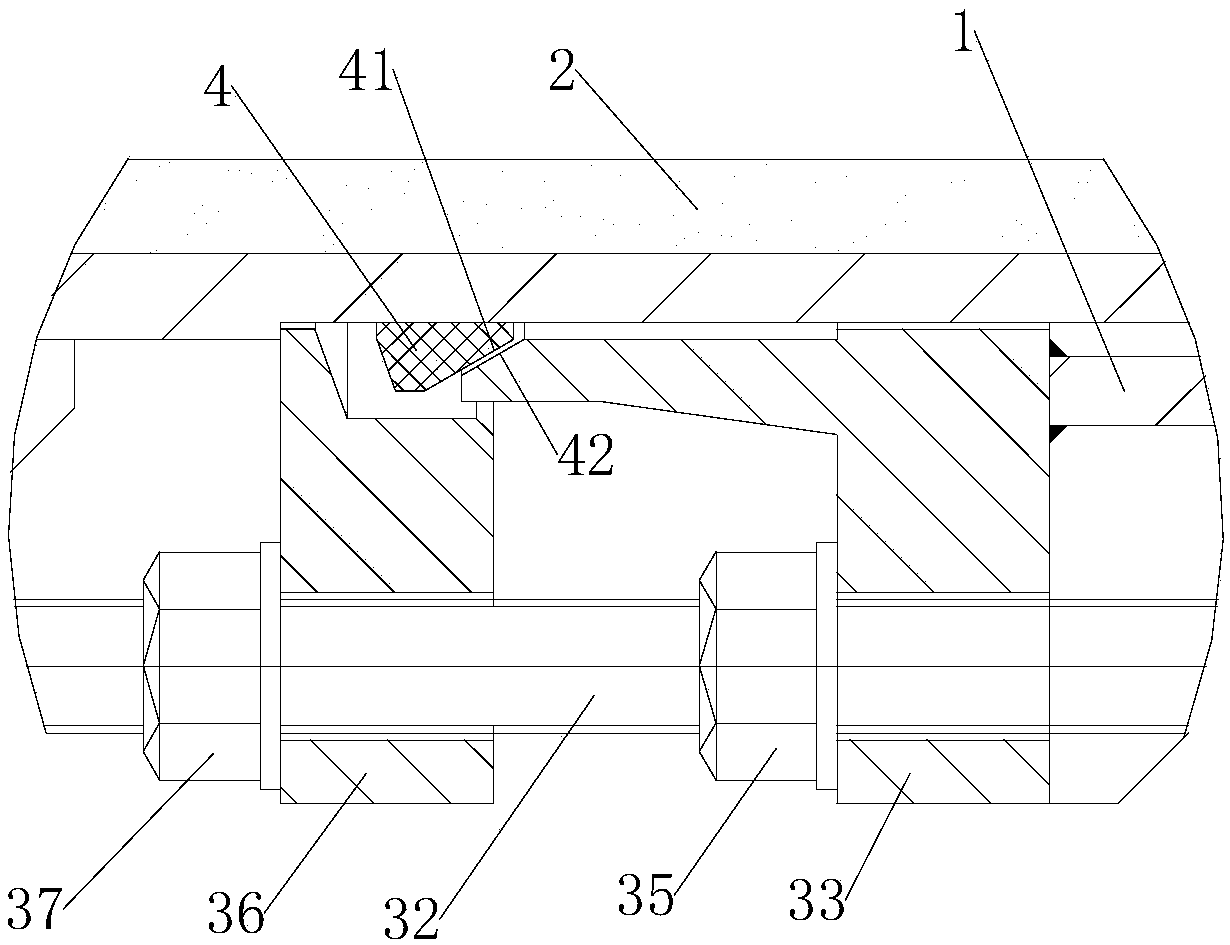

[0040] The present invention will be further described now in conjunction with accompanying drawing.

[0041] Such as figure 1 , figure 2 with image 3 As shown, the prestressed steel tube concrete pipe pipeline emergency repair standby closing pipe, including fixed pipe 1, telescopic pipe 2 and telescopic device; , A sealing ring 4 is installed between the telescopic tube 2 and the fixed tube 1. The total length of the extension tube 2 is exactly the length of the standard prestressed steel tube concrete tube. When the expansion tube 2 is retracted, it is convenient to place the spare closing tube for emergency repair of the prestressed steel tube concrete tube pipeline in the middle of the prestressed steel tube concrete pipeline. .

[0042] The end of the telescopic tube 2 away from the fixed tube 1 is provided with a socket steel ring 21 . The other end of the fixed pipe 1 is provided with a socket steel ring 11, and an O-shaped sealing ring 12 is housed on the socke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com