Surface polishing technology of magnesium alloy intravascular stent and assisting mechanism

A magnesium alloy blood vessel and surface polishing technology, which is applied to polishing compositions containing abrasives, electrolytic processes, electrolytic components, etc., can solve the problem of high surface structure requirements, complex processes and accessories, and difficult magnesium alloy polishing processes. Requirements for vascular stents and other issues to achieve the effect of improving surface quality and ensuring polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] S1, the magnesium alloy vascular stent is fixed, and then the surface of the magnesium alloy vascular stent is mechanically polished. The polishing agent is a mixture of 0.1 μm diamond and absolute ethanol, and the volume ratio is 1:20.

[0041] S2, add 300ml of acetone and 100ml of absolute ethanol into a 1000ml beaker, place the mechanically polished magnesium alloy stent in the beaker, and clean it with ultrasonic vibration at 20°C for 15 minutes.

[0042]S3, add 300ml of deionized water to a 1000ml beaker, then add 150ml of phosphoric acid, 10ml of nitric acid, 20ml of absolute ethanol, and 20g of ammonium hydrofluoride to make a pickling solution, and put the decontaminated magnesium alloy stent into the pickling solution solution, ultrasonic treatment at 25°C for 1.5 minutes; then, add 200ml of deionized water to a 1000ml beaker, add 2.0g of analytically pure potassium hydroxide and pure sodium carbonate, and configure it into an alkaline cleaning solution, and the...

Embodiment 2

[0047] Example 2 of the present invention is basically the same as Example 1, except that: in S1, the volume ratio of diamond in the polishing agent to absolute ethanol is 1:25; in S2, the ultrasonic decontamination process is processed at 30°C 10 minutes; in S3, the ultrasonic treatment time was 2 minutes; in S4, the polishing temperature was 40°C, the voltage was 9V, and the polishing time was 2 minutes; in S5, the ultrasonic cleaning was 12 minutes, and the cleaning temperature was 30°C.

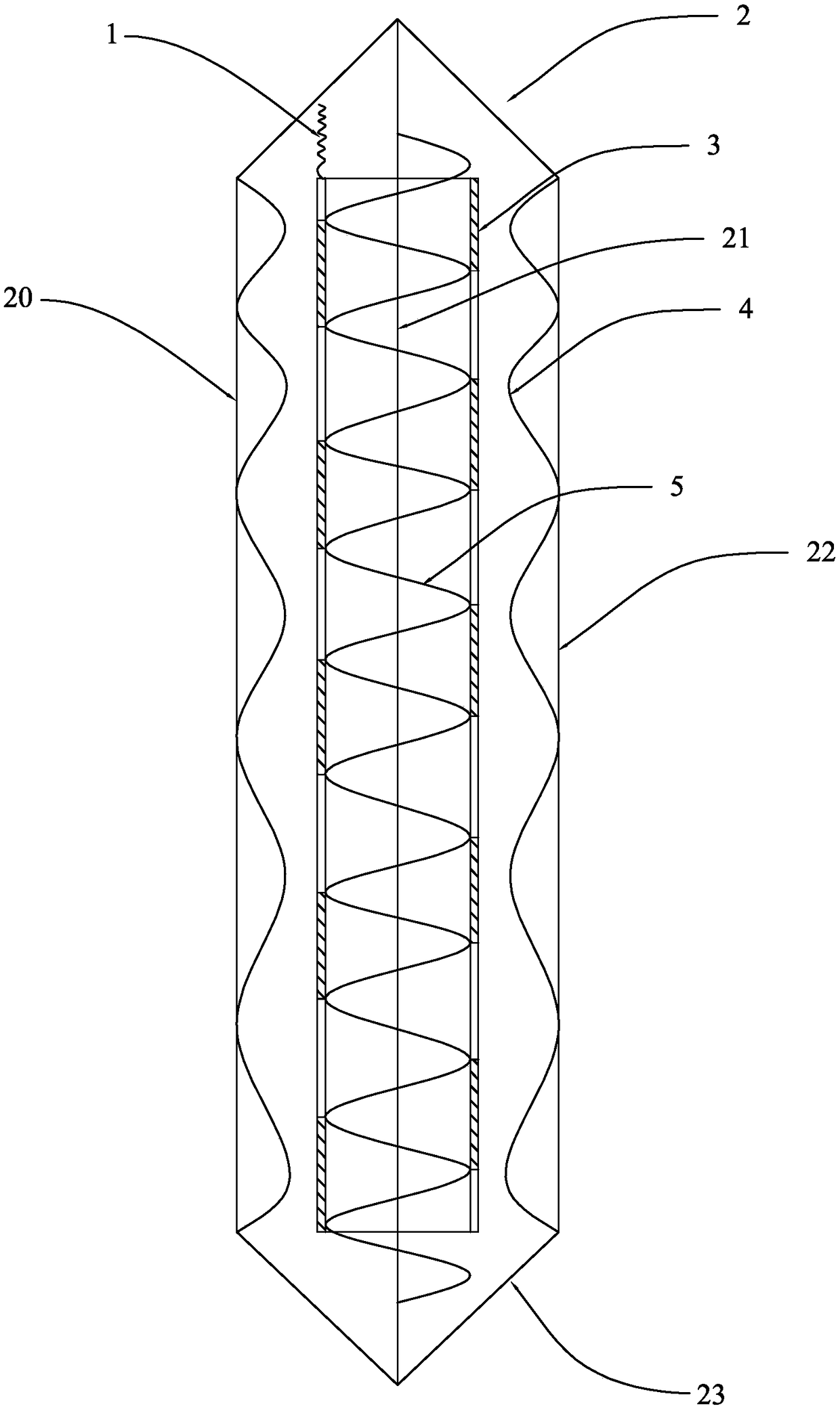

[0048] In order to ensure that the magnesium alloy stent is fully electrochemically polished, the present invention also provides an auxiliary mechanism, such as figure 2 , which includes an anode wire 1 and a cathode mesh cage 2. The anode wire 1 is used for fixed connection with the magnesium alloy vascular stent 3. In this embodiment, the anode wire 1 is selected as a U-shaped stainless steel wire. When installing, the U-shaped stainless steel wire crosses through the Through the holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com