Copper-plated steel wire and production method thereof

A production method and technology for copper-plated steel, applied in the field of electroplating, can solve problems such as poor corrosion resistance of steel, and achieve the effects of improving bonding force, eliminating concentration polarization, and continuously and rapidly depositing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

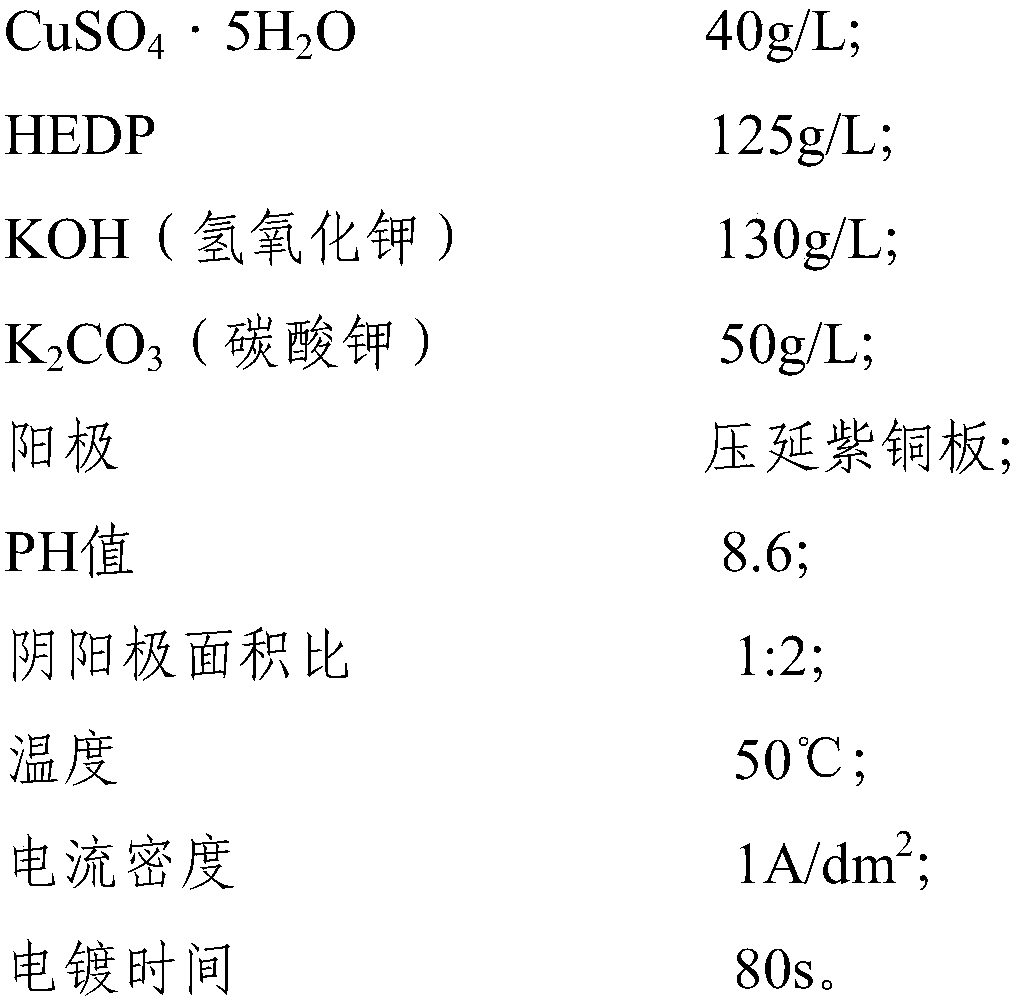

Embodiment 1

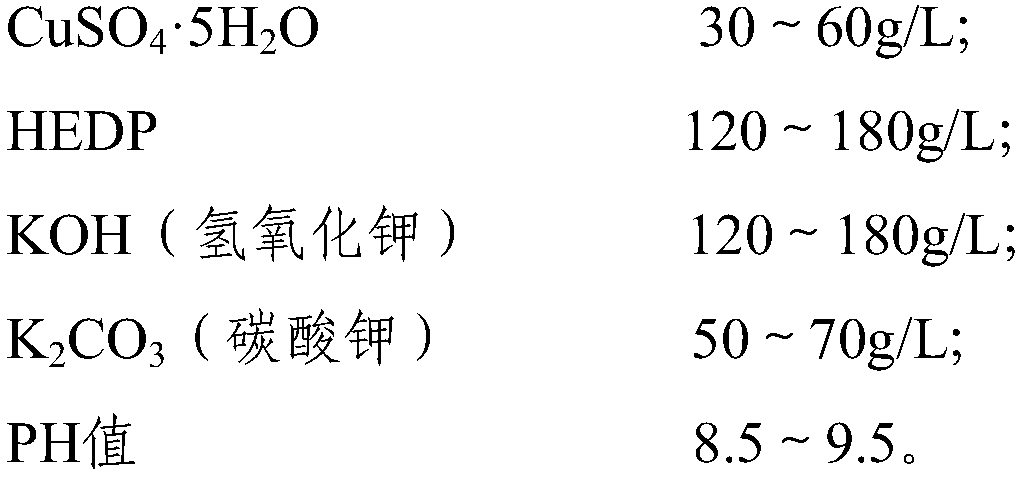

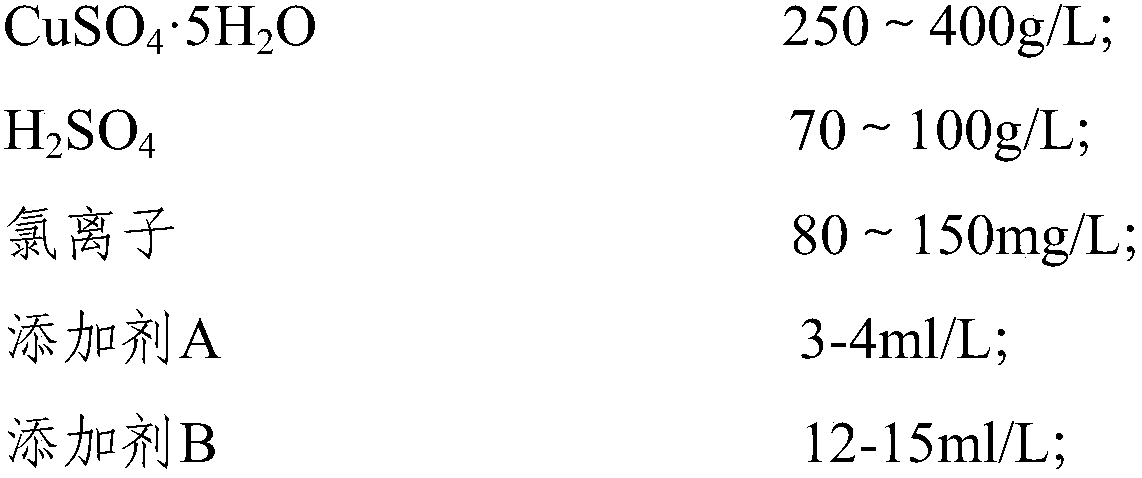

[0028] The present embodiment provides a kind of production method of copper-plated steel wire, comprising:

[0029] Process: feeding→chemical degreasing→ultrasonic degreasing→electrodegreasing→hot water washing→pickling→ultrasonic water washing→activation before pre-plating→copper pre-plating→water washing→activation before copper→acid thick copper plating→water washing→sealing→ Washing→drying→receiving. in:

[0030] Feeding: The low carbon steel wire rod is uncoiled, straightened and transported to the coating tank through the rotating feeding mechanism.

[0031] The specific operation steps of chemical degreasing are as follows: at a temperature of 65°C, let the low carbon steel wire rod pass through the chemical degreasing tank, and the temperature of the bath liquid is kept at 65°C through the heater.

[0032] The specific operation steps of ultrasonic degreasing are as follows: at a temperature of 65°C, let the low-carbon steel wire rod pass through the ultrasonic degr...

Embodiment 2

[0045] The present embodiment provides a kind of production method of copper-plated steel wire, comprising:

[0046] Process: feeding→chemical degreasing→ultrasonic degreasing→electrodegreasing→hot water washing→pickling→ultrasonic water washing→activation before pre-plating→copper pre-plating→water washing→activation before copper→acid thick copper plating→water washing→sealing→ Washing→drying→receiving. in:

[0047] Feeding: The low carbon steel wire rod is uncoiled, straightened and transported to the coating tank through the rotating feeding mechanism.

[0048] The specific operation steps of chemical degreasing are as follows: at a temperature of 72°C, let the low carbon steel wire rod pass through the chemical degreasing tank, and the temperature of the bath liquid is kept at 72°C through the heater.

[0049] The specific operation steps of ultrasonic degreasing are as follows: at a temperature of 70°C, let the low-carbon steel wire rod pass through the ultrasonic degr...

Embodiment 3

[0063] The present embodiment provides a kind of production method of copper-plated steel wire, comprising:

[0064] Process: feeding→chemical degreasing→ultrasonic degreasing→electrodegreasing→hot water washing→pickling→ultrasonic water washing→activation before pre-plating→copper pre-plating→water washing→activation before copper→acid thick copper plating→water washing→sealing→ Washing→drying→receiving. in:

[0065] Feeding: The low carbon steel wire rod is uncoiled, straightened and transported to the coating tank through the rotating feeding mechanism.

[0066] The specific operation steps of chemical degreasing are as follows: at a temperature of 80°C, let the low carbon steel wire rod pass through the chemical degreasing tank, and the temperature of the bath liquid is kept at 80°C through the heater.

[0067] The specific operation steps of ultrasonic degreasing are as follows: at a temperature of 78°C, let the low-carbon steel wire rod pass through the ultrasonic degr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com