C3N4-Mt-SO3H composite material as well as preparation and application thereof

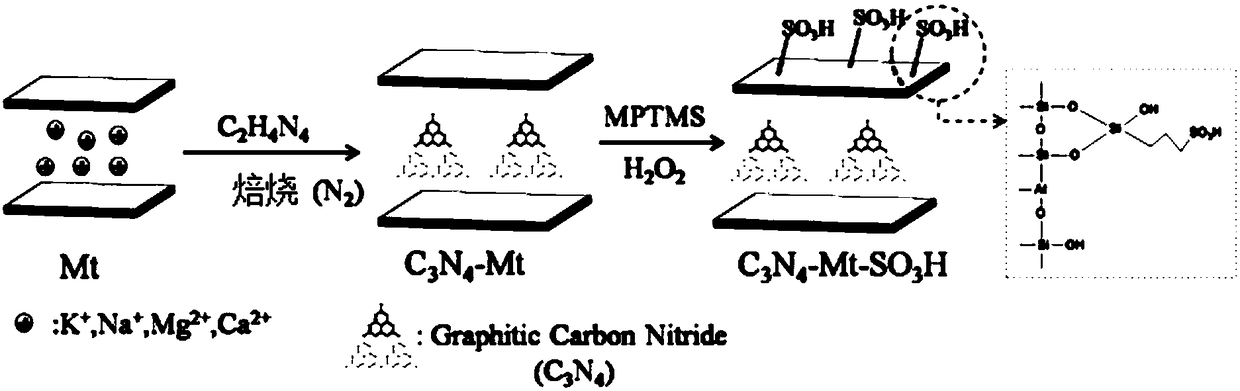

A technology of c3n4-mt-so3h and c3n4-mt-sh is applied in the field of C3N4-Mt-SO3H composite material and its preparation and application, which can solve the problems of expensive Pt, easy deactivation, and limited commercial application, and achieve The effects of large sample volume, effective transformation, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

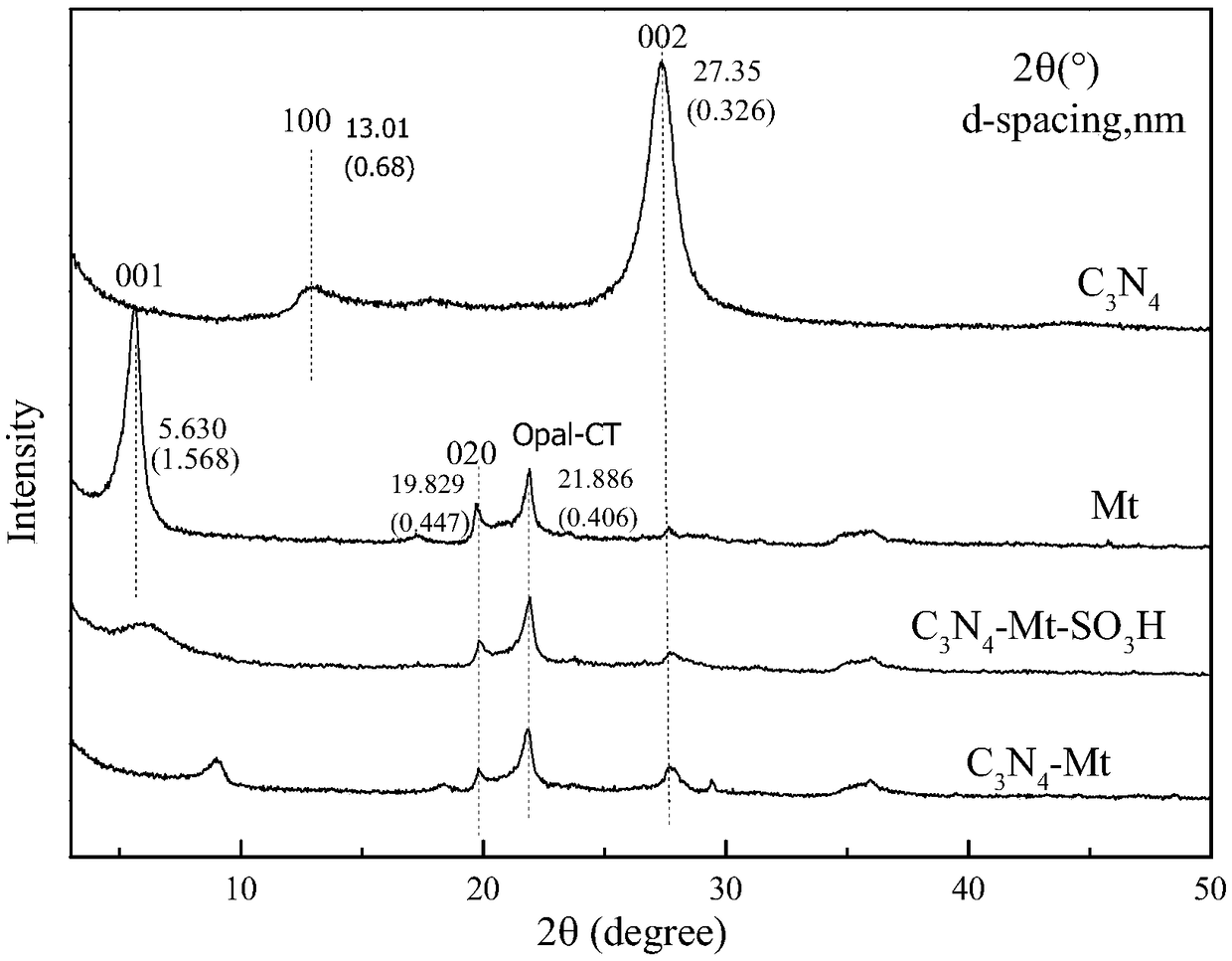

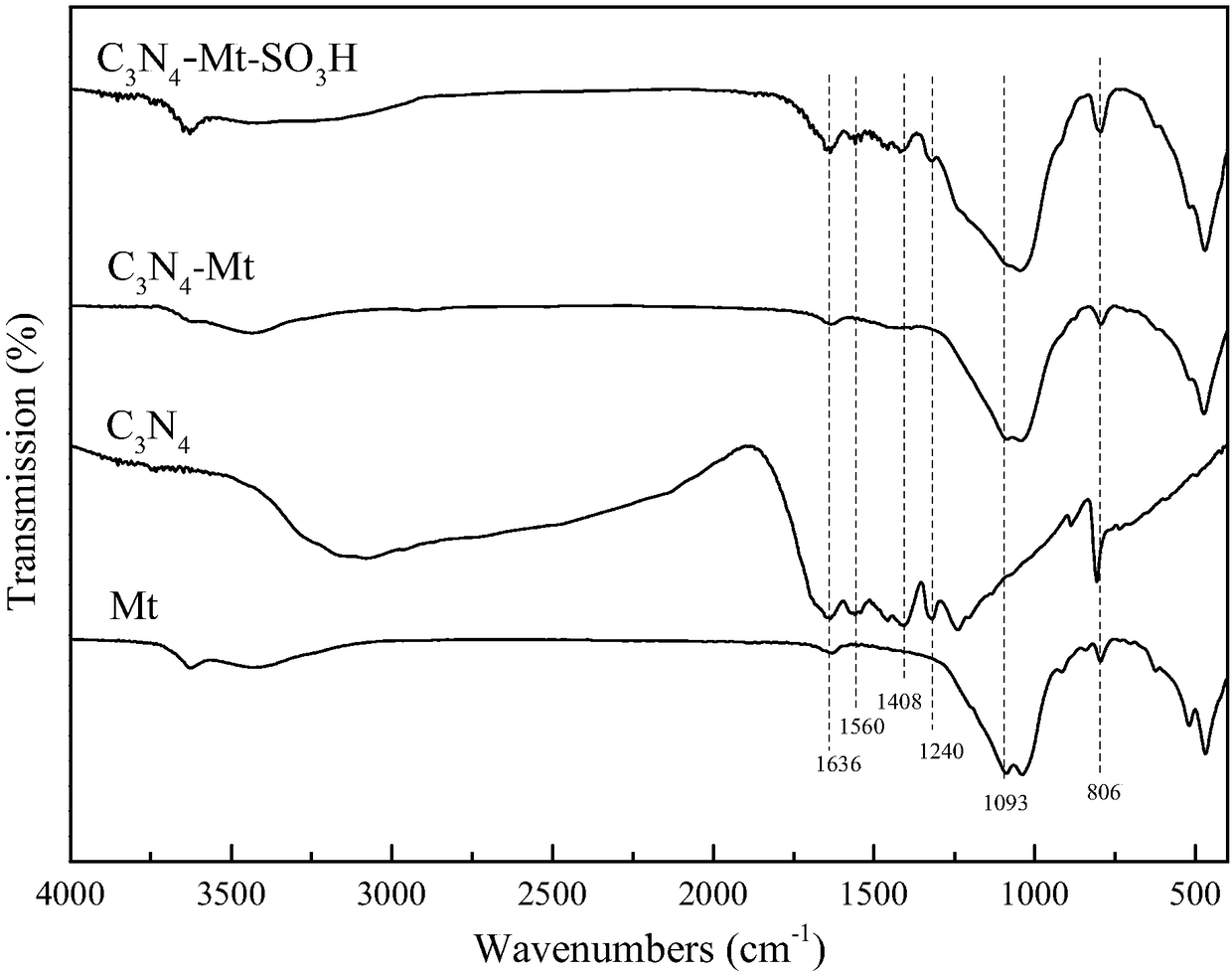

[0056] Weigh 5g of montmorillonite (the cation exchange capacity of the used montmorillonite, that is, CEC is 50mmol / 100g), put it in a round-bottomed flask, pour 50mL of deionized water, stir for 20min, and then add 0.42g of dicyandiamide (2CEC), Stir at 100 °C for 4 hours for exchange adsorption, then rotate the product to evaporate the water until no water, then put the solid into an evaporating dish, and dry it at 100 °C in a constant temperature drying oven. The dried solid is ground into powder and poured into Then put the quartz tank into the quartz sleeve of the single-tube tube furnace, and keep the sample in the constant temperature zone. After sealing, nitrogen was passed through for 1 h to remove the air in the quartz sleeve. The temperature of the tube furnace was raised from room temperature to 550°C at a rate of 2.5°C / min, kept at a constant temperature for 4 hours, and cooled naturally after the calcination to obtain product C. 3 N 4 -Mt composite. Weigh 2gC...

Embodiment 2

[0059] The mass of dicyandiamide in Example 1 was changed to 0.84g (4CEC), other steps were as in Example 1, and the catalyst prepared under this synthesis condition was recorded as Sample 2.

Embodiment 3

[0061] The mass of dicyandiamide in Example 1 was changed to 1.26g (6CEC), other steps were as in Example 1, and the catalyst prepared under this synthesis condition was recorded as Sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com