Shrimp meat separation device using vibration and separation method

A technology of separation method and separation device, which is applied in application, shrimp/lobster processing, and crustacean processing, etc. It can solve the problems of not being able to adapt to batch processing and long time, so as to improve the firmness of shrimp meat and facilitate operation , the effect of high work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

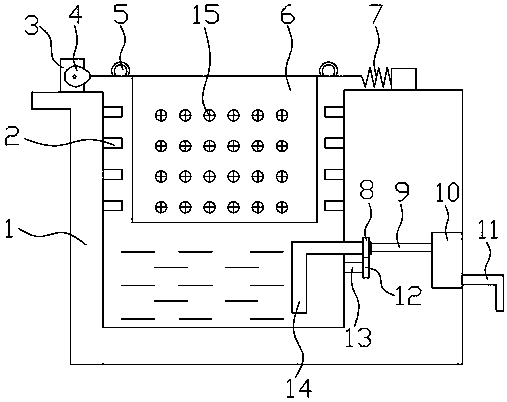

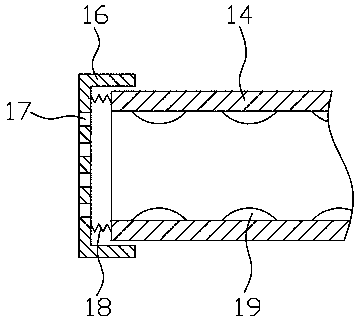

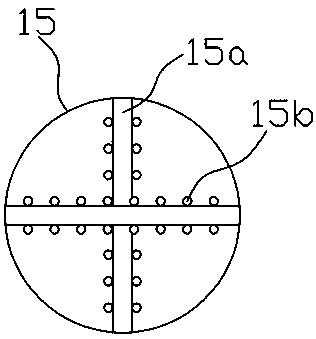

[0022] like Figure 1~4 As shown, the shrimp meat separation device adopting the vibration separation method includes a box body 1 and a vibrating screen 6 arranged inside the box body 1, one side of the vibrating screen 6 is connected with a block 4, and the other side of the vibrating screen 6 is connected with a sub-sieve The spring 7, the inner wall of the box body 1 at the lower end of the vibrating screen 6 is connected with a suction pipe 14, the suction pipe 14 is connected to the water pump 10 through the support pipe 9, the water pump 10 is connected with the discharge pipe 11, and the outer wall of the head end of the suction pipe 14 is connected with Connecting spring 18, connecting surface of connecting spring 18 is equipped with the movable cover 16 of lid hole 17, and vibrating screen 6 is the main component that shrimp meat separates, and vibrating screen 6 is connected with sub-sieve spring 7, makes vibrating screen 6 have enough vibration space, The vibrating...

Embodiment 2

[0032] like Figure 1~4 As shown, the working principle of the present invention is: put the crushed shrimp meat into the vibrating screen 6, turn on the high-speed motor 3 to make the block 4 rotate, and the vibrating screen 6 connected to the block 4 will continue to vibrate under the effect of the block. Vibration is generated, so that the shrimp meat continuously falls from the sieve hole 15 into the water body inside the box body 1. During the vibration process of the vibrating screen 6, the water spray pipe 2 sprays water to the vibrating screen 6 to promote the falling of the shrimp meat and enter the box body. 1. Shrimp meat and smaller shrimp shells in the internal water body are stratified, and the gear motor 13 starts to work, and the suction pipe 14 is adjusted to the height of the shrimp meat layer, and the water pump 10 starts to work, so that the suction pipe 14 will suck the shrimp. The meat is sucked, and the device is discharged from the discharge pipe 11 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com