Torsional vibration combined cold extrusion die

A technology of torsional vibration and cold extrusion, applied in the direction of metal extrusion dies, etc., can solve the problems of single form of flutter, the amplitude and frequency cannot be precisely controlled, etc., to achieve controllable vibration frequency and amplitude, large vibration output force, The effect of promoting metal flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

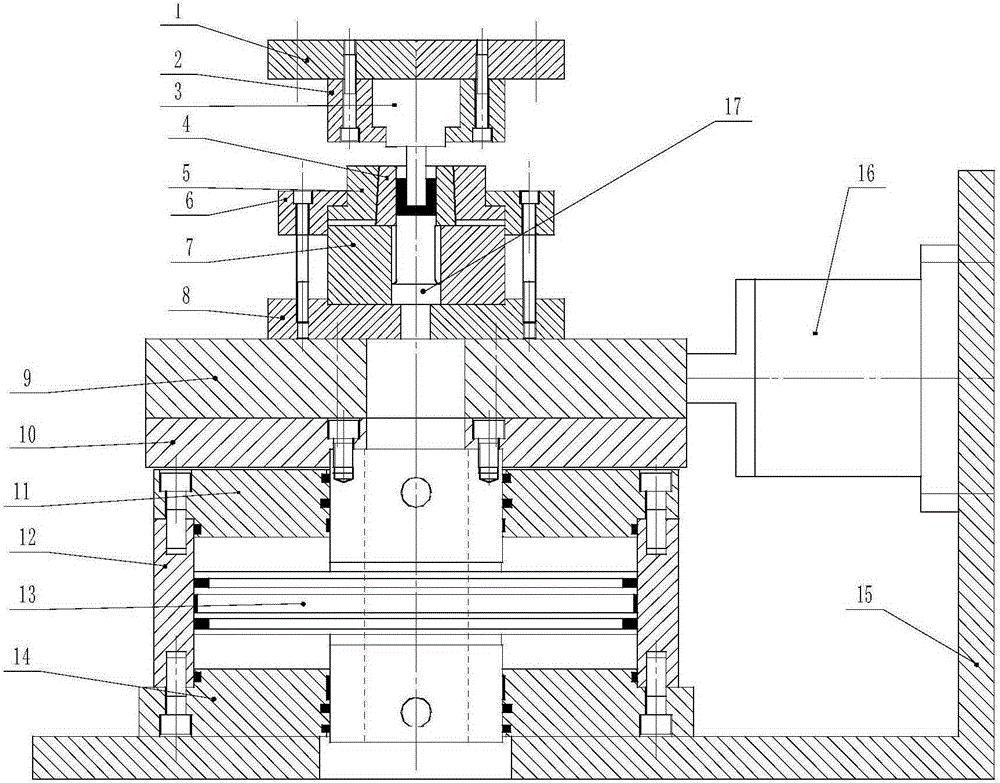

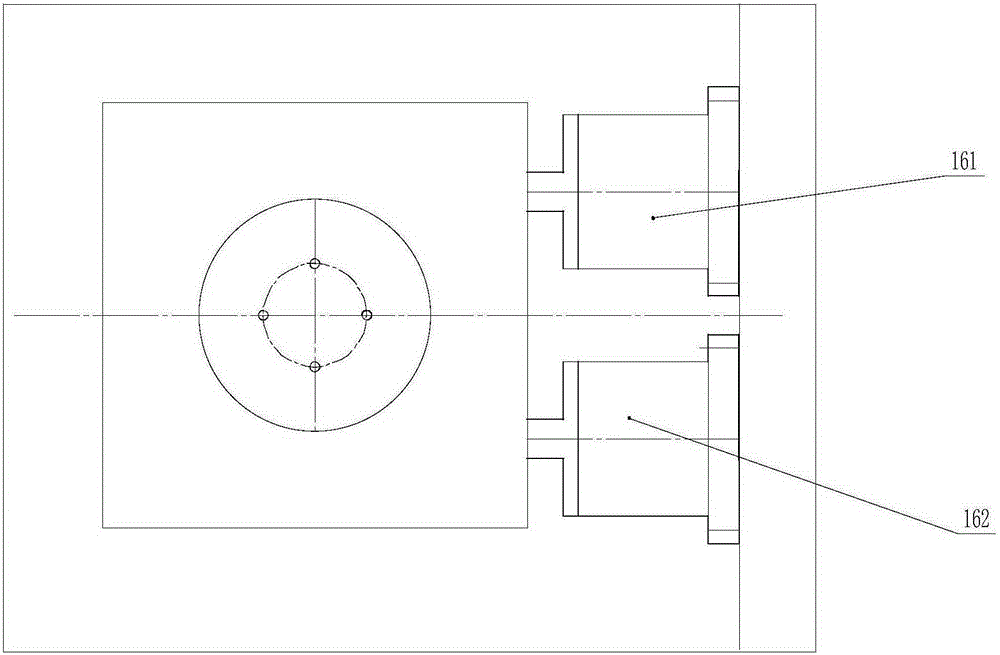

[0021] The torsional vibration compound cold extrusion die of the present invention includes a forming mechanism. The forming mechanism includes an upper punch 3, a die 4, an upper template 1, a punch fixing ring 2, a prestressing ring 5, a compression ring 6, a lower punch 17, a die gasket 7, a die fixing plate 8, The lower template 9, the upper punch 3 is installed in the punch fixing ring 2 of the upper template 1, the concave mold 4 positioned directly below the upper punch 3 is installed in the prestressing ring 5, the concave The mold 4 is in contact with the upper end surface of the die gasket 7 directly below; the lower punch 17 is installed in the die gasket 7; the compression ring 6 is set on the upper part of the prestressing ring 5, and the pressure The tight ring 6 is fixed on the die fixing plate 8 by bolts; the die fixing plate 8 is connected with the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com