Explosion-proof frequency converter cooling system and method

An explosion-proof frequency converter and cooling system technology, which is applied in the direction of cooling/ventilation/heating transformation, output power conversion device, electrical components, etc. Limited problems, to achieve the effect of improving explosion-proof performance, best cooling effect, and good electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

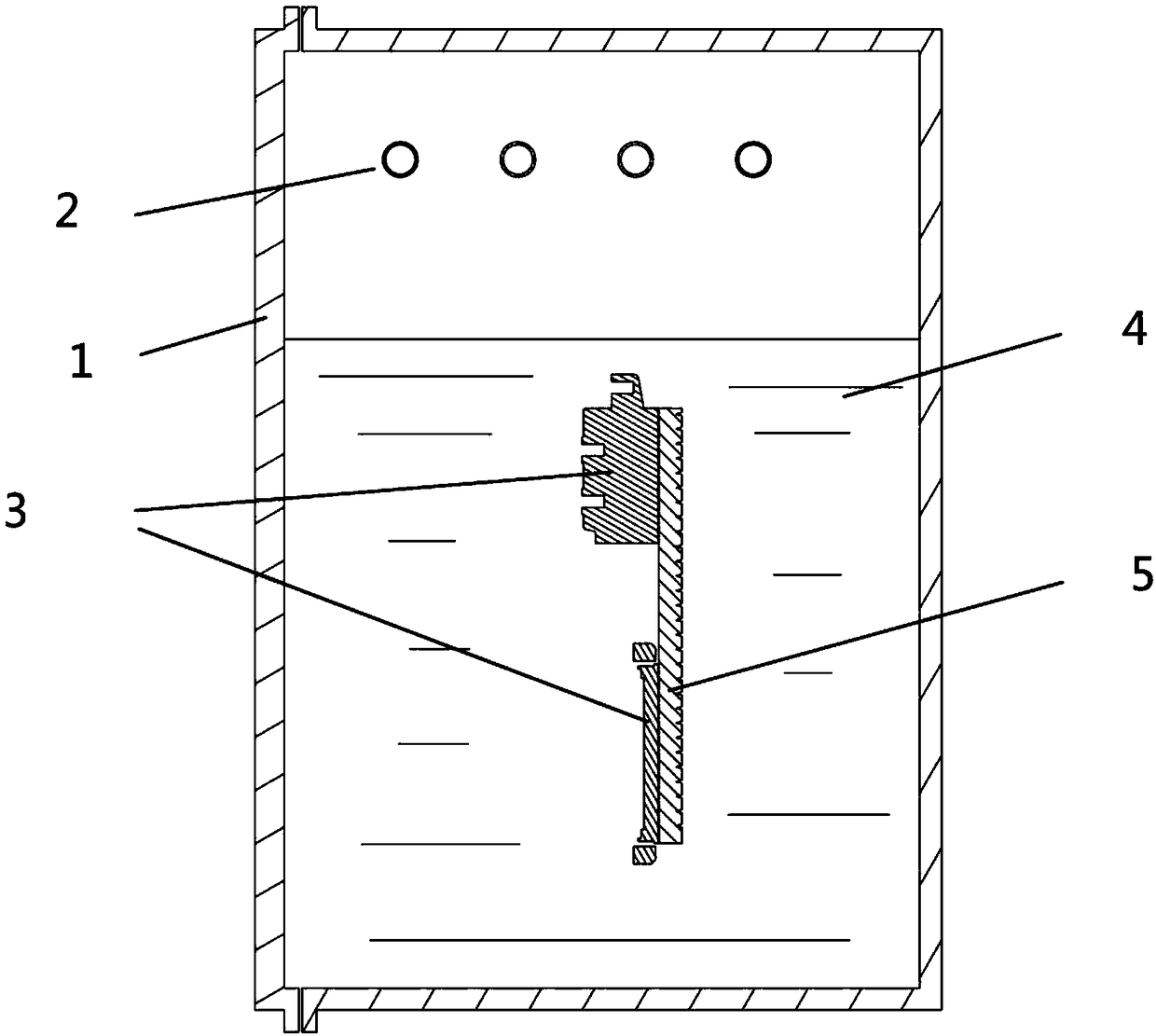

[0035] Such as figure 1 As shown, an explosion-proof inverter cooling system includes a housing 1, a condensation pipe 2 and a heat dissipation pipe.

[0036] A high-power device 3 of an explosion-proof frequency converter is arranged inside the housing 1 to protect and support the high-power device 3 . The casing 1 is equipped with a cooling liquid 4 , and the high-power device 3 is immersed in the cooling liquid 4 . The cooling liquid 4 can electrically insulate the high-power device 3 .

[0037] The heat dissipation plate 5 is arranged in the housing 1 and immersed in the cooling liquid 4 ; the high-power device 3 is arranged on the heat dissipation plate 5 . A large amount of heat generated by the high-power device 3 during operation is transferred to the cooling plate 5, and the temperature of the cooling plate 5 rises;

[0038] Condenser pipe 2 comprises body, inlet end and outlet end, and body is arranged in housing 1, and is positioned at the top of cooling liquid 4...

Embodiment 2

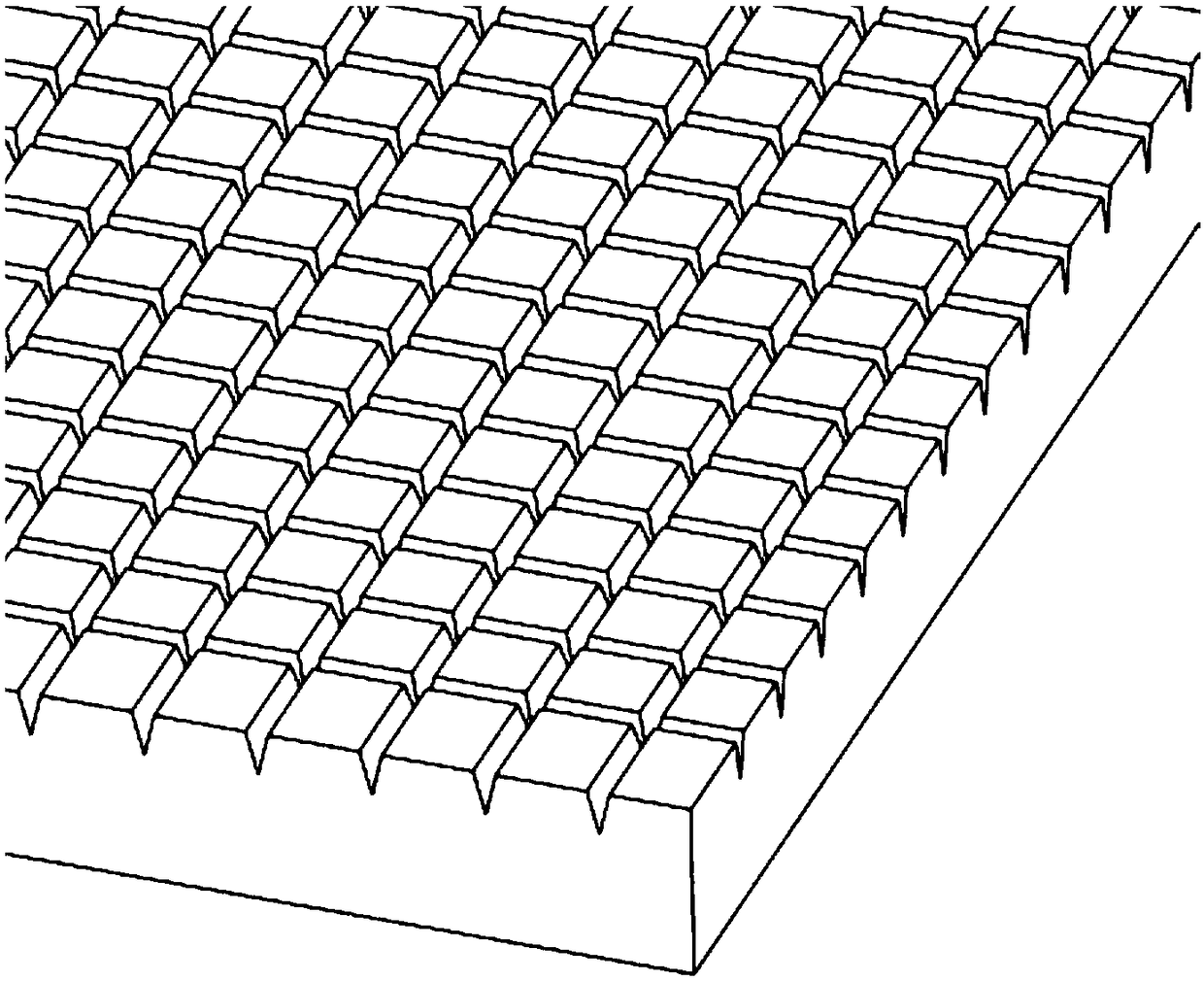

[0045] As shown in Embodiment 1, the only difference is that the surface of the radiator is provided with an enhanced boiling structure.

[0046] Such as figure 2 As shown, there are several protrusions on the enhanced boiling structure, and the protrusions increase the contact area between the cooling liquid 4 and the enhanced boiling structure, which can accelerate the heat transfer speed.

Embodiment 3

[0048] As shown in Embodiment 2, the only difference is that the condensation pipe 2 is a smooth-walled copper pipe.

[0049] The smooth-walled copper tube has a high thermal conductivity, which can quickly absorb the heat released when the steam condenses, and quickly transfer the heat to the cooling medium in the condensation pipe 2, and the cooling medium transports the heat to the explosion-proof frequency converter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com