A preparation method of wear-resistant steel with low cost and short production cycle

A production cycle, wear-resistant steel technology, applied in the field of steel, can solve the problems of many processes, high cost, long production cycle, etc., to achieve the effect of reducing processes, shortening the production cycle, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

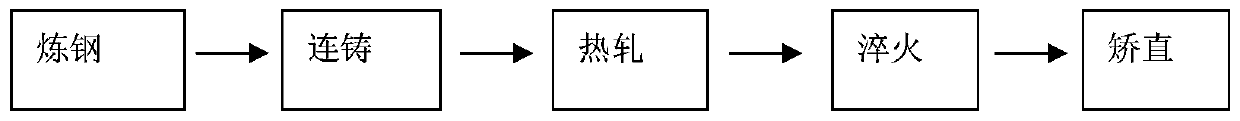

[0022] This embodiment is a preparation method of wear-resistant steel with low cost and short production cycle. The process line is as follows: figure 1 As shown, the design composition of the wear-resistant steel in this embodiment is: C: 0.15%, Si: 0.25%, Mn: 1.37%, Cr: 0.19%, Mo: 0.20%, Nb: 0.015%, Ti : 0.02%, B: 0.0013%, S: 0.0011%, P: 0.012%, O: 0.008%, N: 0.005%, and the balance is Fe.

[0023] Converter steelmaking is adopted according to the above composition, and the billet is continuously cast. The temperature of the heating furnace is 1200°C, and the heating is divided into three stages. The preheating section is 500±20°C, the heating section is 1220±20°C, and the soaking section is 1200± 20°C, the holding time is 5 hours, and after the furnace, rough rolling and finishing rolling are carried out on a plate rolling mill in two stages and multi-pass rolling to obtain a finished product with a thickness of 6mm. After rolling, it is sent to a quenching machine for qu...

Embodiment 2

[0028] This embodiment is a preparation method of wear-resistant steel with low cost and short production cycle. The process line is as follows: figure 1 As shown, the design composition of the wear-resistant steel in this embodiment is: C: 0.14%, Si: 0.26%, Mn: 1.24%, Cr: 0.22%, Mo: 0.14%, Nb: 0.012%, Ti : 0.018%, B: 0.0017%, S: 0.0007%, P: 0.010%, O: 0.007%, N: 0.005%, and the balance is Fe.

[0029] Converter steelmaking is adopted according to the above composition, and continuous casting is made into slabs. The temperature of the heating furnace is 1180°C, and the heating is divided into three stages. The preheating section is 500±20°C, the heating section is 1220±20°C, and the soaking section is 1200± 20°C, the holding time is 5 hours, and after the furnace, rough rolling and finishing rolling are carried out on a plate rolling mill in two stages and multi-pass rolling to obtain a finished product with a thickness of 16 mm. After rolling, it is sent to a quenching machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com