An Ultrasonic Vibration Assisted Rolling Method for Production of Low Residual Stress Aluminum Alloy Strip

A technology of aluminum alloy strip and ultrasonic vibration, which is applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of high production cost, increased production cost, and increased difficulty in mold design and repair, so as to improve the quality of aluminum alloy stamping. performance, effect of low residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

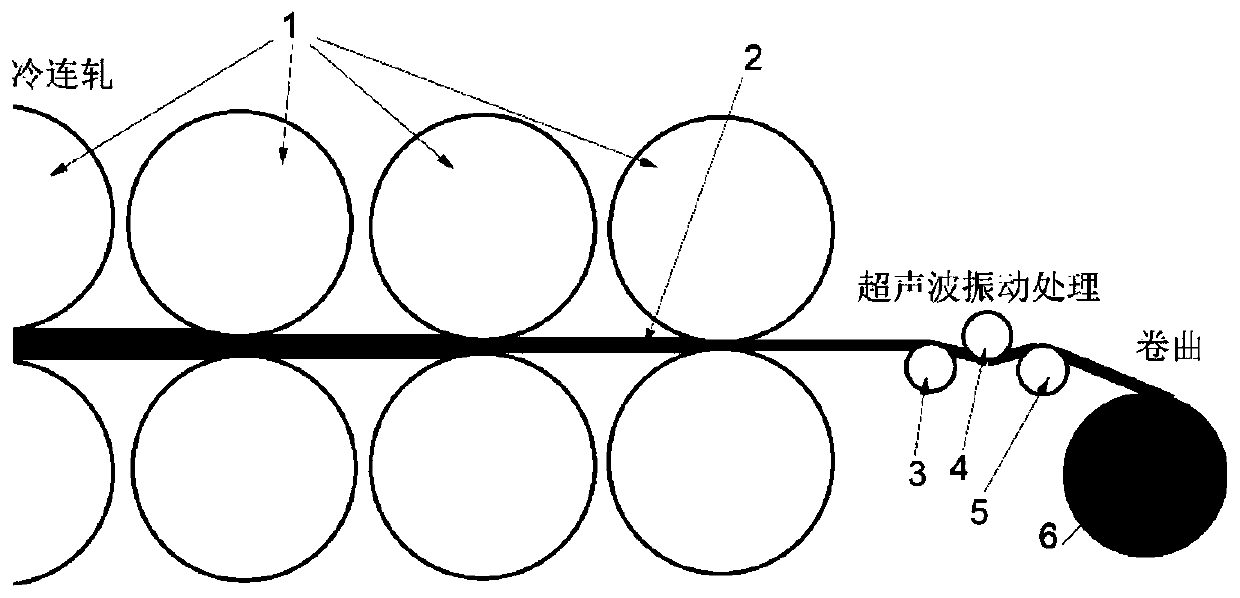

[0026] To produce 0.5mm low residual stress AA6061 aluminum alloy strip, the steps are as follows:

[0027] The first step: using the aluminum alloy AA6061 medium and heavy plate as the raw material, the initial thickness of the rolled piece is 3mm, and the aluminum alloy is continuously cold-rolled. The thickness of the cold-rolled product is 0.5mm, and the residual stress inside the rolled piece is 120MPa.

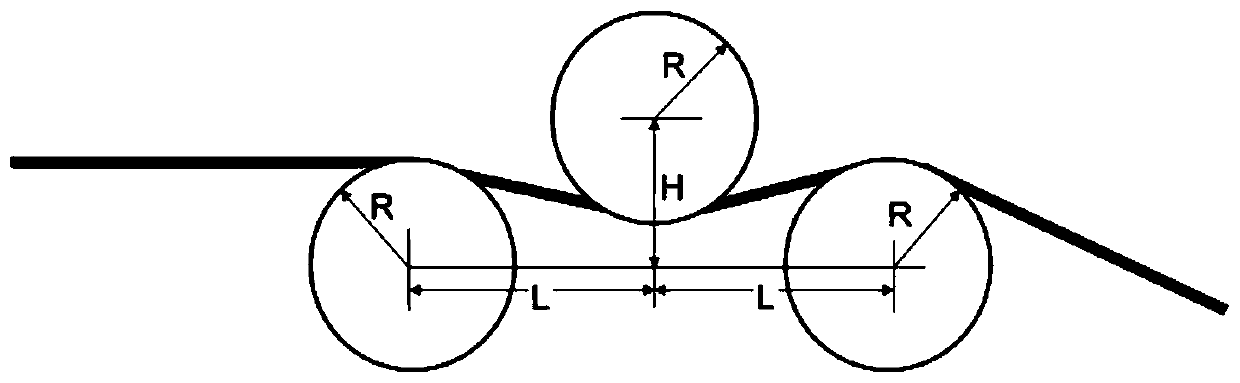

[0028] Step 2: Pass the cold-rolled strip through three consecutive guide rolls with ultrasonic vibration function. The three ultrasonic guide rollers have a diameter of 150mm.

[0029] Step 3: The vibration frequency of the ultrasonic guide roller 1 is set to 200KHZ, the vibration frequency of the ultrasonic guide roller 2 is set to 500KHZ, and the vibration frequency of the ultrasonic guide roller 3 is set to 300KHZ.

[0030] Step 4: Crimp the product to produce a high-quality aluminum strip with low residual stress. After testing, the residual stress inside the produ...

Embodiment 2

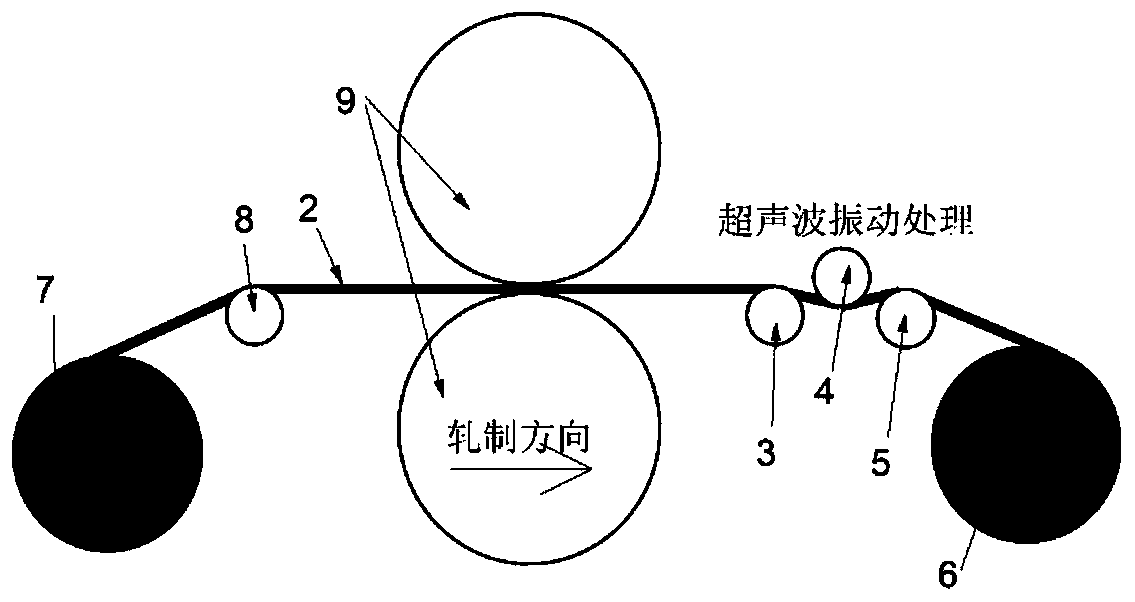

[0032] To produce low residual stress AA1050 aluminum alloy foil with a thickness of 25 μm, the steps are as follows:

[0033] The first step: using aluminum alloy AA6061 medium and heavy plate as raw material, the initial thickness of the rolled piece is 30 μm, and the aluminum alloy is subjected to single-stand cold rolling, the thickness of the cold-rolled product is 25 μm, and the residual stress inside the rolled piece is 50 MPa.

[0034] Step 2: Pass the cold-rolled strip through three consecutive guide rolls with ultrasonic vibration function. The three ultrasonic guiding rollers have a diameter of 100mm.

[0035] Step 3: The vibration frequency of the ultrasonic guide roller 1 is set to 80KHZ, the vibration frequency of the ultrasonic guide roller 2 is set to 100KHZ, and the vibration frequency of the ultrasonic guide roller 3 is set to 80KHZ.

[0036] Step 4: Crimp the product to produce a high-quality aluminum alloy foil with low residual stress. After testing, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com