A CMT Arc Surface Cladding Method Based on Database System

A technology of database and substrate surface, applied in metal material coating process, coating, etc., can solve the problems of cladding metal accumulation cladding efficiency, poor cladding metal spreadability, constant lap width, etc., and achieve residual stress value Low, excellent cladding effect, narrow heat-affected zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

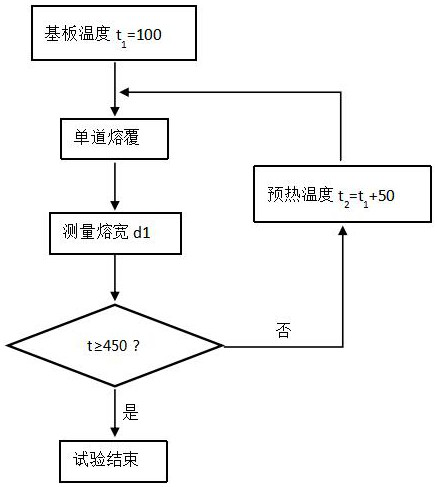

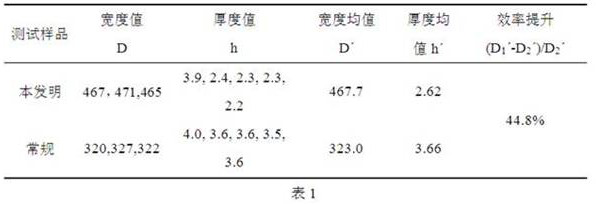

[0040] This embodiment proposes a CMT arc surface cladding method based on a database system, such as figure 1 shown, including the following steps:

[0041] Step 1: Establish a cladding database of temperature-melting width-lap width;

[0042] Step 2: Use the established cladding database of temperature-melting width-lap width to carry out actual CMT arc surface cladding on the substrate;

[0043] The operation of the step 1 specifically includes:

[0044] Step 1.1: Grinding or turning the surface of the substrate to clean and remove the dirt on the surface of the substrate;

[0045] Step 1.2: Use a heating device to preheat the substrate after removing surface contamination to a temperature t 1 ;

[0046] Step 1.3: CMT arc is used to perform single-pass cladding on the surface of the substrate, and the parameters during the single-pass cladding operation are: wire feeding speed WFS =5.0m / min, CMT non-synthetic adjustment of arcing current I boost =320A, short circuit c...

Embodiment 2

[0053] In this embodiment, on the basis of the above-mentioned embodiment 1, in order to better realize the present invention, further, the preheating temperature range in the step 1.2 is 100-450°C, and the interval between two adjacent groups of preheating temperatures d is 50°C, and the temperature fluctuation is ±5°C.

[0054] Other parts of this embodiment are the same as those of Embodiment 1 above, so details are not repeated here.

Embodiment 3

[0056] In this embodiment, on the basis of any one of the above-mentioned embodiments 1-2, in order to better realize the present invention, further, in the step 1.1, after cleaning and removing the dirt on the surface of the substrate, anhydrous Ethanol for cleaning.

[0057] In the step 1.2, after preheating to temperature t1, keep preheating for at least 3s before the welding torch starts arcing, and then turn off the preheating device.

[0058] Further, in the step 1.3, during the single pass cladding on the surface of the substrate using the CMT arc, the welding torch and the cladding direction always maintain an inclination angle of 75°.

[0059] Further, the method for counting the width of the cladding layer in the step 1.4 is to measure the width of the single-pass cladding layer at the arc-starting end 1cm, the 1 / 2 cladding layer length and the arc-ending end 1cm The width of the three positions is averaged After the value is used as the melting width data d at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com