Preparation method and application of high adsorption performance water supply plant residual mud non-sintered ceramsite

A water supply plant, high adsorption technology, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of low adsorption capacity of ceramsite residue in water supply plants and reduce residual sludge in water supply plants Iron-aluminum activity, preparation of non-fired ceramsite and other issues, to achieve the effect of low equipment investment cost and operating cost, high porosity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

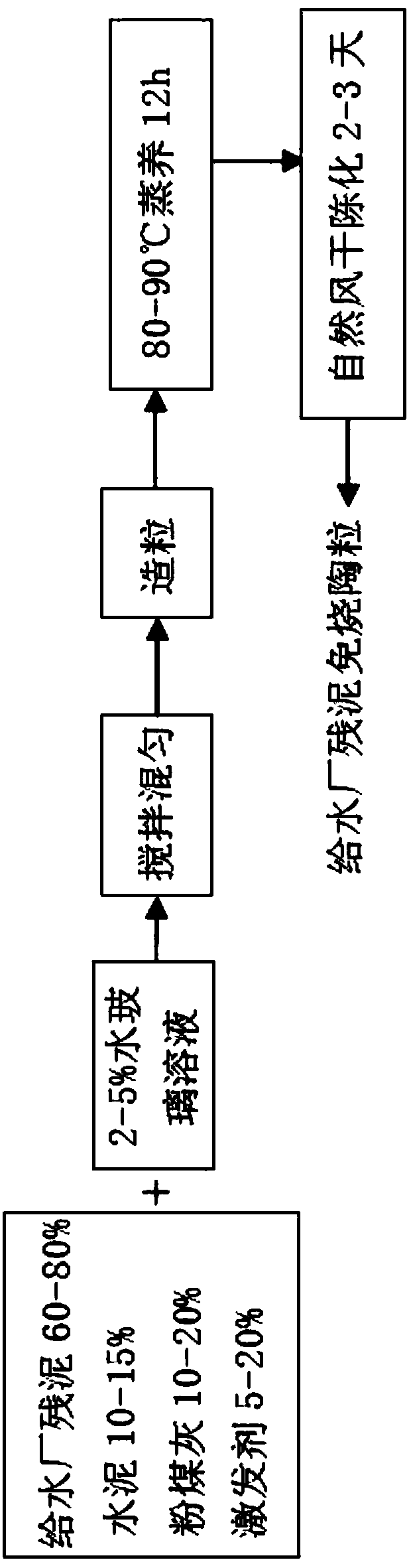

[0030] refer to Figure 1-6 , the specific implementation method adopts the following technical scheme: a kind of preparation method of unfired ceramsite of residual mud of a water supply plant with high adsorption performance, and its steps are:

[0031] (1) Raw material pretreatment: Grind the residual mud of the water supply plant, cement, fly ash and activator respectively, and mix them according to a certain mass ratio. %, activator 2%-6%, fly ash 10%-20%;

[0032] (2) Granulation: Add 32-35ml of an aqueous solution containing 2%-5% water glass to the homogeneously mixed raw materials in step (1), stir and put it into a pelletizer to granulate to obtain a spherical shape with a particle diameter of 5-10mm Ceramsite raw materials;

[0033] (3) Steaming: place the ceramsite raw meal at room temperature for 2-3 hours, and then put it in a sterilizing pot at 70-90°C for 10-14 hours;

[0034] (4) Aging: The steamed ceramsite is naturally air-dried and aged at room temperatu...

Embodiment 1

[0038] Example 1: A preparation method of non-fired ceramsite with high adsorption performance for water supply plant residual mud: the main raw material is the residual mud of a water supply plant in Changsha City. The residual mud is mainly composed of Si, Al and Fe, and its main components are shown in the table 1.

[0039] Table 1 Main component content of water supply plant residual mud and unfired ceramsite

[0040]

[0041]After drying, crushing and grinding the residual mud of the water supply plant to 100 meshes, mix it with activator, fly ash and ordinary Portland cement in a certain mass ratio, and add 2%-5% of Put the water glass solution (binder) into the granulator to prepare unfired ceramsite raw meal, place the raw meal at room temperature for 2-3 hours, then place it in a 70-90°C sterilizing pot for 12 hours, and then Put it in a drying oven to air-dry and age for 24 hours. The unfired ceramsite prepared from the residual mud of the water supply plant has...

Embodiment 2

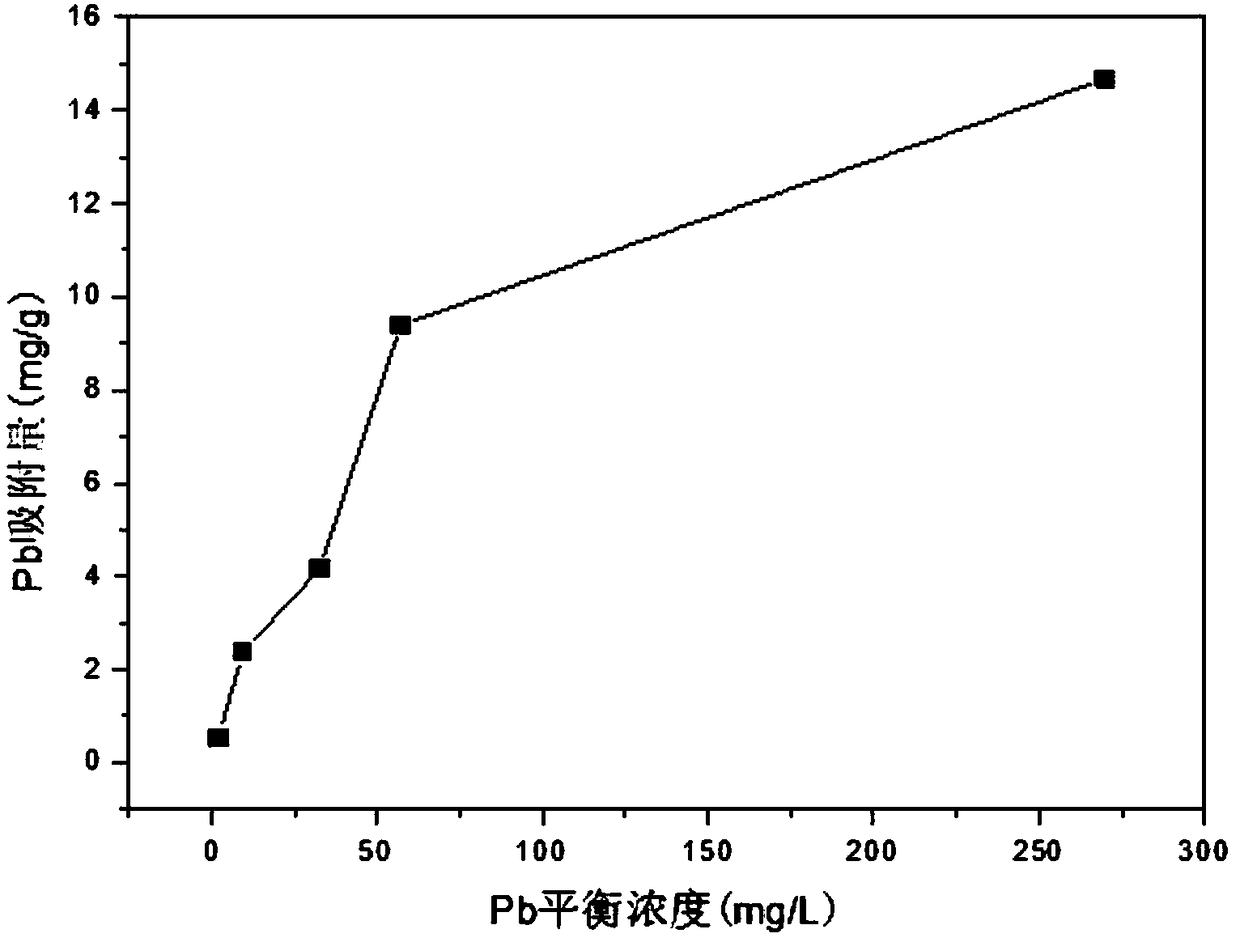

[0042] Example 2: Use of a high-adsorption performance unburned ceramsite for residual mud in water supply plants: The adsorption capacity of unburned ceramsite for residual mud in water supply plants to lead:

[0043] Weigh 4 pieces (total mass is about 0.5g) of the unfired ceramsite in the water supply plant in Example 1 into a 50mL centrifuge tube, and add 30mL Pb solutions with different concentrations of pH 5.00, wherein the KCl concentration is 0.01mol / L. The sample was shaken in a constant temperature shaking box at 25°C and 150rpm for 8h (the adsorption equilibrium time was determined to be 8h by the adsorption kinetic experiment), and then centrifuged at 4500g for 15min, and the supernatant was taken to measure the lead concentration. According to the change of the lead concentration in the initial aqueous solution and the supernatant, the equilibrium adsorption amount of unfired ceramsite to lead was calculated. The adsorption isotherm data of unfired ceramsite on le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com