Preparation method of a wear-resistant and high-strength self-lubricating electrical contact material

An electric contact material and self-lubricating technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of short service life and poor wear resistance of materials, achieve enhanced wear resistance, self-lubrication performance, and durability The effect of grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

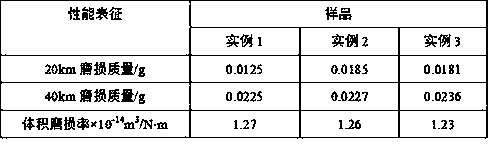

Examples

example 1

[0018] According to the mass ratio of 1:15, ferric sulfate and deionized water were stirred and mixed, and the pH was adjusted to 8.5 with a mass fraction of 10% sodium hydroxide solution, and the mixture was left to age for 6 hours to obtain the mixed solution and weighed 45 parts by weight. Put 3 parts of mixed solution, 3 parts of sodium dihydrogen phosphate and 3 parts of ferrous sulfate in a beaker, stir and mix and add dropwise 1% sulfuric acid solution to pH to 5.5, stir and mix and heat to boiling, heat preservation treatment for 2h, static Cool to room temperature, centrifuge at 1500r / min and collect the lower precipitate, and vacuum freeze-dry to obtain modified particles; according to the mass ratio of 1:10, add the modified particles to 200 mesh molybdenum disulfide powder to obtain mixed particles and Place in a quartz tube, seal the tube and evacuate it to 15Pa, heat up the tube to 450 °C at 5 °C / min, pass argon to remove the air and keep it warm for 2 hours, let ...

example 2

[0020] According to the mass ratio of 1:15, ferric sulfate and deionized water were stirred and mixed, and the pH was adjusted to 8.5 with a mass fraction of 10% sodium hydroxide solution, and left to age for 7 hours to obtain the mixed solution and weigh 47 4 parts of mixed solution, 4 parts of sodium dihydrogen phosphate and 4 parts of ferrous sulfate were placed in a beaker, stirred and mixed and added dropwise with a mass fraction of 1% sulfuric acid solution to pH to 5.5, stirred and mixed and heated to boiling, after heat preservation for 3 hours, static Cool to room temperature, centrifuge at 1750r / min and collect the lower precipitate, and vacuum freeze-dry to obtain modified particles; according to the mass ratio of 1:10, the modified particles are added to 200 mesh molybdenum disulfide powder to obtain mixed particles and Put it in a quartz tube, seal the quartz tube and evacuate to 17Pa, heat the quartz tube to 475 °C at 5 °C / min, pass argon to remove the air and kee...

example 3

[0022] According to the mass ratio of 1:15, ferric sulfate and deionized water were stirred and mixed, and the pH was adjusted to 8.5 with a mass fraction of 10% sodium hydroxide solution, and left to age for 8 hours to obtain the mixed solution and weighed 50% by weight. 5 parts of mixed solution, 5 parts of sodium dihydrogen phosphate and 5 parts of ferrous sulfate were placed in a beaker, stirred and mixed and added dropwise with a mass fraction of 1% sulfuric acid solution until the pH reached 5.5, stirred and mixed and heated to boiling, after heat preservation for 3 hours, static Cool to room temperature, centrifuge at 2000r / min and collect the lower precipitate, and vacuum freeze-dry to obtain modified particles; according to the mass ratio of 1:10, add the modified particles to 200 mesh molybdenum disulfide powder to obtain mixed particles and Place in a quartz tube, seal the quartz tube and evacuate to 20Pa, heat up the quartz tube to 500 °C at 5 °C / min, pass argon gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com