Bag-type dust collector of flour mill

A technology of bag dust collector and pulverizer, which is applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve problems such as impacting dust bag, damage of dust bag, and large gas flow rate at the air inlet, etc., to achieve extended Long service life, good cleaning effect and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

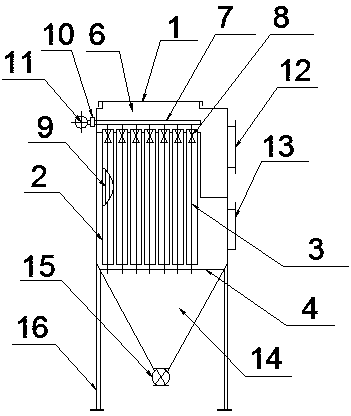

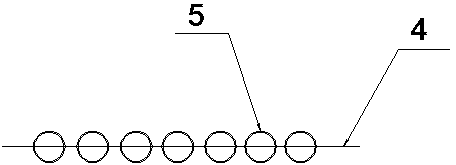

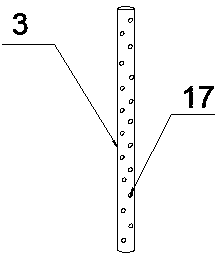

[0018] Such as Figure 1-3 As shown, the present invention provides a bag filter for pulverizers, which includes a main body of a dust removal device. A cleaning room is arranged on the main body of the dust removal device. The bottom of the tube is provided with an annular ejector, the two ends of the filter bag are provided with ring bones, the filter bag is provided with a bag cage, the filter bag is provided with a first nozzle, and the first nozzle is provided with a dust cleaning hole , the bottom of the filter bag is provided with a fixed shaft, the bottom of the filter bag is provided with a dust removal box, the bottom of the dust removal box is provided with a dust discharge valve, the bottom of the main body of the dust removal device is provided with a bracket, and one side of the main body of the dust removal device is provided with an electromagnetic pulse valve. One side of the electromagnetic pulse valve is provided with a gas storage tank, the other side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com