Nickel cobalt lithium manganate ternary polymer battery anode waste material recovery method

A technology of nickel-cobalt lithium manganese oxide and ternary polymer, which is applied in the field of positive electrode waste recycling of nickel-cobalt lithium manganese oxide ternary polymer battery, can solve problems such as environmental pollution and waste of resources, and achieve simple process, low cost, Wide recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

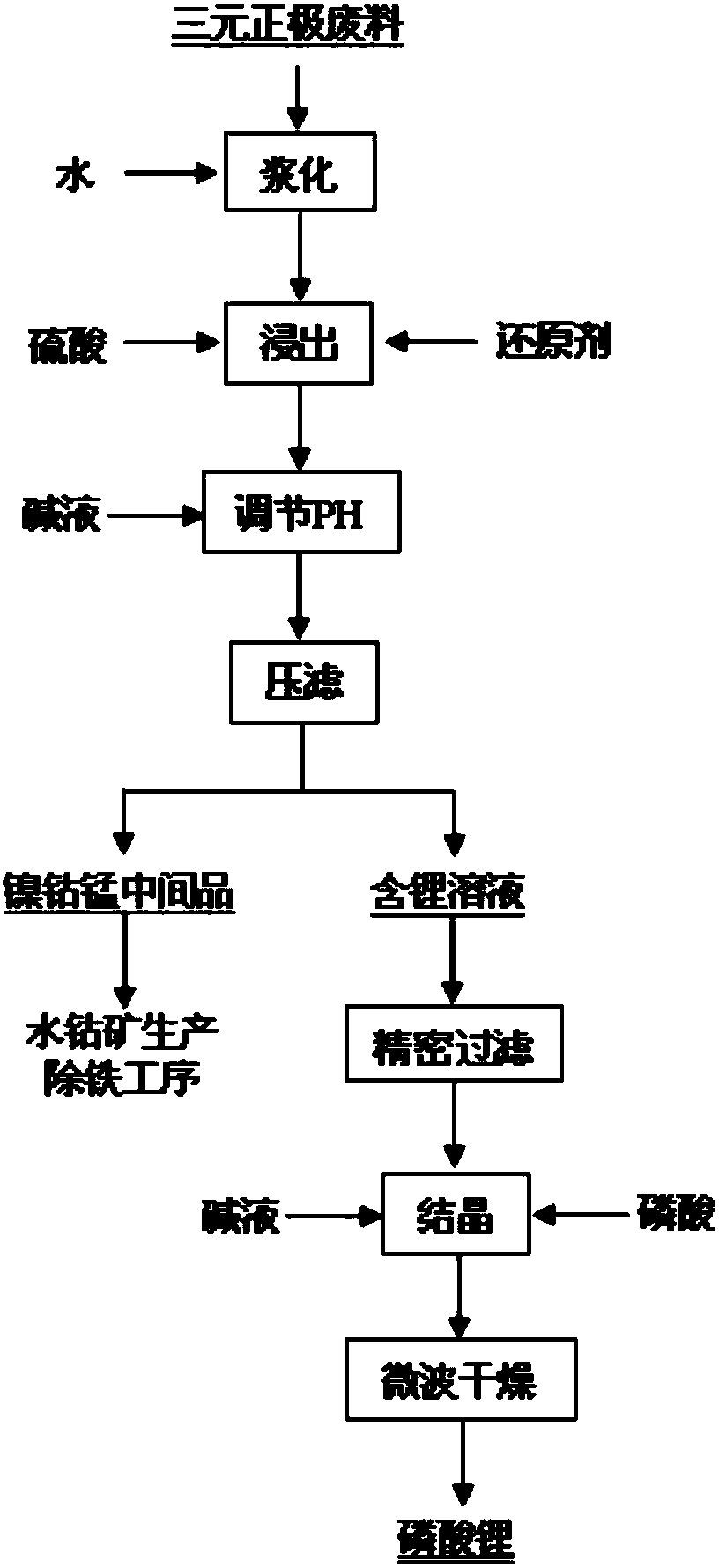

Image

Examples

Embodiment 1

[0023] (1) The waste cathode material is slurried with water at 10:1; the reaction temperature is 90°C; the stirring speed is 65rpm; the reaction time is 2h; the reaction process uses H 2 SO 4 Maintain the pH of the solution at 1.0, add Na after 45 minutes of reaction 2 SO 3 , the addition coefficient is 1.4.

[0024] (2) After all the waste materials are completely dissolved, add NaOH to adjust the pH of the solution to 9.0, and continue to stir for 30 minutes. The precipitate is filtered through a plate and frame, and the nickel-cobalt-manganese intermediate product obtained by the filter is used for the adjustment of the iron removal process in the production process of water cobalt ore pH value.

[0025] (3) After the filtered lithium hydroxide solution is further purified by the polymer PE microporous membrane, slowly add 1mol / L of H 3 PO 4 And stir, the solution temperature is 72°C, use liquid caustic soda to control the final pH of the solution to 10, continue to s...

Embodiment 2

[0027] (1) The waste cathode material is slurried with water at 11:1; the reaction temperature is 85°C; the stirring speed is 70rpm; the reaction time is 2.2h; the reaction process uses H 2 SO 4 Keep the pH of the solution at 1.0, and add Na after 50 minutes of reaction 2 S 2 o 3 , the addition coefficient is 1.3.

[0028] (2) After all the waste materials are completely dissolved, add NaOH to adjust the pH of the solution to 9.5, and continue to stir for 30 minutes. The sediment is filtered through a plate and frame, and the nickel-cobalt-manganese intermediate product obtained by the filter is used for the adjustment of the iron removal process in the production process of water cobalt ore pH value.

[0029] (3) After the filtered lithium hydroxide solution is further purified by the polymer PE microporous membrane, slowly add 1.2mol / L of H 3 PO 4 And stir, the solution temperature is 70°C, use liquid caustic soda to control the final pH of the solution to 10, continue...

Embodiment 3

[0031] (1) The waste cathode material is slurried with water at 10:1; the reaction temperature is 95°C; the stirring speed is 75rpm; the reaction time is 2h; the reaction process uses H 2 SO 4 Keep the pH of the solution at 1.0, and add Na after 40 minutes of reaction 2 S 2 o 5 , the addition coefficient is 1.3.

[0032](2) After all the waste materials are completely dissolved, add NaOH to adjust the pH of the solution to 9.0, and continue to stir for 45 minutes. The precipitate is filtered through a plate and frame, and the nickel-cobalt-manganese intermediate product obtained by the filter is used for the adjustment of the iron removal process in the water cobalt ore production process. pH value.

[0033] (3) After the filtered lithium hydroxide solution is further purified by the polymer PE microporous membrane, slowly add 1.4mol / L of H 3 PO 4 And stir, the solution temperature is 80°C, use liquid caustic soda to control the final pH of the solution to 10, continue t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com