Sanitary dental bur and manufacturing method thereof

A technology of dentistry and burs, which is applied in dentistry, dental tools, medical science, etc., can solve the problems of high mobility, many dental outpatients, high bur usage rate, and high turnover rate, so as to reduce injuries, reduce labor intensity, The effect of fast cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

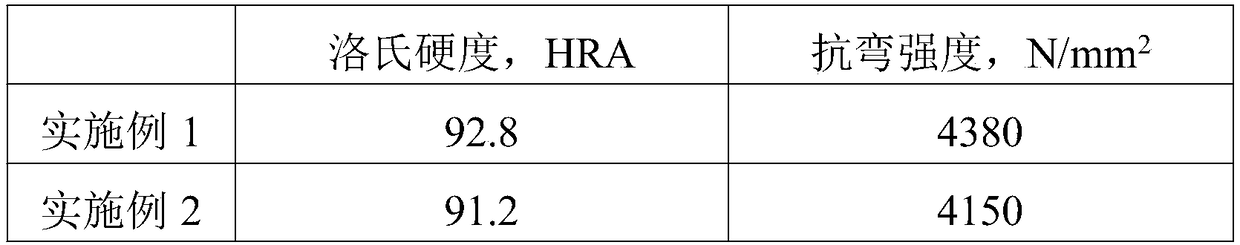

Embodiment 1

[0057] The raw material formula of tungsten steel material is as follows:

[0058] 50 kg of cobalt;

[0059] Chromium dicarbide 1.5 kg;

[0060] 1 kg of vanadium carbide;

[0061] 1 kg of tantalum carbide;

[0064] Tungsten carbide 444.5 kg.

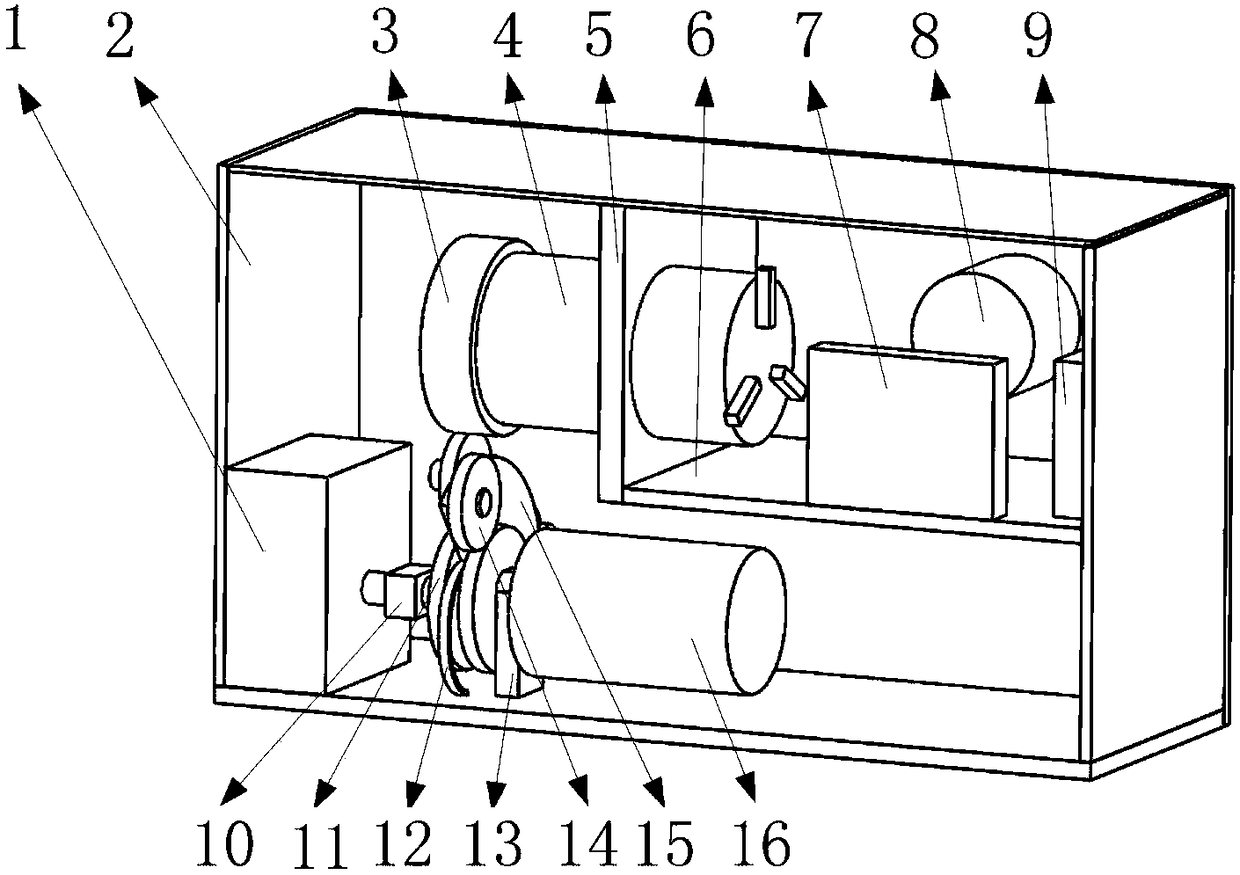

[0065] figure 2 It is the production flow chart of the base material of sanitary dental bur.

[0066] (1) Place the above-mentioned tungsten steel material raw material in a ball mill, add 150 liters of anhydrous ethanol, use anhydrous ethanol as a grinding medium, and wet-mill and mix for 48 hours.

[0067] (2) Put it into a vacuum dryer, then add 50 kg of Kunlun brand No. 56 fully refined granular paraffin, and dry it for 5 hours while stirring.

[0068] (3) Low-temperature sintering: The sieved material is sent into the mold, pressed into a preliminary blank, the pressing pressure is 0.8MPa, and then sent into the sintering furnace, the pressure is set to 5MPa, th...

Embodiment 2

[0072] The raw material formula of tungsten steel material is as follows:

[0073] 50 kg of cobalt;

[0074] Chromium dicarbide 1.5 kg;

[0075] 2 kg of vanadium carbide;

[0077] Silicon nitride 1 kg;

[0078] Tungsten carbide 444.5 kg.

[0079] The preparation method is exactly the same as that of Example 1.

Embodiment 3

[0081] The raw material formula of tungsten steel material is as follows:

[0082] 50 kg of cobalt;

[0083] Chromium dicarbide 1.5 kg;

[0084] 2 kg of tantalum carbide;

[0085] Titanium nitride 1 kg;

[0086] Silicon nitride 1 kg;

[0087] Tungsten carbide 444.5 kg.

[0088] The preparation method is exactly the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com