Preparation method of mullet protein source antioxidant peptide

An antioxidant peptide and protein source technology, applied in the direction of peptides, anti-toxins, fermentation, etc., to achieve the effect of high nutritional value, easy implementation, and increased added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] 1), raw material pretreatment:

[0067] Wash the fresh mullet with water, remove the head, tail and viscera, use a high-speed tissue homogenizer to grind the fish into surimi, freeze-dry and crush (dry to constant weight at -80°C) and pass through an 80-mesh sieve,- Store in refrigerator at 18°C.

[0068] 2) Degreasing mullet meat: mix freeze-dried fish powder and ethyl acetate according to the ratio of material to liquid (1g:2ml), stir continuously for 120min in a water bath at 55°C, and put the filter cake (minced fish after degreasing) into In a fume hood, freeze-dry (-80°C to constant weight) after ethyl acetate volatilizes completely, crush through an 80-mesh sieve to obtain defatted mullet protein powder (GM), and store in a refrigerator at -18°C.

[0069] 3), mullet protein hydrolysis:

[0070] The hydrolysis conditions of GM are: solid-to-liquid ratio 1:20 (mass ratio), neutral protease as hydrolase, temperature 50°C, pH 7.0, time 5h, and enzyme amount 5.0U / mg...

Embodiment 2

[0073] The raw material pretreatment of step 1) and the degreasing of mullet meat in step 2) are the same as in Example 1.

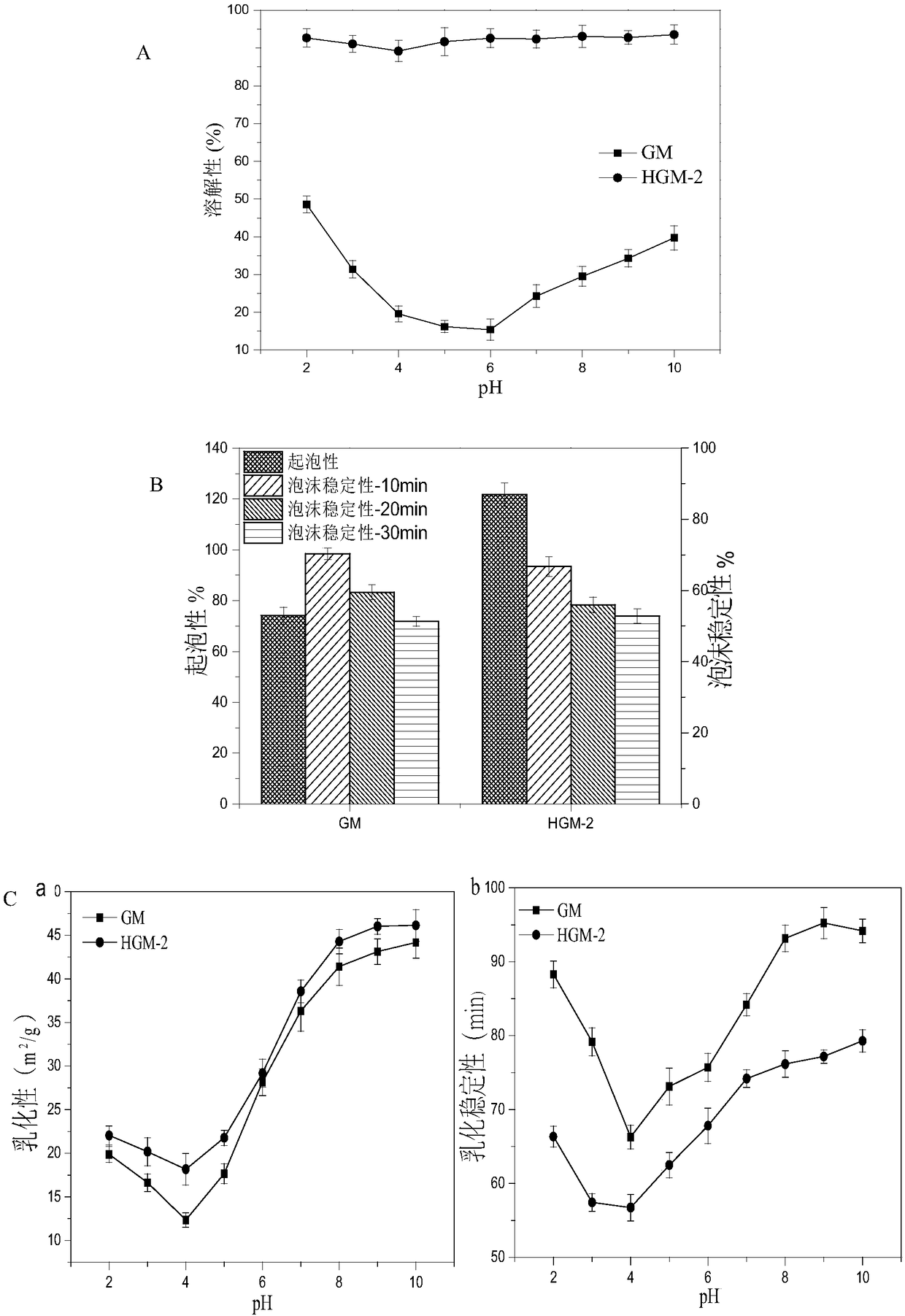

[0074] Mullet protein hydrolysis: The hydrolysis conditions of GM are: solid-liquid ratio 1:20, neutral protease as hydrolytic enzyme, temperature 51°C, pH 7.3, time 3.5h, and enzyme amount 5.8U / mg, to maintain the hydrolysis process The pH and temperature in the medium were stable. The mullet protein hydrolyzate obtained under these conditions was inactivated in a 95°C water bath for 15 minutes, centrifuged at 10,000 r / min for 10 minutes, and the supernatant was freeze-dried to obtain crude antioxidant peptide (HGM-2). The DPPH free radical scavenging rate of HGM-2 (concentration 1 mg / ml) was measured to be 60.19±0.57%.

[0075] The DPPH free radical scavenging rate, superoxide anion free radical scavenging rate, hydroxyl free radical scavenging rate, reducing power, ferrous ion chelation rate and anti-lipid peroxidation ability of the HGM-2 obtained by...

Embodiment 3

[0077] The raw material pretreatment of step 1) and the degreasing of mullet meat in step 2) are the same as in Example 1.

[0078] Mullet protein hydrolysis: The hydrolysis conditions of GM are: solid-liquid ratio 1:20, neutral protease is used as the hydrolytic enzyme, the enzymatic hydrolysis conditions are: temperature 50°C, pH 7.0, time 4h, and the amount of enzyme added 6.5U / mg, Keep the pH and temperature stable during the hydrolysis process. The mullet protein hydrolyzate obtained under these conditions was inactivated in a 95°C water bath for 15 minutes, centrifuged at 10,000 r / min for 10 minutes, and the supernatant was freeze-dried to obtain crude antioxidant peptides (HGM). . The DPPH free radical scavenging rate of HGM (concentration 1 mg / ml) was measured to be 54.57±1.26%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com