Superamphiphobic composites and their applications as inhibitors, lubricants and reservoir protectants in water-based drilling fluids

A water-based drilling fluid and composite material technology, applied in the field of oil and gas drilling, can solve the problems of difficult large-scale application, complex synthesis process, poor high temperature resistance, etc., and achieve low toxicity, strong hydrophobicity, strong resistance and viscosity reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

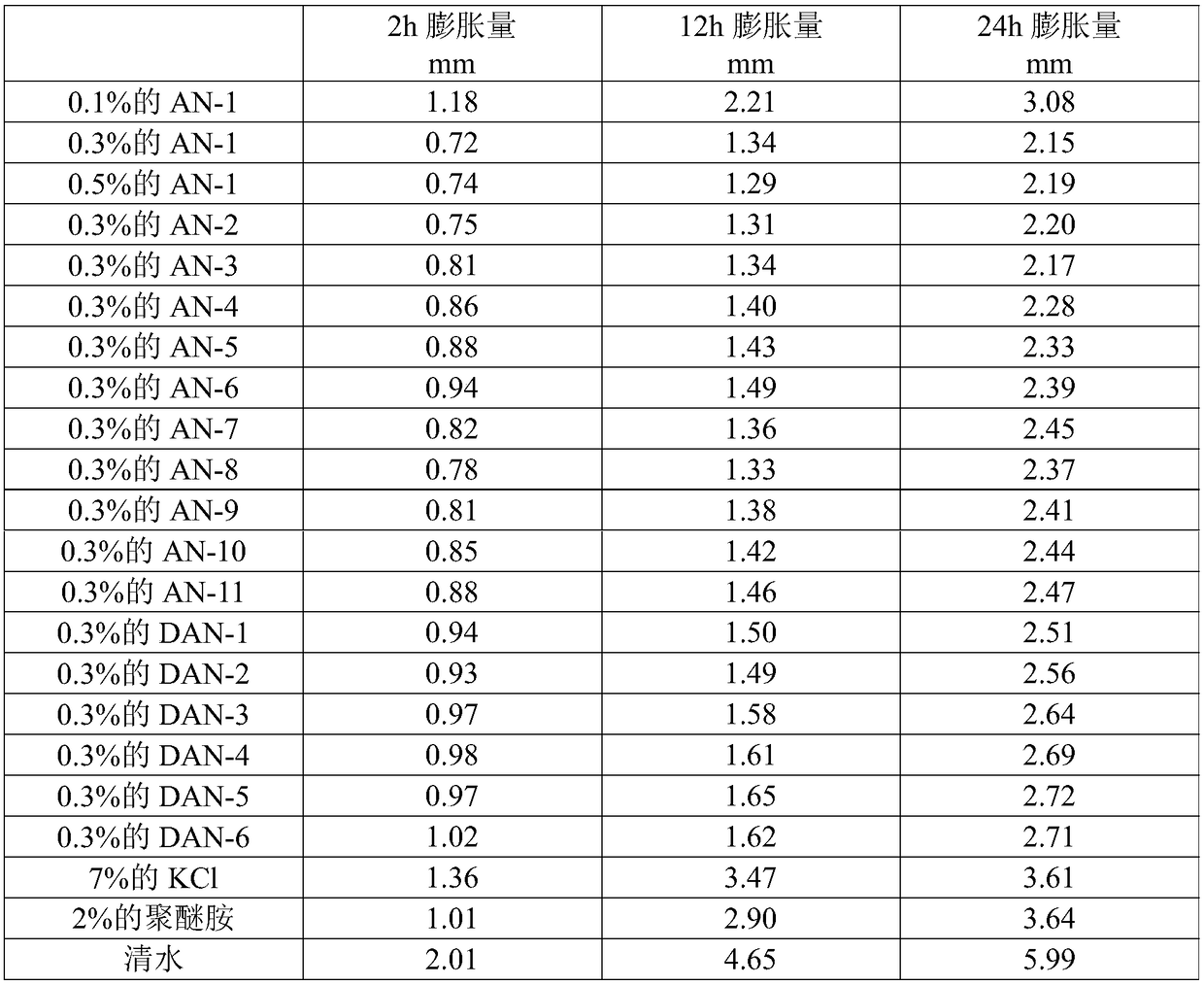

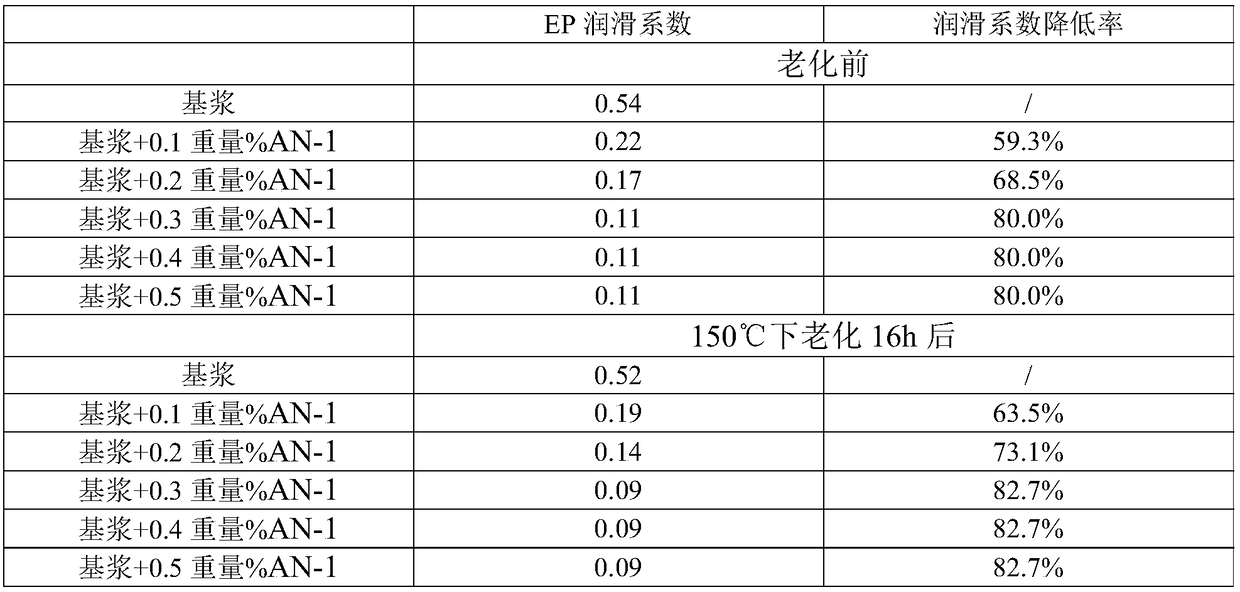

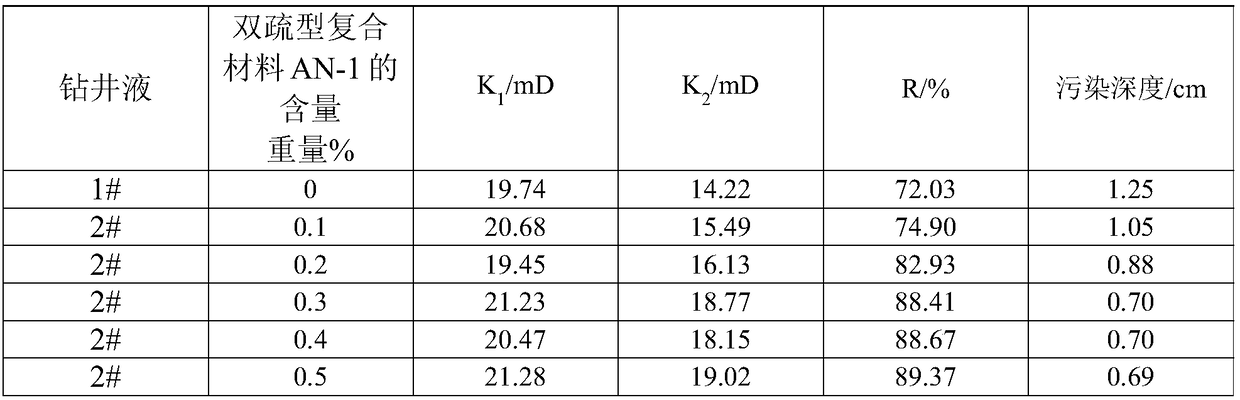

Examples

preparation example Construction

[0014] One aspect of the present invention provides a method for preparing an amphobic composite material, the method comprising:

[0015] Under alkaline conditions, in a mixed solvent of alcohol and water, nano-TiO 2 and nano-SiO 2 Perform the first mixing to obtain nano-TiO 2 and nano-SiO 2 The dispersion liquid; Then the fluorine-containing silicon coupling agent is introduced into the nano-TiO 2 and nano-SiO 2 in the dispersion liquid and carry out the second mixing;

[0016] Among them, TiO 2 , SiO 2 The molar ratio of the fluorine-containing silicon coupling agent is 1:0.5-5:0.01-0.5, and the nano-TiO 2 The particle size is 50-500nm, the nano-SiO 2 The particle size is 50-500nm.

[0017] The amphiphobic composite material prepared by the method of the present invention can be used as an amphiphobic inhibitor, a lubricant, and an oil and gas layer protection agent in water-based drilling fluids. A layer of adsorption layer with hydrophobic and oleophobic propert...

Embodiment 1

[0039] This example is used to illustrate the amphobic composite material of the present invention and its preparation method.

[0040] TiO with a total weight of 5 g 2 Nanoparticles (TiO with a particle size of 100nm 2 nanospheres) and SiO 2 Nanoparticles (SiO with a particle size of 100nm 2 nanospheres) (wherein, TiO 2 and SiO 2 molar ratio of 1:1) was added to 50mL of ethanol and water mixed solvent (ethanol / water volume ratio of 1:2), and the pH value of the system was adjusted to 8 with ammonia water, and then ultrasonically dispersed at 25°C for 20min to obtain Dispersion liquid; Then dodecafluoroheptyltrimethoxysilane (its consumption makes TiO 2 The molar ratio of dodecafluoroheptyltrimethoxysilane to dodecafluoroheptyltrimethoxysilane is 1:0.1) was added to the dispersion, and stirred at 500rpm at 60°C for 12h, the resulting product was centrifuged, the solid phase was washed with water, and heated at 80°C Under drying, the amphiphobic composite material AN-1 ca...

Embodiment 2

[0042] This example is used to illustrate the amphobic composite material of the present invention and its preparation method.

[0043] TiO with a total weight of 5 g 2 Nanoparticles (TiO with a particle size of 100nm 2 nanospheres) and SiO 2 Nanoparticles (SiO with a particle size of 100nm 2 nanospheres) (wherein, TiO 2 and SiO 2 The molar ratio is 1:1.5) was added to 50mL methanol and water mixed solvent (methanol / water volume ratio is 1:5), and the pH value of the system was adjusted to 8.5 with ammonia water, and then ultrasonically dispersed at 25°C for 15min to obtain Dispersion liquid; Then dodecafluoroheptyltrimethoxysilane (its consumption makes TiO 2 The molar ratio of dodecafluoroheptyltrimethoxysilane to dodecafluoroheptyltrimethoxysilane is 1:0.15) was added to the dispersion liquid, and stirred at 450rpm at 65°C for 12h, the obtained product was centrifuged, the solid phase was washed with water, and heated at 80°C Under drying, the amphiphobic composite ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com