Two-component water-based epoxy coating as well as preparation method and application thereof

A water-based epoxy coating, water-based epoxy technology, applied in epoxy resin coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as insufficient stain resistance and poor stability, and achieve anti-fouling effects Good, meet the high cleanliness decoration requirements, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

[0066] Waterborne epoxy resin II described in embodiment 5 is prepared as follows:

[0067] S1. Put 190 parts of epoxy resin E-44 into a four-necked flask, start stirring and slowly raise the temperature to 55°C to stop the temperature rise, add 90 parts of TDI, heat it up to 60°C for 40 minutes, and then add 160 parts of IPDI measured Add 4 drops of bismuth isooctanoate dropwise to a four-necked flask, and slowly raise the temperature to 68±2°C for 90 minutes;

[0068] S2. Add 50 parts of PCL with a molecular weight of 1500-2000 and 30 parts of 1,6-hexanediol into the four-neck flask, and keep warm at 68±2°C for 60 minutes;

[0069] S3. Add 38 parts of DMBA dissolved in DMF, add dropwise 4 drops of stannous octoate and incubate at 68±2°C for 2 hours;

[0070] S4. The content of NCO in the system is detected by the di-n-butylamine method. When the NCO content reaches 3.5-4.0%, add 52 parts of epoxy resin E-51 and keep it at 66-68°C for 60 minutes, then raise the temperature t...

Embodiment 6

[0072] Waterborne epoxy resin III described in embodiment 6 is prepared as follows:

[0073] S1. Put 170 parts of epoxy resin E-44 into a four-necked flask, start stirring and slowly raise the temperature to 55°C to stop the temperature rise, add 70 parts of TDI, heat it up to 60°C for 40 minutes, and then add 150 parts of IPDI measured Add 3 drops of bismuth isooctanoate dropwise to a four-necked flask, and slowly raise the temperature to 68±2°C for 90 minutes;

[0074] S2. Add 40 parts of PCL with a molecular weight of 1500-2000 and 40 parts of 1,6-hexanediol into the four-necked flask, and keep warm at 68±2°C for 60 minutes;

[0075] S3. Add 35 parts of DMBA dissolved in DMF, drop 3 drops of stannous octoate, and keep warm at 68±2°C for 2 hours;

[0076] S4. The content of NCO in the system is detected by the di-n-butylamine method. When the NCO content reaches 1.8-2.45%, add 75 parts of epoxy resin E-51 and keep it at 66-68°C for 60 minutes, then raise the temperature to ...

Embodiment 1

[0079] A two-component waterborne epoxy interior wall paint, its composition and preparation method are as follows:

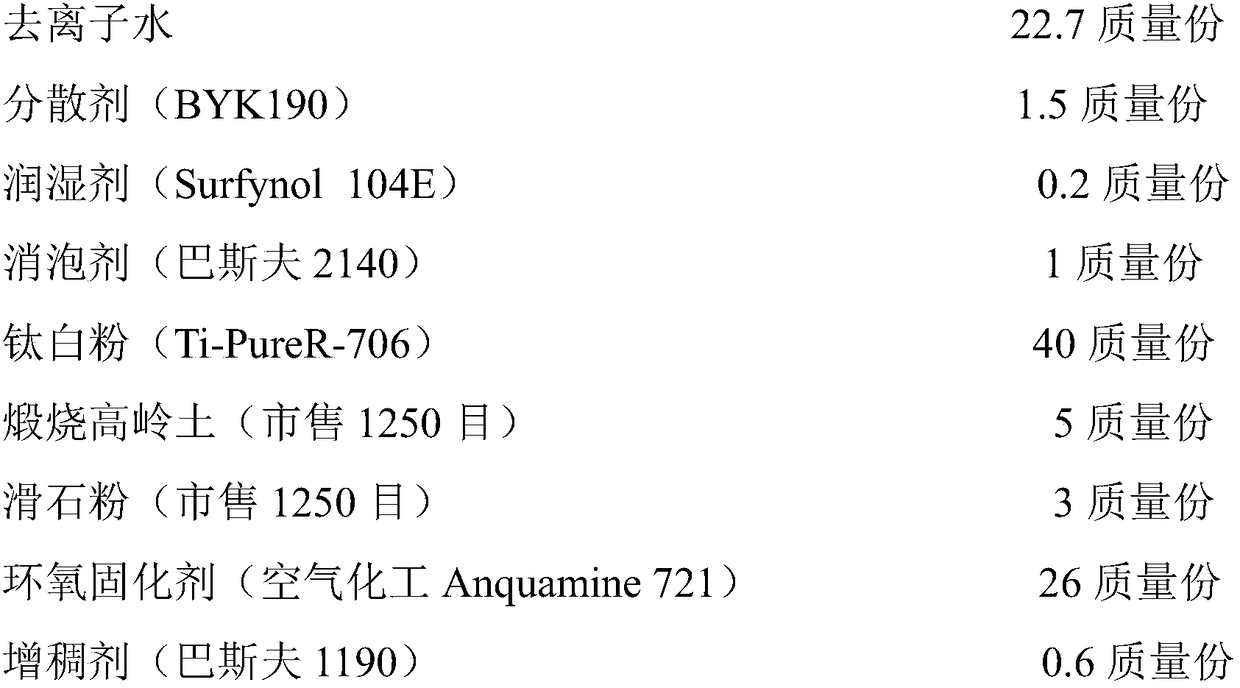

[0080] Component A

[0081]

[0082] Add deionized water into the dispersion tank, add the above materials while stirring, stir and disperse at 1200rpm until the slurry fineness is less than 30um, and disperse normally for 60min.

[0083] Component B

[0084]

[0085] Put each material into the feed kettle in order, adjust the stirring speed to 800rpm, stir and disperse for 30min. Filtering and packaging can get 100 parts by mass of component B of the two-component interior wall paint.

[0086] Before painting, according to the mass ratio of 1:1, mix A and B components evenly, then add about 10% of the total amount of A and B water, and effectively disperse for more than 2 minutes, then you can get shell light, good stain resistance and decorative effect Excellent, two-component water-based epoxy interior wall coating with good scrub resistance and goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com