Glass fiber reinforced PEEK/PES composite material

A composite material and glass fiber technology, which is applied in the field of glass fiber reinforced PEEK/PES composite material and its preparation, to achieve the effects of reducing costs, increasing bending resistance and heat resistance, and increasing the thermal deformation temperature under load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

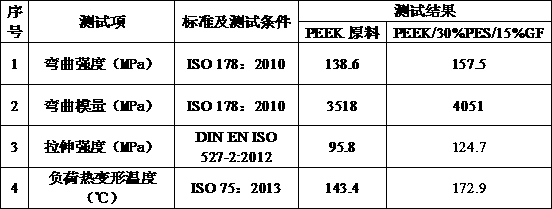

[0024] The PEEK composite material of the present invention is composed of polyethersulfone (PES), polyetheretherketone (PEEK), glass fiber (GF), coupling agent and antioxidant, wherein the mass ratio of each component added is: polyethersulfone (PES) is 30 parts, polyether ether ketone (PEEK) is 55 parts, glass fiber (GF) is 15 parts, coupling agent is 1 part, and antioxidant is 0.3 parts.

[0025] The preparation method of this PEEK composite material comprises the following steps successively:

[0026] Primary drying: PEEK particles and PES powder are dried in a drying oven, the temperature is set at 150°C, and the drying time is 2 hours;

[0027] High-speed mixing: Use a high-speed mixer to mix the high-temperature-resistant chopped glass fiber, coupling agent, antioxidant, PES and PEEK particles according to the formula to make them evenly mixed;

[0028] Extrusion granulation: Use a twin-screw compounding extruder to extrude and granulate the mixed materials. The parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com