Preparation method of adhesion promoter for high refractive index addition type silicone encapsulation adhesive

A technology of adhesion promoter and high refractive index, used in adhesives, polymer adhesive additives, adhesive additives, etc., can solve the problem of poor compatibility between adhesion promoters and encapsulants, complex synthesis process, environmental hazards, etc. problem, to achieve the effect of significant viscosity increase, high refractive index and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this example, the preparation method of the high refractive index adhesion promoter is: add 99.14g of phenyltrimethoxysilane and 8.12g of hexamethyldisiloxane into a 500mL three-port Stir the flask evenly at room temperature, add 0.9g hydrochloric acid and 22.5g deionized water, react at 25°C for 6h, then add 106.35g 3-(2,3-glycidoxy)propyltrimethoxysilane, 12.42 g 3-methacryloyloxypropyltrimethoxysilane, 0.62g boric acid and 8.12g hexamethyldisiloxane, react at 80°C for 1h, and finally remove low boilers to obtain high refractive index viscosity Knot Promoter 1 with a refractive index of 1.526.

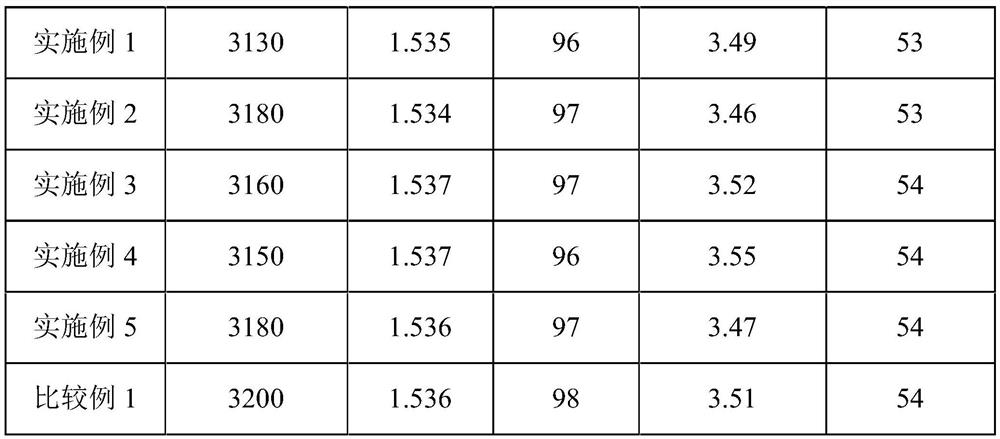

[0020] Preparation of addition-type silicone encapsulant samples: 100 parts by mass of vinylphenyl silicone resin with a vinyl content of 3.6wt%, 20 parts by mass of vinylphenyl silicone oil with a viscosity of 1000mPa·s, 15 parts by mass of active hydrogen content 0.5 wt% of phenyl hydrogen-containing silicone oil, 20 mass parts of phenyl hydrogen-containing silicone resi...

Embodiment 2

[0022] In this example, the preparation method of the high refractive index adhesion promoter is: add 120.18g of phenyltriethoxysilane and 20.26g of trimethylmethoxysilane into a 500mL tank equipped with a thermometer, mechanical stirring and a condensing return tube Stir the three-necked flask evenly at room temperature, add 0.36g of sulfuric acid and 72g of deionized water, react at 40°C for 3h, then add 69.6g of 3-(2,3-glycidoxy)propyltriethoxysilane, 58.09g of 3-methacryloxypropylmethyldimethoxysilane, 3.09g of boric acid and 11g of trimethylmethoxysilane were reacted at 80°C for 1h, and finally the low boilers were removed to obtain high Refractive Index Adhesion Promoter 2 with a refractive index of 1.524.

[0023] The method for preparing the addition-type silicone encapsulant sample in this example is basically the same as that in Example 1, except that the adhesion promoter 1 in Example 1 is changed to adhesion promoter 2. The properties of the samples are shown in T...

Embodiment 3

[0025] In this example, the preparation method of the high refractive index adhesion promoter is: add 122.18g of diphenyldimethoxysilane and 20.04g of divinyltetramethyldisiloxane into the A 500mL three-necked flask with a reflux tube, stirred evenly at room temperature, added 0.72g of acetic acid and 36g of deionized water, reacted at 50°C for 2h, then added 12.32g of 2-(3,4-epoxycyclohexyl)ethyl Trimethoxysilane, 130.69g 3-methacryloxypropyltriethoxysilane, 12.37g boric acid and 7.92g divinyltetramethyldisiloxane, react at 70°C for 3h, and finally remove Low boilers, made of high refractive index adhesion promoter 3, the refractive index is 1.546.

[0026] The method for preparing the addition-type silicone encapsulant sample in this example is basically the same as that in Example 1, except that the adhesion promoter 1 in Example 1 is changed to adhesion promoter 3. The properties of the samples are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com