A molecularly imprinted magnetic nanoparticle that specifically adsorbs bovine hemoglobin

A technology of magnetic nanoparticles and bovine hemoglobin, which is applied in other chemical processes, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of low separation efficiency and complicated sedimentation process, and achieve simple and fast reaction and mild adsorption and separation conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

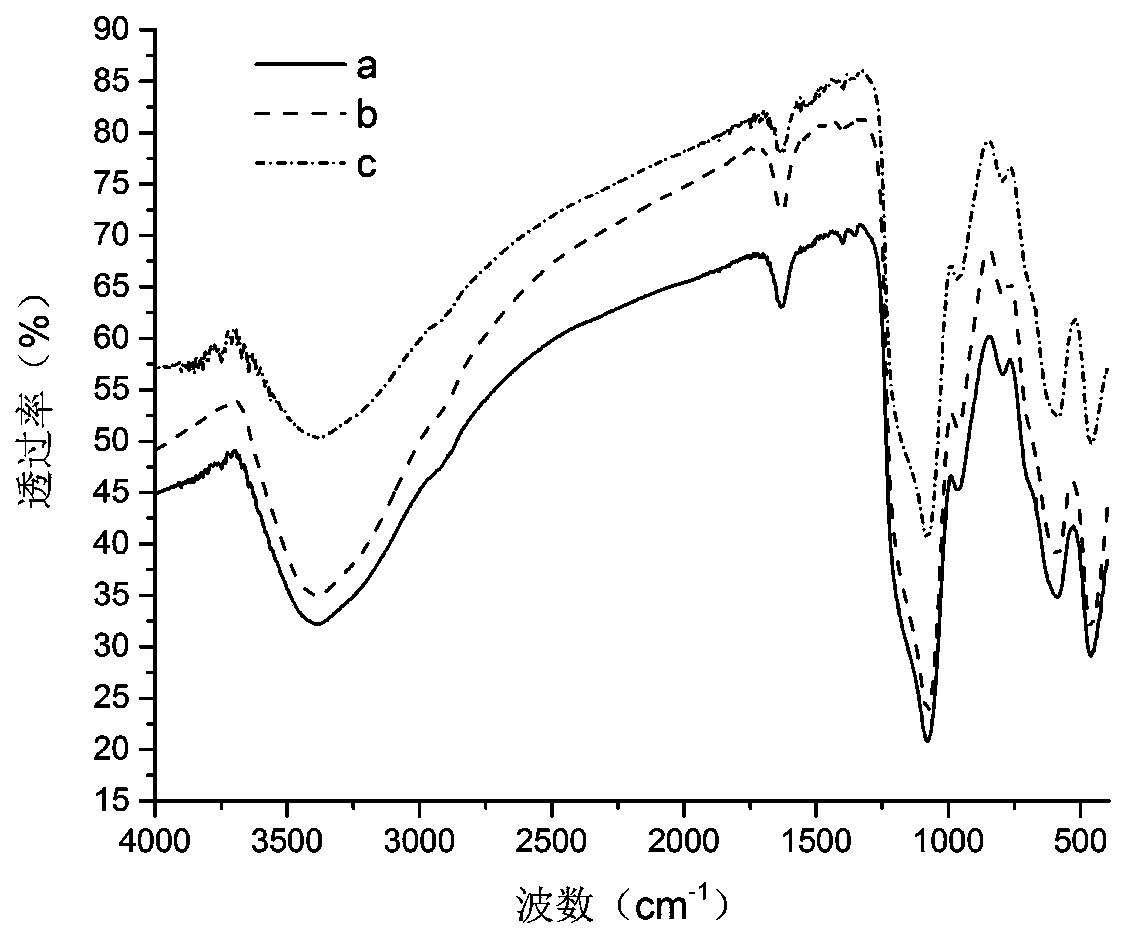

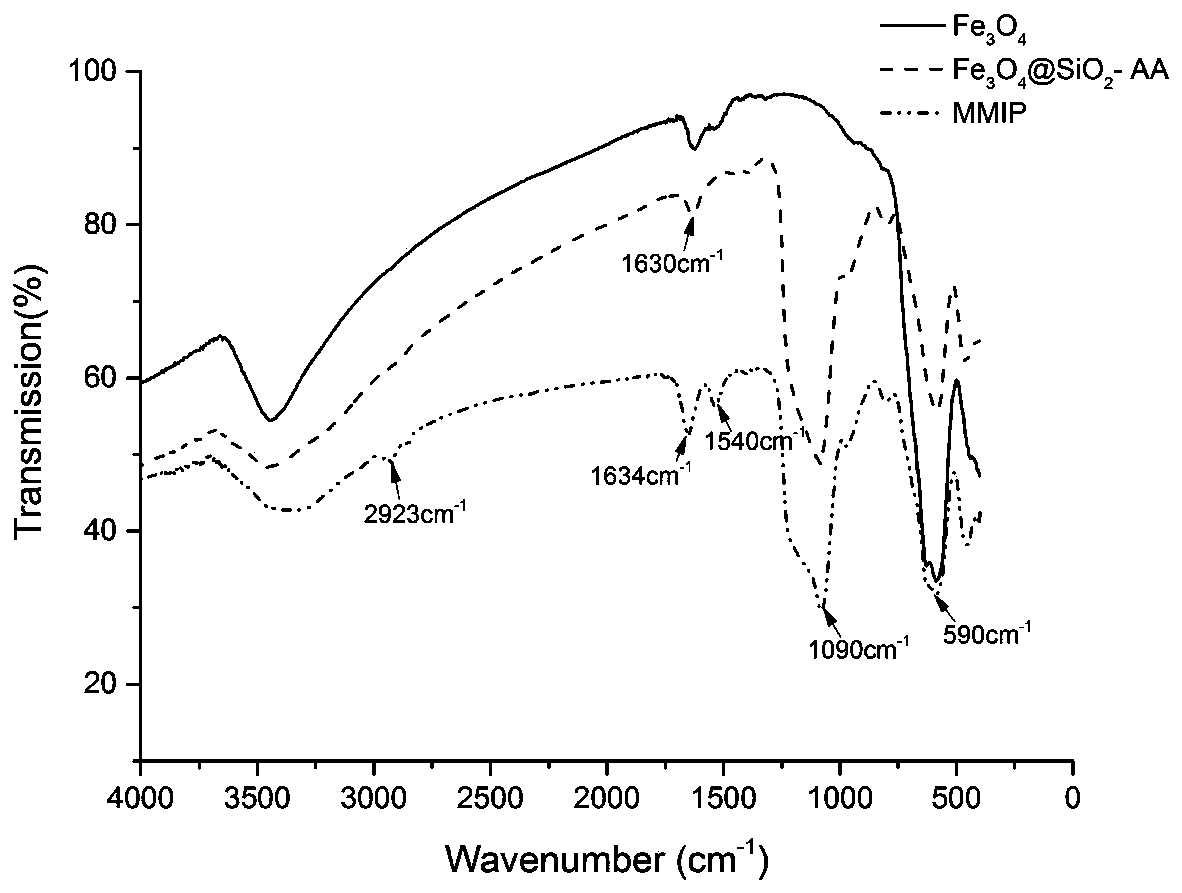

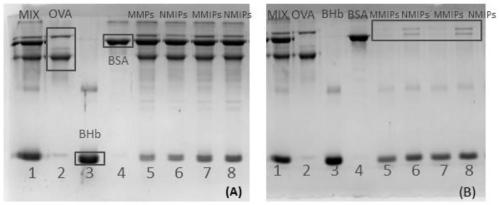

Method used

Image

Examples

Embodiment 1

[0034] Example 1 No Fe 3 o 4 Silanized Acrylic Functionalization of Magnetic Nanoparticles

[0035] Weigh FeSO 4 ·7H 2 O (0.8008g) and FeCl 3 ·6H 2 O (1.1677g) was placed in a four-neck flask, 200mL of deionized water and 40mL of absolute ethanol were added, and nitrogen gas was introduced. The reaction system was placed in a water bath environment at 60° C., and stirred with a mechanical stirrer at a speed of 900 r / min for 0.5 h to remove oxygen in the reaction system. Subsequently, 5 mL of 25% ammonia water was added to make the pH of the system 10-11, and the solution instantly changed from brownish red to black, and the solution was aged for 10 minutes and then vacuum-dried.

[0036] Take 60mg of Fe produced 3 o 4 Particles, sequentially 70 μL functional monomer methacrylic acid (MAA) and 25 mg itaconic acid (IA), 16 mg crosslinker methylenebisacrylamide (N'N-MBA), and 20 mL PBS buffer solution (0.02M, pH7 .00), ultrasonically oscillating and mixing for 10 minutes...

Embodiment 2

[0040] Example 2 No Fe 3 o 4 Acrylic functionalization modification of magnetic nanoparticles

[0041] Weigh FeSO 4 ·7H 2 O (0.8008g) and FeCl 3 ·6H 2 O (1.1677g) was placed in a four-neck flask, 200mL of deionized water and 40mL of absolute ethanol were added, and nitrogen gas was introduced. The reaction system was placed in a water bath environment at 60° C., and stirred with a mechanical stirrer at a speed of 900 r / min for 0.5 h to remove oxygen in the reaction system. Then 5 mL of 25% ammonia water was added to make the pH of the system 10-11, the solution changed from brownish red to black instantly, and the reaction was matured for 10 minutes.

[0042] Lower the temperature of the mature reaction system to 30°C, add 20 mL of 5% TEOS ethanol solution dropwise for silanization modification, keep mechanical stirring at 900r / min, and react for 2 hours to obtain silanization-modified magnetic particles Fe 3 o 4 @SiO 2 . Place the system in an external magnetic fiel...

Embodiment 3

[0048] Weigh FeSO 4 ·7H 2 O (0.8008g) and FeCl 3 ·6H 2 O (1.1677g) was placed in a four-neck flask, 200mL of deionized water and 40mL of absolute ethanol were added, and nitrogen gas was introduced. The reaction system was placed in a water bath environment at 60° C., and stirred with a mechanical stirrer at a speed of 900 r / min for 0.5 h to remove oxygen in the reaction system. Then 5 mL of 25% ammonia water was added to make the pH of the system 10-11, the solution changed from brownish red to black instantly, and the reaction was matured for 10 minutes.

[0049] The temperature of the matured reaction system was lowered to 30° C., 20 mL of 5% TEOS ethanol solution was added dropwise for silanization modification, and mechanical stirring was maintained at 900 r / min for 2 hours of reaction.

[0050] Place the silanized modified reaction solution in an external magnetic field, remove the supernatant reaction solution, wash the magnetic particles several times with deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com