Fungus and algae rotary bio-membrane reactor system based on denitrification and phosphorus removal and application

A biofilm system and rotating biological technology, applied in sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of large excess sludge production, low nitrogen and phosphorus removal efficiency, and large emissions. , to achieve the effect of reducing aeration energy consumption, maximizing benefits and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

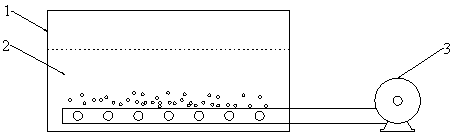

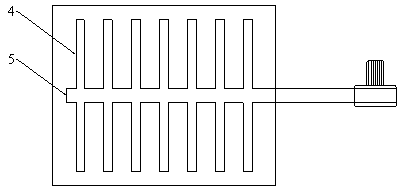

[0047] A biofilm reactor system based on phosphorus and nitrogen removal and its application described in this embodiment mainly includes two parts: an activated sludge system and a conveyor-type rotary algae biofilm system.

[0048] The main body of the activated sludge system is an aeration tank (1), which also includes activated sludge (2) and a blower (3). The aeration main pipe (5) and the aeration branch pipe (4) are located at the bottom of the aeration tank.

[0049] Conveyor belt rotating algae biofilm system includes rotating shaft (7), conveyor belt algae film (12), conveyor belt supporting steel frame (6), conveyor belt scraper (9), conveyor belt motor (11), power conveyor belt (8) and conveyor belt microalgae collection Slot (10).

[0050] The process steps for the application are

[0051] Step 1: Cultivation of Microalgae

[0052] The well-growing microalgae were transferred to the microalgae medium for culture, and cultured in a light shaker with a light inten...

Embodiment 2

[0062] The removal effect of phosphorus in wastewater

[0063] Activate the well-growing chlorella from the slant of the test tube into the BG-11 culture medium, and cultivate it in a light shaker with a rotation speed of 120 rpm, a temperature of 28°C, and a light intensity of 4000 Lux for 7 days to obtain the optical density value Algae liquid with a higher cell density of 0.8, soak the adherent material in the algae liquid and cultivate it under light conditions for 24 hours to make the microalgae cells adhere to the adherent material, obtain municipal wastewater and Activated sludge, transfer municipal wastewater to the aeration tank (1) of the activated sludge system, add the activated sludge at the same time, turn on the blower (3) and set the aeration rate to 250 ml / min, and transfer the conveyor-type rotary algae The biofilm system is combined with the aeration system, so that the lower end of the algae biofilm system is immersed in the wastewater in the aeration tank,...

Embodiment 3

[0065] In this embodiment, a bacterial and algae rotating biofilm reactor system based on phosphorus and nitrogen removal includes two parts: an activated sludge system and a drum type rotating algae biofilm system.

[0066] The main body of the activated sludge system is an aeration tank (1), which also includes activated sludge (2) and a blower (3). The aeration main pipe (5) and the aeration branch pipe (4) are located at the bottom of the aeration tank.

[0067] The drum type rotary algae biofilm system includes a drum algae film (14), a stirring blade (15), a drum scraper (16), a drum microalgae collection tank (17), a drum supporting steel frame (18), a drum motor (19), Membrane strut (13) and shaft (20).

[0068] The applied process steps are

[0069] Step 1: Cultivation of Microalgae

[0070] The well-growing microalgae were transferred to the microalgae medium for culture, and cultured in a light shaker with a light intensity of 4000Lux, a temperature of 28°C, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com