Lightweight lath for building and preparation method of lightweight lath

A light-weight technology for construction, applied in chemical instruments and methods, applications, household walls, etc., can solve the problems of mechanical strength, impact resistance, sound insulation, sound absorption, thermal insulation and other unsatisfactory problems, and achieve excellent thermal insulation performance, High mechanical strength, good sound insulation and sound absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

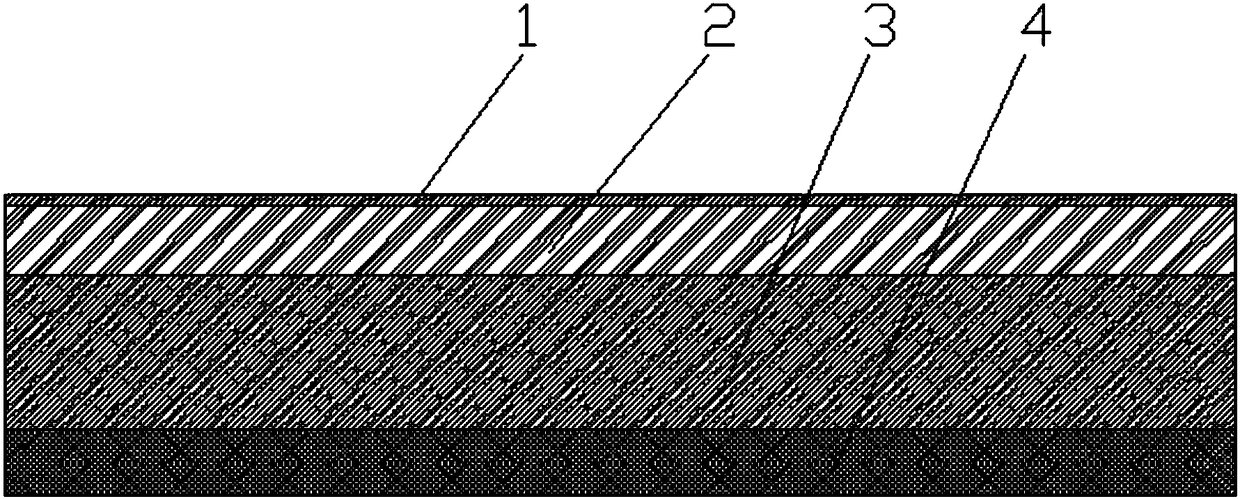

[0026] A lightweight slat for construction, comprising a paint spray layer 1, a straw board 2, a cement pressure board 3 and a polystyrene foam board 4, the paint spray layer 1 is located on the outer surface of the straw board 2, and the cement pressure board 3 Placed between the straw board 2 and the polystyrene foam board 4, the weight parts of the raw materials of the straw board 2 are as follows: 99 parts of plant straw, 38 parts of water glass, 15 parts of hemp knife ash, 8 parts of waste tempered glass powder, 7 parts of beidellite, the weight parts of raw materials of the cement pressure plate 3 are as follows: 80 parts of spherical quartz powder, 120 parts of cement, 60 parts of white plaster mud, 40 parts of pearl sand, 30 parts of sepiolite wool and 20 parts of paper bar ash The raw material parts by weight of the polystyrene foam board 4 are as follows: 20 parts of polystyrene, 7 parts of fluff powder, 25 parts of polyester pulp, 7 parts of nano zirconium silicate, ...

Embodiment 2

[0041] A lightweight slat for construction, comprising a paint spray layer 1, a straw board 2, a cement pressure board 3 and a polystyrene foam board 4, the paint spray layer 1 is located on the outer surface of the straw board 2, and the cement pressure board 3 Placed between the straw board 2 and the polystyrene foam board 4, the raw materials of the straw board 2 are as follows: 118 parts of plant straw, 47 parts of water glass, 17 parts of hemp knife ash, 10 parts of waste tempered glass powder, 8.5 parts of beidellite, the weight parts of the raw materials of the cement pressure board 3 are as follows: 86 parts of spherical quartz powder, 126 parts of cement, 67 parts of white plaster mud, 51 parts of pearl sand, 37 parts of sepiolite wool and 26 parts of paper bar ash The raw material parts by weight of the polystyrene foam board 4 are as follows: 30 parts of polystyrene, 10 parts of fluff powder, 32 parts of polyester pulp, 9 parts of nano zirconium silicate, 1.5 parts o...

Embodiment 3

[0056] A lightweight slat for construction, comprising a paint spray layer 1, a straw board 2, a cement pressure board 3 and a polystyrene foam board 4, the paint spray layer 1 is located on the outer surface of the straw board 2, and the cement pressure board 3 Placed between the straw board 2 and the polystyrene foam board 4, the weight parts of the raw materials of the straw board 2 are as follows: 136 parts of plant straw, 56 parts of water glass, 20 parts of hemp knife ash, 12 parts of waste tempered glass powder, 10 parts of beidellite, the weight parts of raw materials of the cement pressure board 3 are as follows: 93 parts of spherical quartz powder, 133 parts of cement, 75 parts of white plaster mud, 65 parts of pearl sand, 45 parts of sepiolite wool and 32 parts of paper bar ash The raw material parts by weight of the polystyrene foam board 4 are as follows: 40 parts of polystyrene, 13 parts of fluff powder, 40 parts of polyester pulp, 12 parts of nano zirconium silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com