A kind of broken wood shaving device for building materials

A technology for shavings and wood chips, which is applied in the field of wood chipping devices for building materials, can solve problems such as waste and discard, and achieve the effect of avoiding waste of wood and excessive felling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

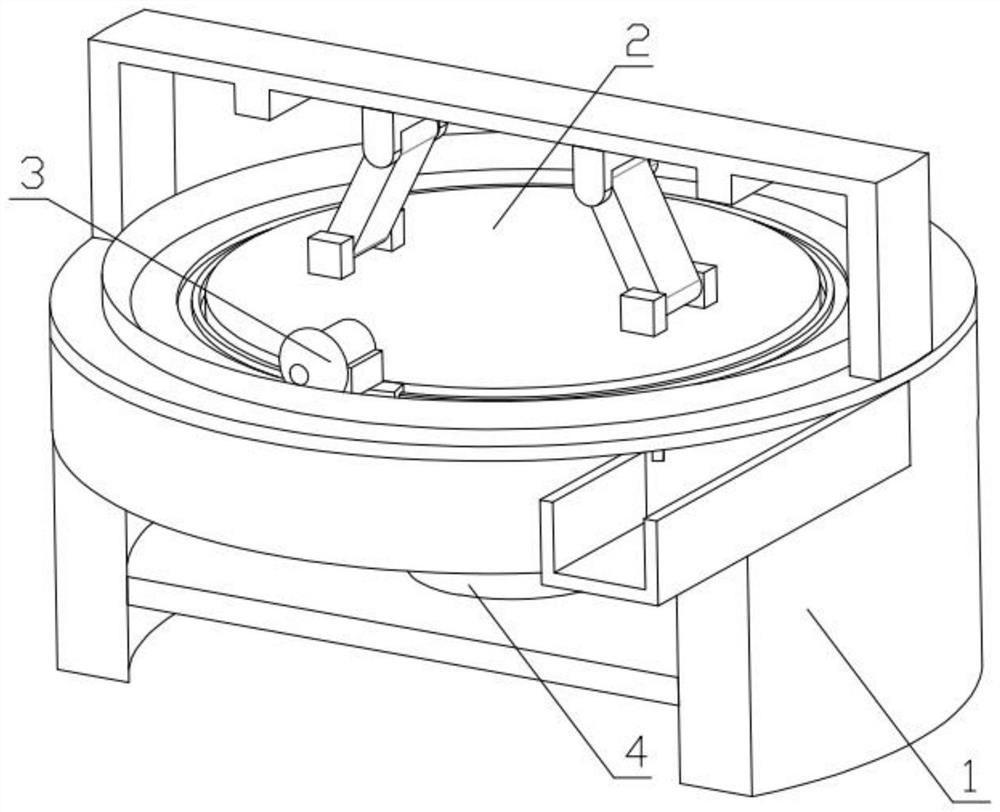

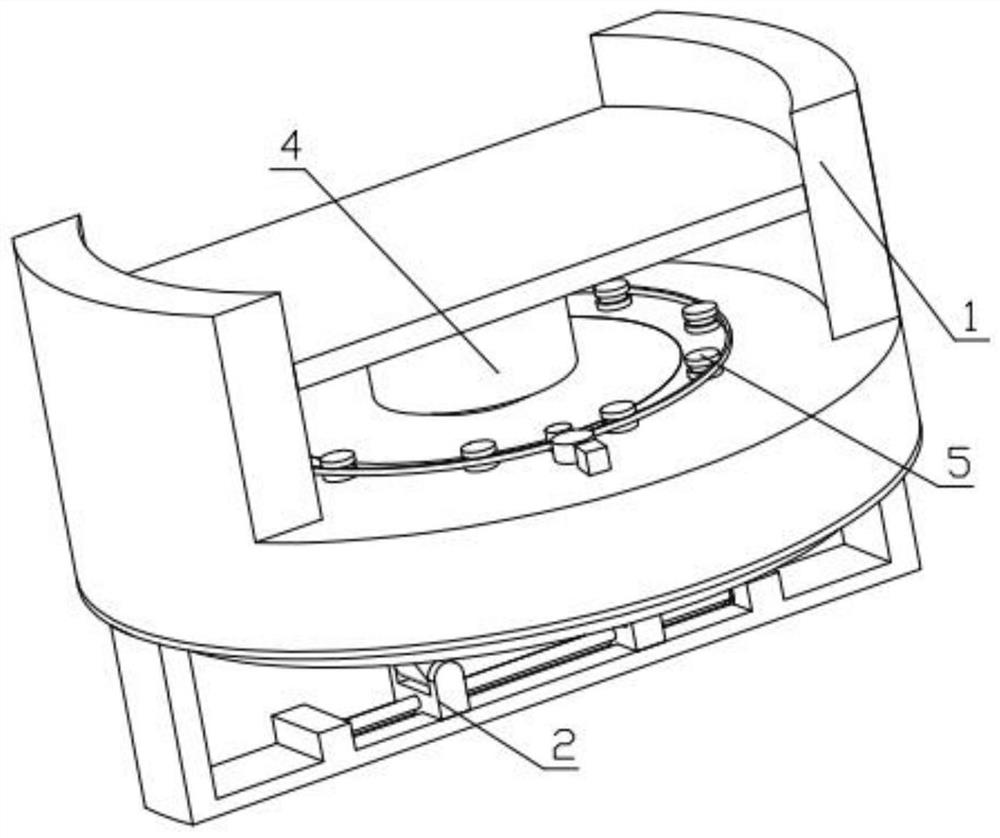

[0039] Combine below Figure 1-17 Illustrating this embodiment, a broken wood shaving device for building materials includes a circular cavity base 1, an upper sealing top cover 2, a shavings pushing mechanism 3, a rotating mechanism 4 and a shavings mechanism 5. The upper sealing top cover 2 It is fixedly installed on the circular cavity base 1, the rotating mechanism 4 is fixedly installed on the circular cavity base 1, the shavings mechanism 5 is fixedly installed on the circular cavity base 1, and the shavings pushing mechanism 3 is fixedly installed on the circular cavity body base 1.

specific Embodiment approach 2

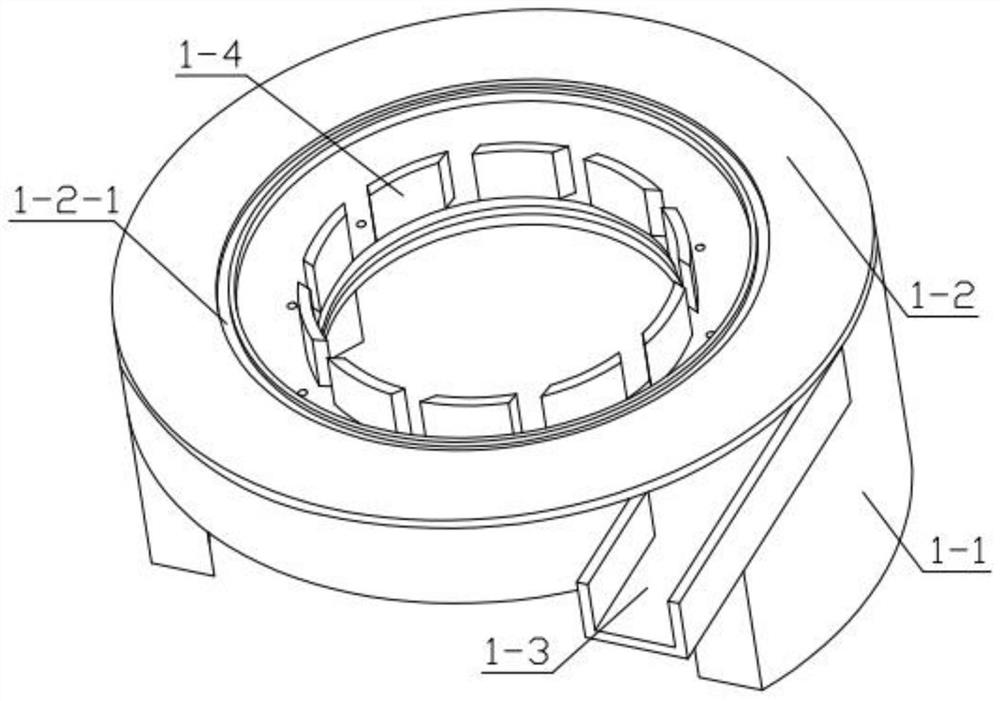

[0040] Combine below Figure 1-17 This embodiment is described. This embodiment further describes Embodiment 1. The circular cavity base 1 includes a main cavity base 1-1, an annular cover 1-2, a discharge chute 1-3, and an arc-shaped spacing plate. 1-4, a discharge chute 1-3 is fixedly installed on the base 1-1 of the main cavity, an annular cover 1-2 is fixedly installed on the base 1-1 of the main cavity, and an annular chute is arranged on the annular cover 1-2 1-2-1, the arc spacing plate 1-4 is fixedly installed on the base 1-1 of the main cavity.

specific Embodiment approach 3

[0041] Combine below Figure 1-17 This embodiment will be described. This embodiment will further describe Embodiment 2. The upper sealing top cover 2 includes a U-shaped frame 2-1, a circular sealing cover 2-2, hinged legs 2-3, and a slider 2- 4. Bidirectional threaded rod 2-5, motor 2-6 for sealing, motor 2-6 for sealing is fixedly installed on U-shaped frame 2-1, and the output end of motor 2-6 for sealing is fixedly installed with bidirectional threaded rod 2- 5. The other end of the two-way threaded rod 2-5 is rotatably installed in the groove set on the U-shaped frame 2-1. In the groove provided on the U-shaped frame 2-1, the slider 2-4 is hinged with the hinged leg 2-3, the other end of the hinged leg 2-3 is hinged with the circular sealing cover 2-2, and the U-shaped frame 2 -1 is fixedly mounted on the ring cover 1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com